Softening machine with liquid feeding device

A technology of softening machine and liquid pump, which is applied in the field of softening machine, can solve the problems that the mixing effect of softening liquid for knitted sweaters is not obtained effectively, and the quality of the liquid on knitted sweaters is not clear, so as to achieve the effect of promoting mixing and mixing, improving the qualified rate, Facilitate the effect of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

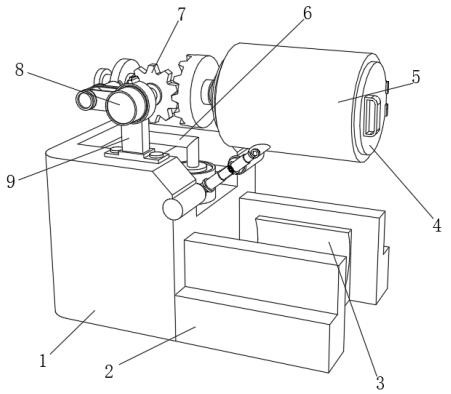

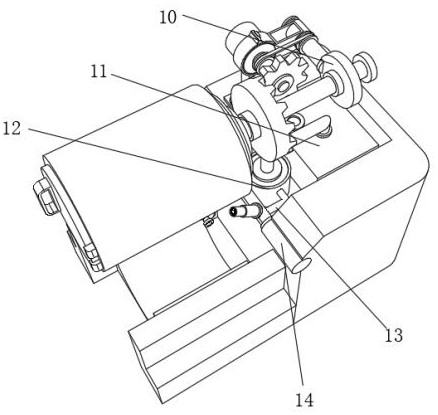

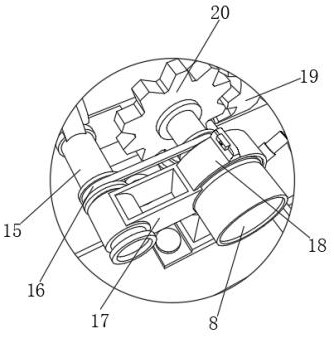

[0032] A softener with a liquid feeding device, such as Figure 1-4 As shown, it includes a main body box 1, one side outer wall of the main body box 1 is fixed with two brackets 2 by bolts, and the opposite side outer walls of the two brackets 2 are fixed with the same arc-shaped placement rack 3 by bolts, the main body The top outer wall of the box 1 is provided with an installation groove, the inner wall of the installation groove is fixed with the material box 11 by bolts, and the liquid pump 12 is fixed by bolts on the top side of the installation groove, and the outer wall of the main box 1 close to the liquid pump 12 has two slots , and the inner walls of the two slots are inserted with installation cylinders 14, and the opposite sides of the two installation cylinders 14 are connected with connecting pipes through threads, and the input end and output end of the liquid pump 12 are respectively connected by threads. , the end of the guide pipe 13 is connected with one s...

Embodiment 2

[0038] A softener with a liquid feeding device, such as Figure 5 As shown in the figure, in order to promote the mixing efficiency of the sweater; this embodiment makes the following improvements on the basis of Embodiment 1: the inner circumferential wall of the guide cylinder 5 is connected with a rotating shaft 24 through threads, and the two ends of the circumference of the rotating shaft 24 are respectively connected by threads. The filter screen 23 is fixed, the end of the rotating shaft 24 is bonded to the limit roller 26, and the middle circumference of the rotating shaft 24 is provided with a corrugated protrusion 25; when the sweater rotates and swings in the guide cylinder 5, the filter screen 23 can effectively The swinging impact force of the sweater is weakened, and the large rolling range of the sweater in the guide cylinder 5 can cause damage to itself. At the same time, the corrugated protrusions 25 also play a role in massaging the sweater to ensure the mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com