Magnesium refining process in titanium sponge production process

A production process, sponge titanium technology, applied in the field of magnesium refining, to achieve the effect of reducing distillation time, improving turnover efficiency, and reducing reduction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

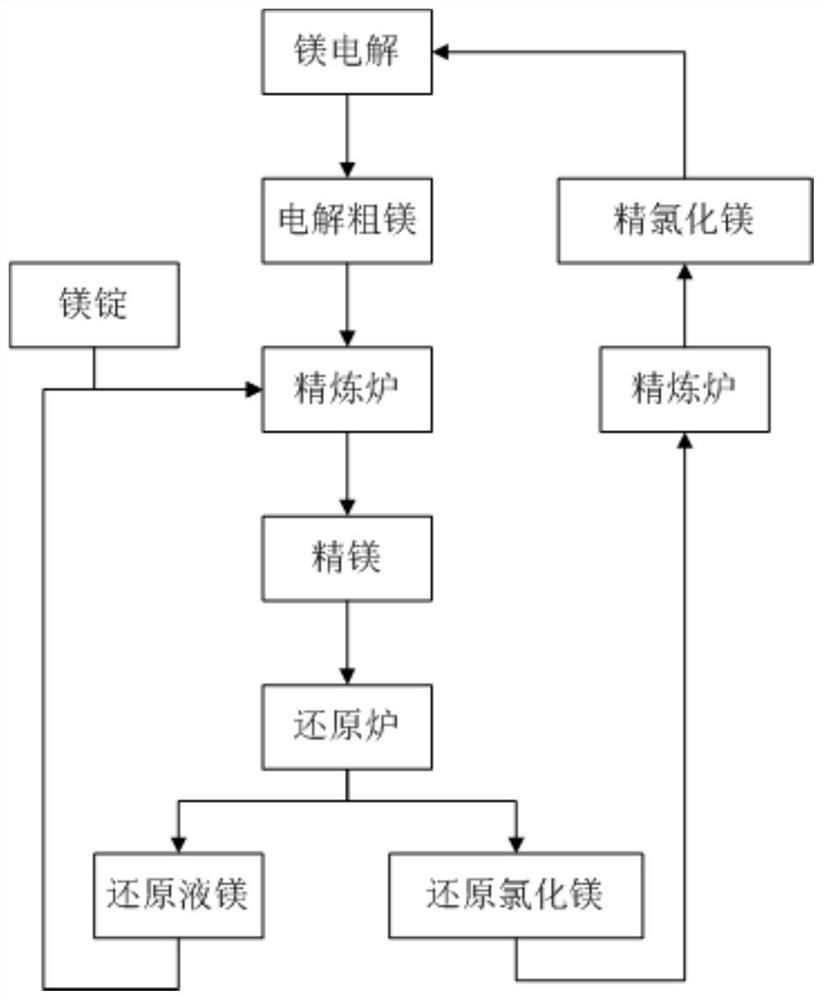

[0028] see attached figure 1 As shown, a refining process of magnesium in the production process of sponge titanium, the specific process flow is as follows:

[0029] Step 1: in the production process of sponge titanium, the reduction liquid magnesium and reduced magnesium chloride produced in the reduction furnace after the reduction of the sponge titanium is completed are respectively transported to the first refining furnace and the second refining furnace;

[0030] Step 2: input the purchased magnesium ingots into the smelting furnace for smelting treatment, the smelting temperature is 651 ° C, and then stand for 4 hours, and after the standing is completed, add the standing magnesium to the first refining furnace;

[0031] Refining the reduced magnesium chloride through the second refining furnace, the refining temperature is 700°C, and the refining time is 4 hours, to obtain refined magnesium chloride; electrolyze the refined magnesium chloride to obtain electrolytic cru...

Embodiment 2

[0037] see attached figure 1 As shown, a refining process of magnesium in the production process of sponge titanium, the specific process flow is as follows:

[0038] Step 1: in the production process of sponge titanium, the reduction liquid magnesium and reduced magnesium chloride produced in the reduction furnace after the reduction of the sponge titanium is completed are respectively transported to the first refining furnace and the second refining furnace;

[0039] Step 2: input the purchased magnesium ingots into the smelting furnace for smelting treatment, the smelting temperature is 700 ° C, and then stand for 3 hours, and after the standing is completed, add the standing magnesium to the first refining furnace;

[0040] The reduced magnesium chloride is refined through the second refining furnace, the refining temperature is 720 ° C, and the refining time is 3 hours to obtain refined magnesium chloride; the refined magnesium chloride is electrolyzed to obtain electroly...

Embodiment 3

[0046] see attached figure 1 As shown, a refining process of magnesium in the production process of titanium sponge, the specific process flow is as follows:

[0047] Step 1: in the production process of sponge titanium, the reduction liquid magnesium and reduced magnesium chloride produced in the reduction furnace after the reduction of the sponge titanium is completed are respectively transported to the first refining furnace and the second refining furnace;

[0048] Step 2: input the purchased magnesium ingots into the smelting furnace for smelting treatment, the smelting temperature is 680 ° C, and then stand for 3.5 hours, and after the standing is completed, add the standing magnesium to the first refining furnace;

[0049] Refining the reduced magnesium chloride through the second refining furnace at a refining temperature of 710°C and a refining time of 3.5 hours to obtain refined magnesium chloride; electrolyzing the refined magnesium chloride to obtain electrolytic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com