Process and equipment for preparing aluminium polychloride

A technology of polyaluminum chloride and aluminum hydroxychloride, applied in aluminum chloride, aluminum halide and other directions, can solve the problems of long production cycle, slow reaction speed of hydrochloric acid and aluminum hydroxide, complex production process and production equipment, etc. Strong sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

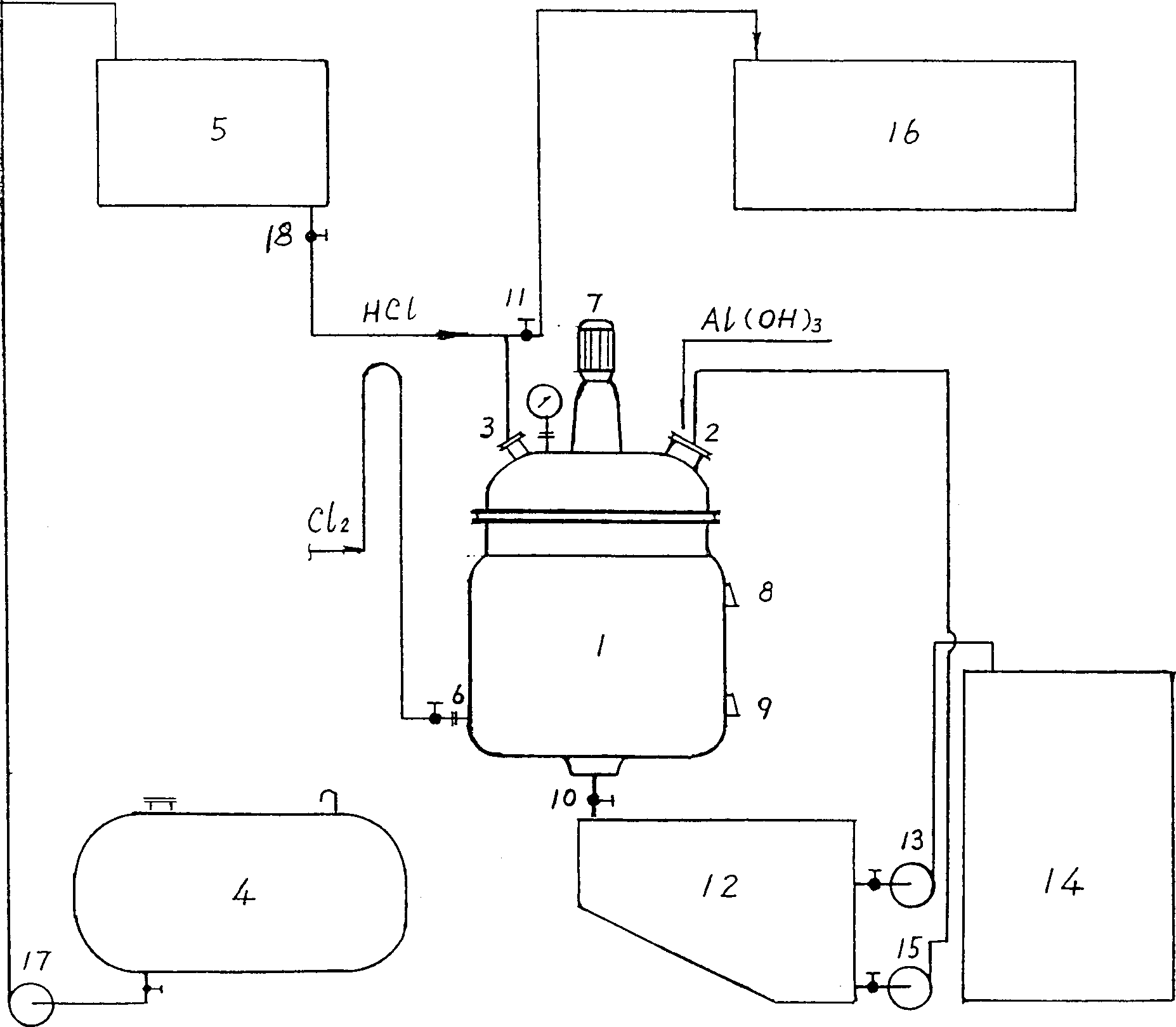

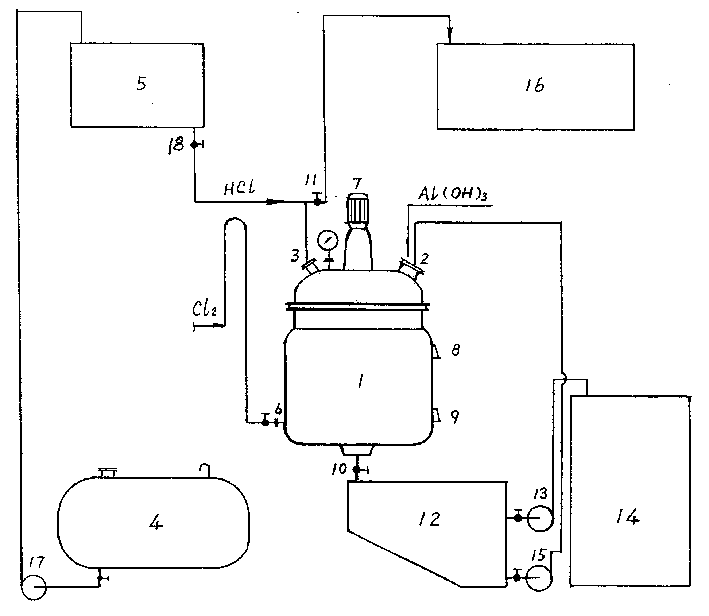

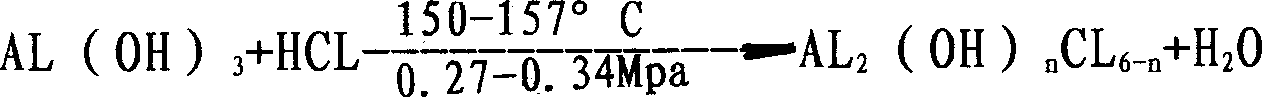

[0020] Such as figure 1 As shown, when using hydrochloric acid and aluminum hydroxide as raw materials to utilize the present invention to produce polyaluminum chloride, at first hydrochloric acid and aluminum hydroxide are fed by hydrochloric acid feeding port 3 and Aluminum hydroxide feeding port 2 is put into reactor 1, wherein the concentration of hydrochloric acid should be greater than or equal to 31%. For accurately controlling the input amount of hydrochloric acid, the hydrochloric acid pump 17 should be used to pump the hydrochloric acid from the hydrochloric acid storage tank 4 into the hydrochloric acid metering cylinder 5 and then put into the reaction kettle 1 through the valve 18 after metering. After closing the feeding port 2 and the feeding port 3, feed circulating hot water into the hot water jacket of the reactor 1 through the circulation inlet 8 and the circulation outlet 9, so that the material in the reactor 1 is maintained at 30-40°C. At the same time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com