Test device and test method for live oil pipe hydraulic cylinder with built-in piston rod

A test device and live oil pipe technology, applied in the field of hydraulic cylinders, can solve the problems of high cost of test benches, unaffordable enterprises, large installed flow rate and installed power of test benches, etc., and achieve a simple and reliable structure, compact structure, and strong bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

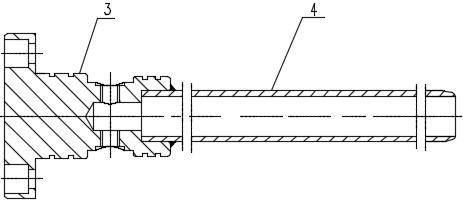

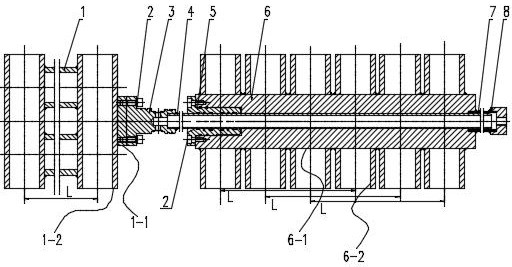

[0040] Combine Figure 1 to Figure 4 It shows, a live oil tube hydraulic cylinder test device with a built -in piston rod, oil pipe seat 3 and active oil pipe 4 through welding connection, and the radius of the live oil pipe 4 is arranged with M16 × 1.5 oil port to the trial activity to try the test activity. Oil pipe 4 tests.

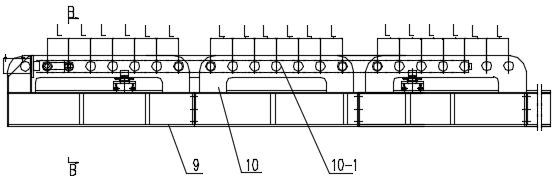

[0041] The test tables include rack 9, and the side plate 10 with symmetrical layout on the rack 9. There are multiple sets of relative sales holes 10-1 on the side board 10. Most pairs of the spacing between the tail positioning sleeve 1-2, the distance between the front position 6-2 and the spacing between 10-1 of the 10-1 of the multi-group side plate 10-1.

[0042] The main body of the rear connection device 1 is in the shaped shape, which includes the connection seat 1-1, the oil pipe seat 3 and the connection seat 1-1 to fix the connection through the screw 2. Connect 1-1 on the left side of two pairs of more than two panels 10-1 on the tail positioni...

Embodiment 2

[0047] On the basis of the above -mentioned Examples, a daily hydraulic cylinder test method, including the following steps:

[0048] A. Fix the oil pipeline 3 on the connection seat 1-1 connected to the tail connection device; the tail positioning sleeve 1-2 of the tail connection device 1 through the axis cover 11 and the sales axis 12 and the side board 10 on the test table 10 Sales holes 10-1 connection; two pairs of tail positioning sleeve 1-2 connection guarantees that there is no rotation of the live oil tube due to hinge rotation;

[0049] B. Put the live oil pipe 4 in the main body 6-1 center hole of the guide cover 5 and the front connection device 6; 10-1 connection of the side plate 10-1 on the test table;

[0050] C. Put the oil port and joint 8 on the oil port 3 into the hydraulic system; to inject hydraulic oil into the live oil pipe 4 through the hydraulic system, the intermediate radial direction of the actual oil pipe 4 will generate a certain amount. Disposal in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com