Vertical loading wheel tester for asphlat pavement

A technology of asphalt pavement and tester, which is applied in the direction of measuring the permanent deformation force by measuring the gauge, etc., can solve the problems of rutting test that cannot perform linear motion, inaccurate test data, and different test conditions, and achieves a wide test range. , Accurate test data, multi-functional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to these embodiments.

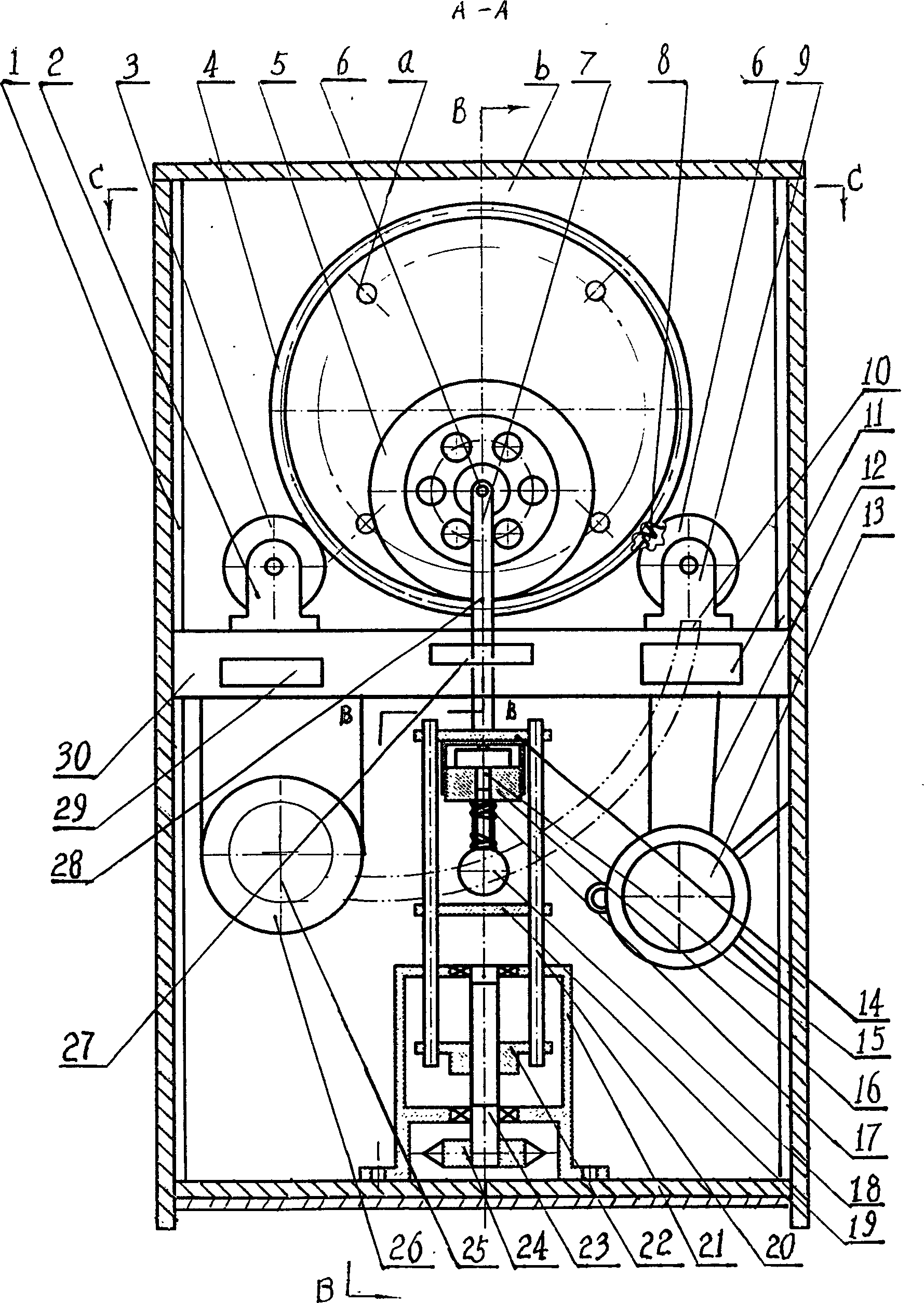

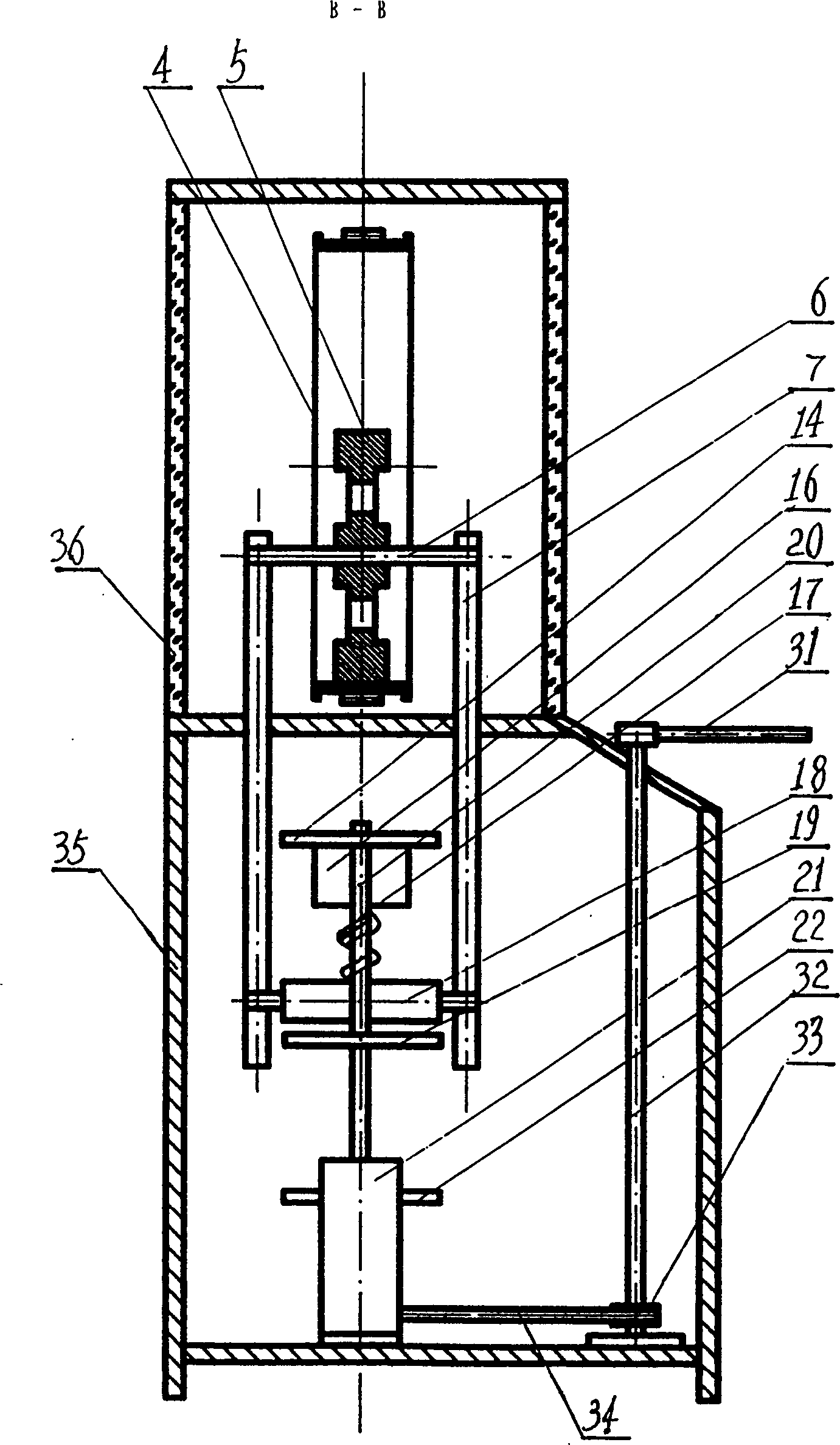

[0017] Figure 1~4 A structural schematic diagram of an embodiment of the present invention is given. exist Figure 1~4 Among them, the asphalt pavement vertical ring road load tester of this embodiment includes: a running mechanism, a force-adding mechanism, and a constant temperature mechanism arranged on the support 1 . The upper, lower, left, right, front and rear of the support 1 are covered with a cover plate 35, and an instrument panel 30 is installed on the upper front side of the support 1.

[0018] The operating mechanism of the present embodiment is made up of left support wheel support 2, support wheel 3, track wheel 4, load wheel 5, load wheel shaft 6, transmission wheel 8, right support wheel support 9, gearbox 11, belt 12, speed regulating motor 13 , Belt pulley 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com