In-situ combustion and explosion fracturing method for methane in shale gas reservoir fractures

A technology for blasting fracturing and shale gas, which is used in earth-moving drilling, wellbore/well components, and production fluids. Large and other problems, to achieve the effect of improving the seepage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

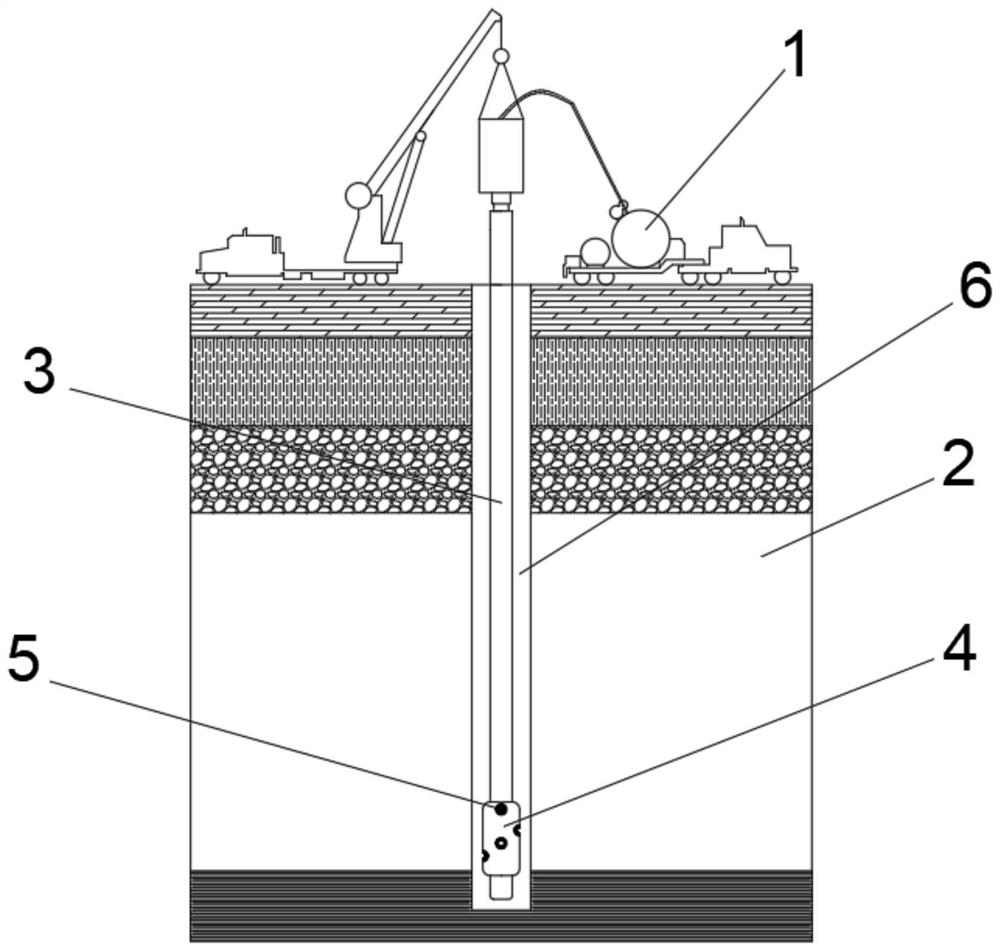

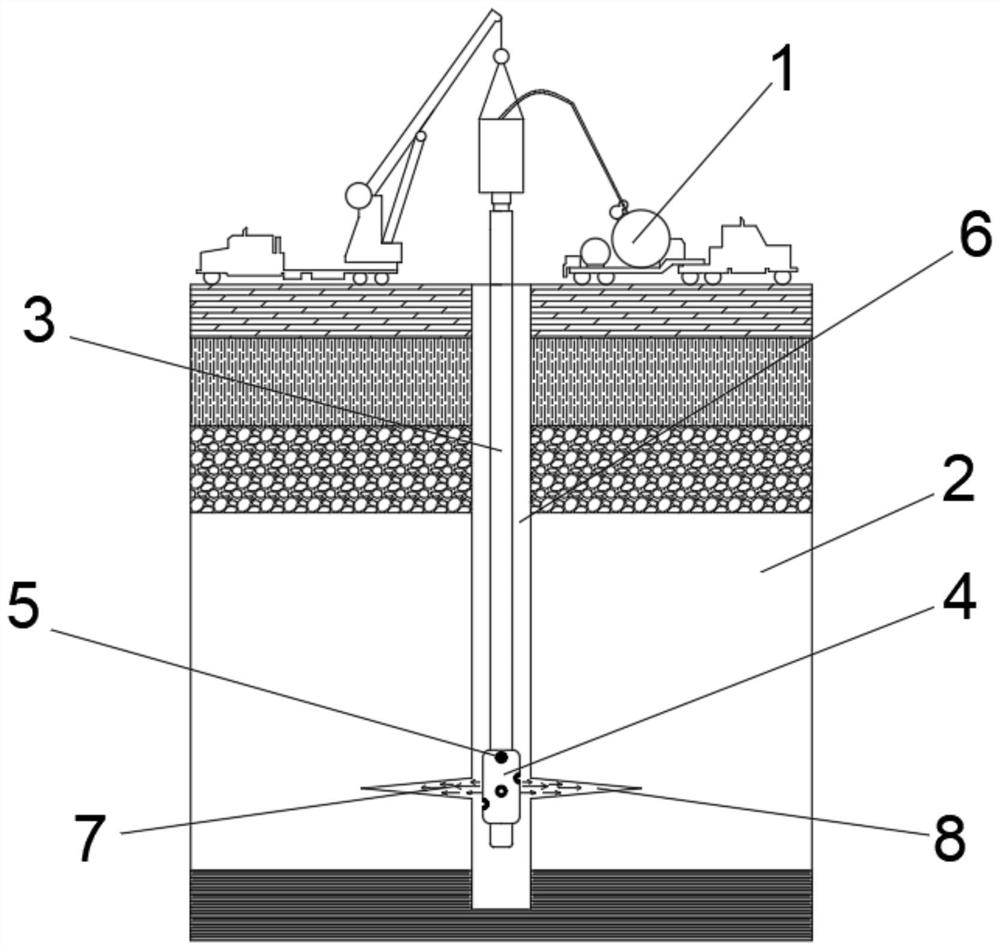

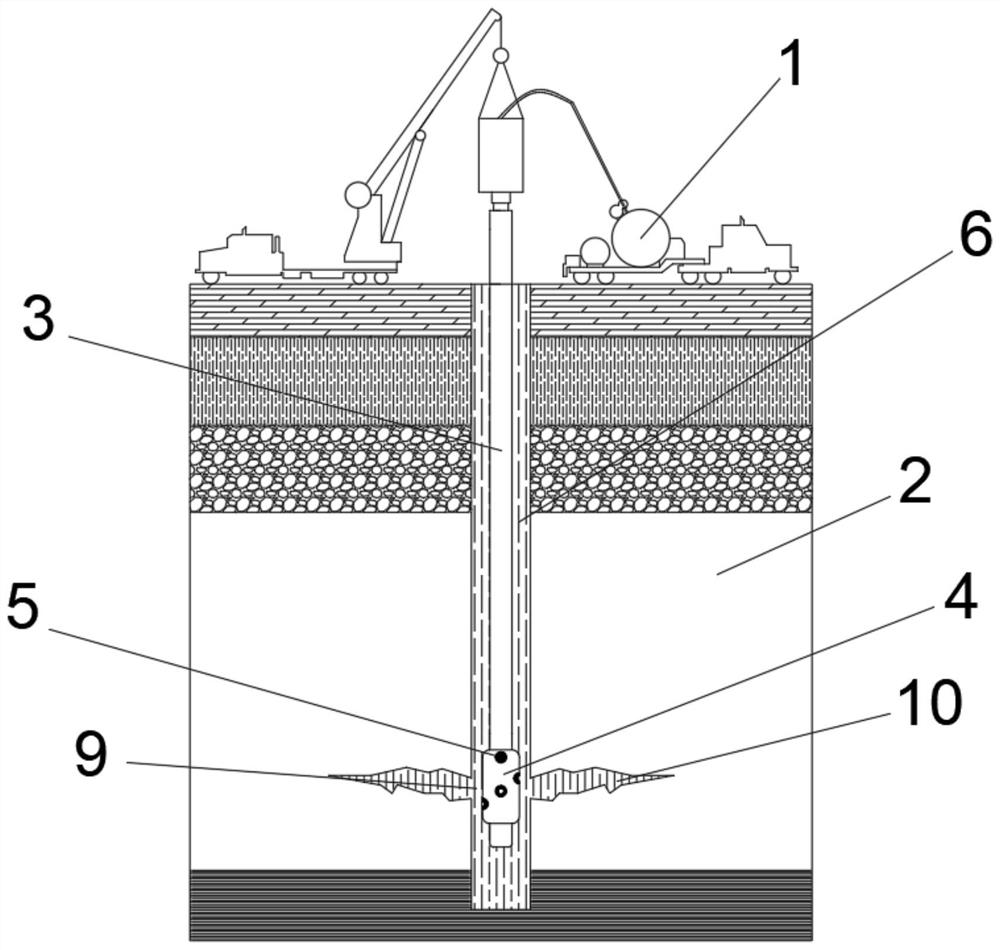

[0041] like Figure 1 to Figure 8 As shown, the present invention provides a method for in-situ blasting and fracturing of methane in a shale gas reservoir, which specifically includes the following steps;

[0042] Step 1: Preparatory work;

[0043] S11: Determine the rock-breaking and fracturing interval and fracturing position of the shale gas reservoir to be produced according to the geological and wellbore 6 survey data;

[0044] S12: Build the ground working system 1, connect the ground working system 1 to the coiled tubing 3, and then lower the fracturing tool 4 to the target working position through the coiled tubing 3. The fracturing tool 4 has a built-in ignition electrode 5, and the ignition electrode 5 passes through the coiled tubing 3. The cable built in the coiled tubing 3 is connected to the ignition device in the ground work system 1;

[0045] Step 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com