Waste heat recovery boiler suitable for maleic anhydride device

A waste heat recovery boiler, maleic anhydride technology, applied in the direction of indirect heat exchanger, heat exchanger type, heat exchange equipment, etc., can solve the problem of poor pressure bearing effect, it is difficult to be compatible with the diversion effect and the pressure bearing effect, and the diversion effect is poor. and other problems, to achieve the effect of good diversion effect, strong pressure bearing capacity and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and examples. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

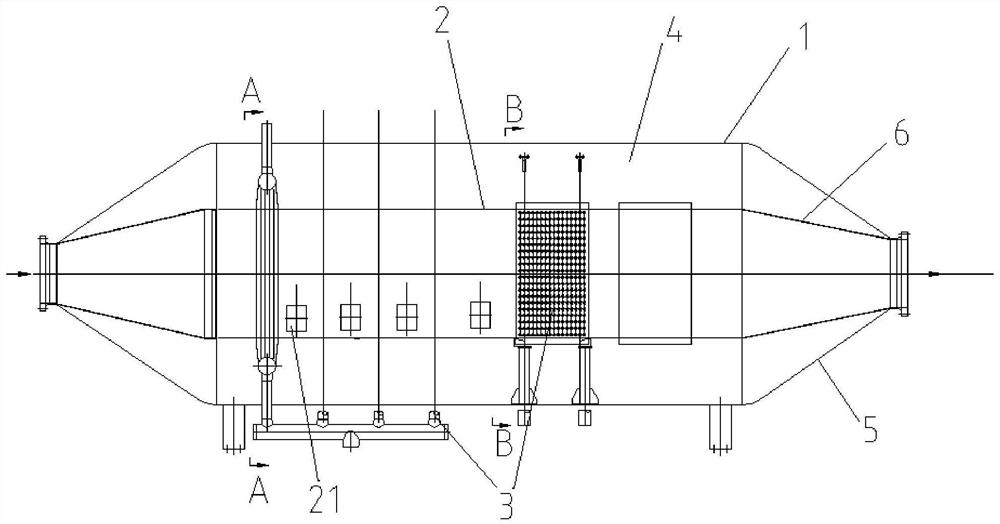

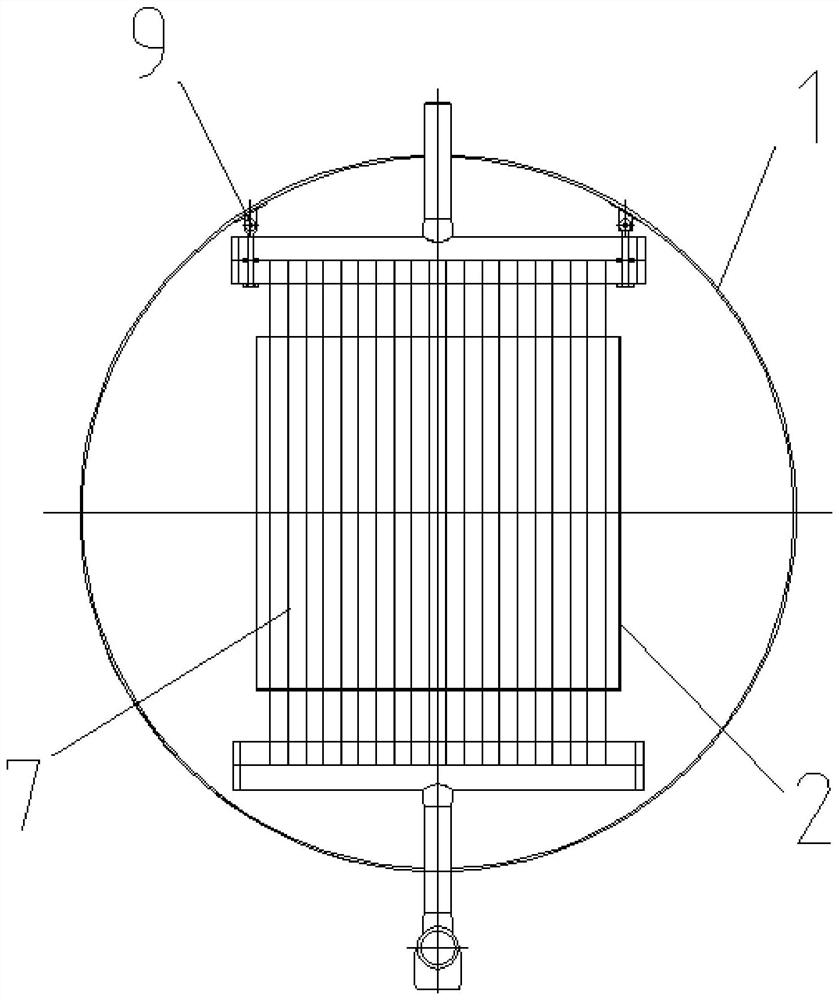

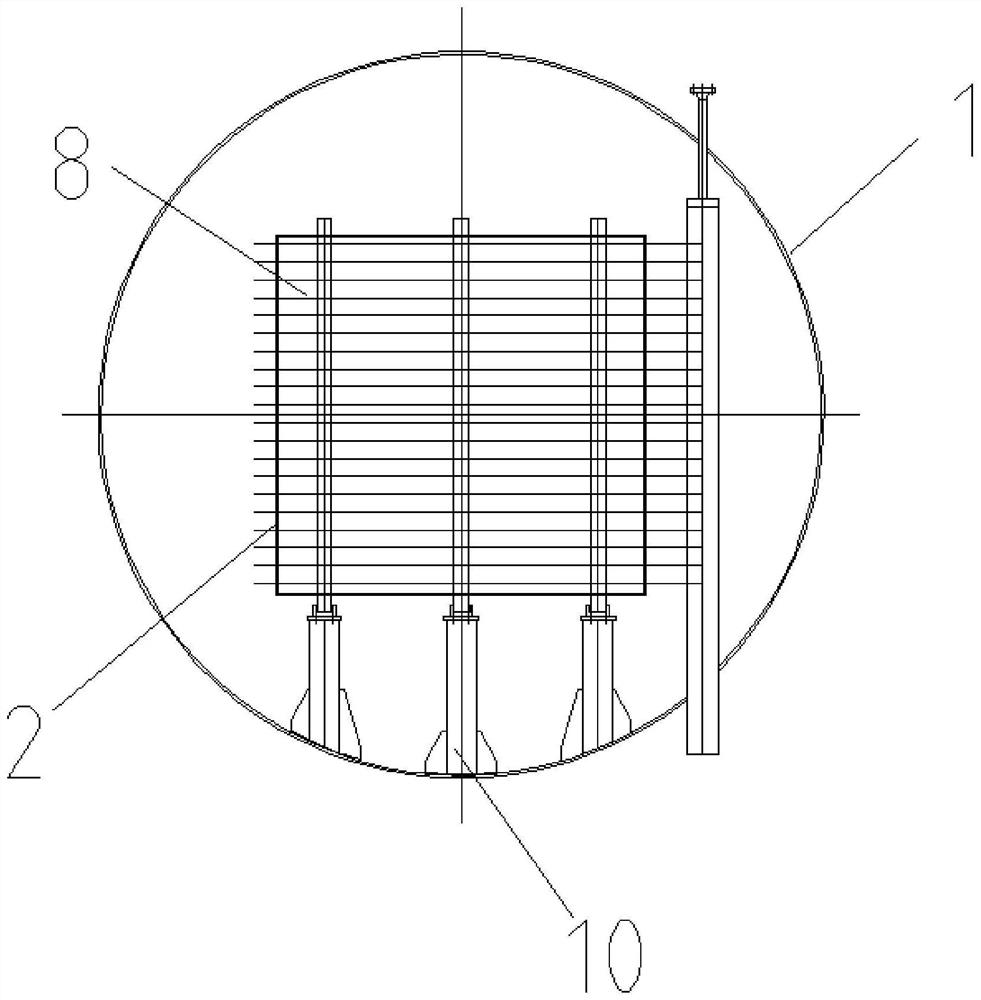

[0030] The waste heat recovery boiler of this embodiment is suitable for maleic anhydride plant, such as Figure 1 to Figure 3 As shown, it includes an outer pressure-bearing cylinder 1, an inner diversion cylinder 2 and multiple groups of heat exchange tube groups 3, each group of heat exchange tube groups 3 is arranged along the radial direction of the outer pressure-bearing cylinder 1, and the multiple groups of heat exchange tube groups 3 The inlet and outlet respectively pass through the side wall of the outer pressure-bearing cylinder 1 in a sealed manner. The outer pressure-bearing cylinder 1 is cylindrical, and the inner flow guide cylinder 2 is inserted into the outer pressure-bearing cylinder 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com