Double bottom fermentation technology

A new process, double-wheel technology, applied in the field of brewing and fermentation, can solve problems such as the decrease of taste quality, the increase of koji medicine intensified fermentation to produce ester, and the increase of production cost, so as to save koji medicine, ensure the quality of wine, and improve the utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

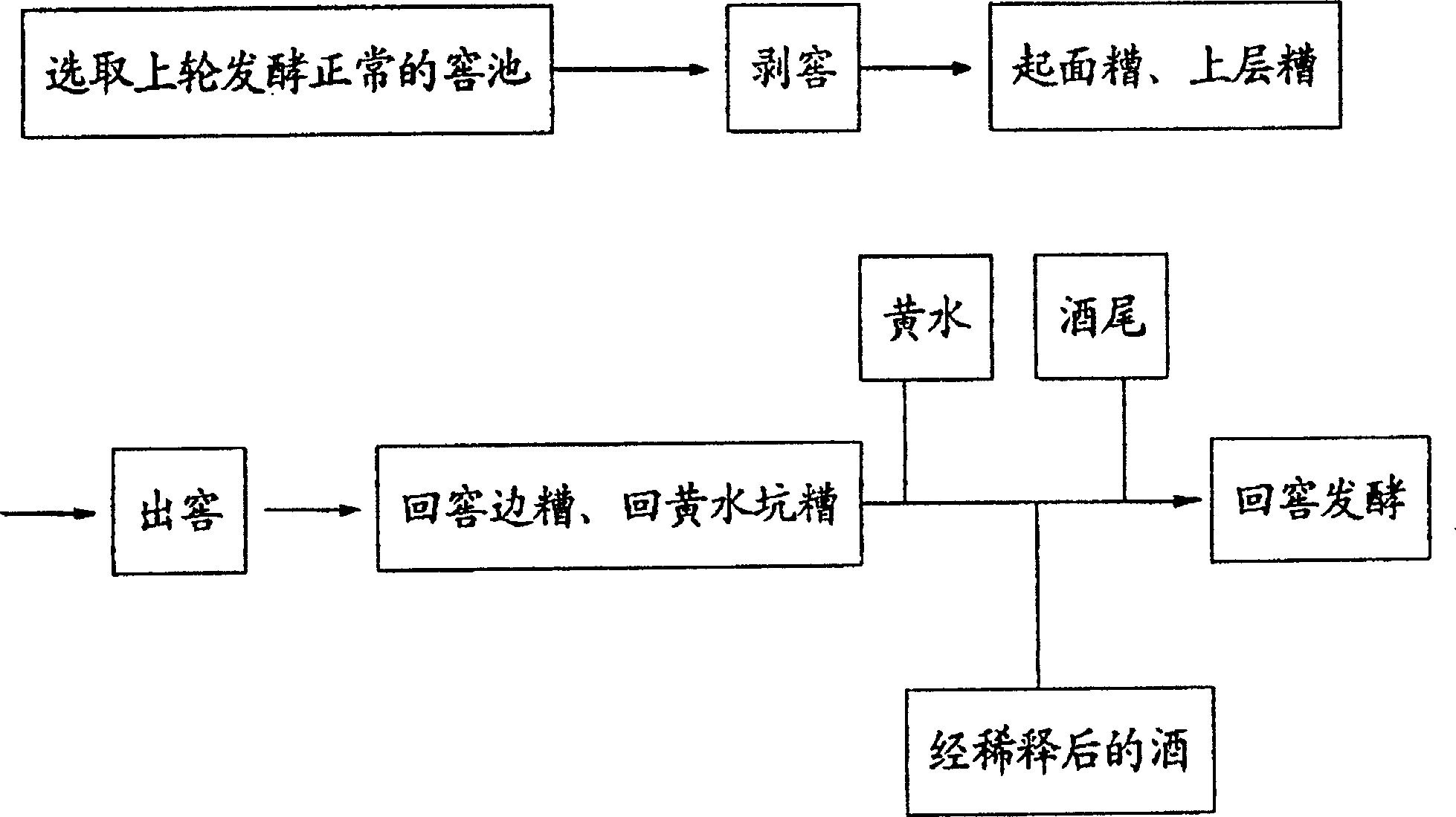

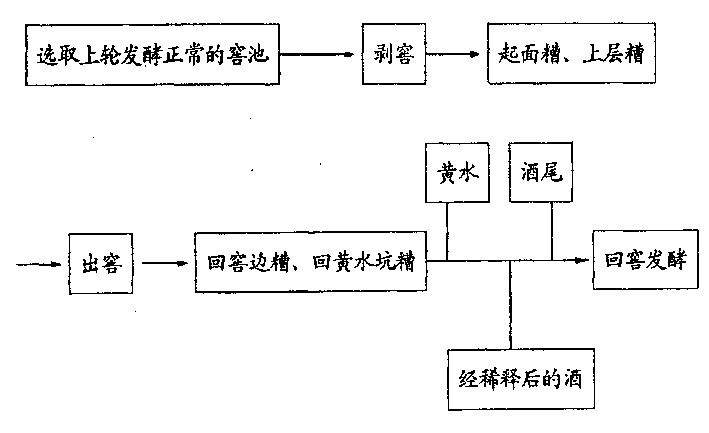

Method used

Image

Examples

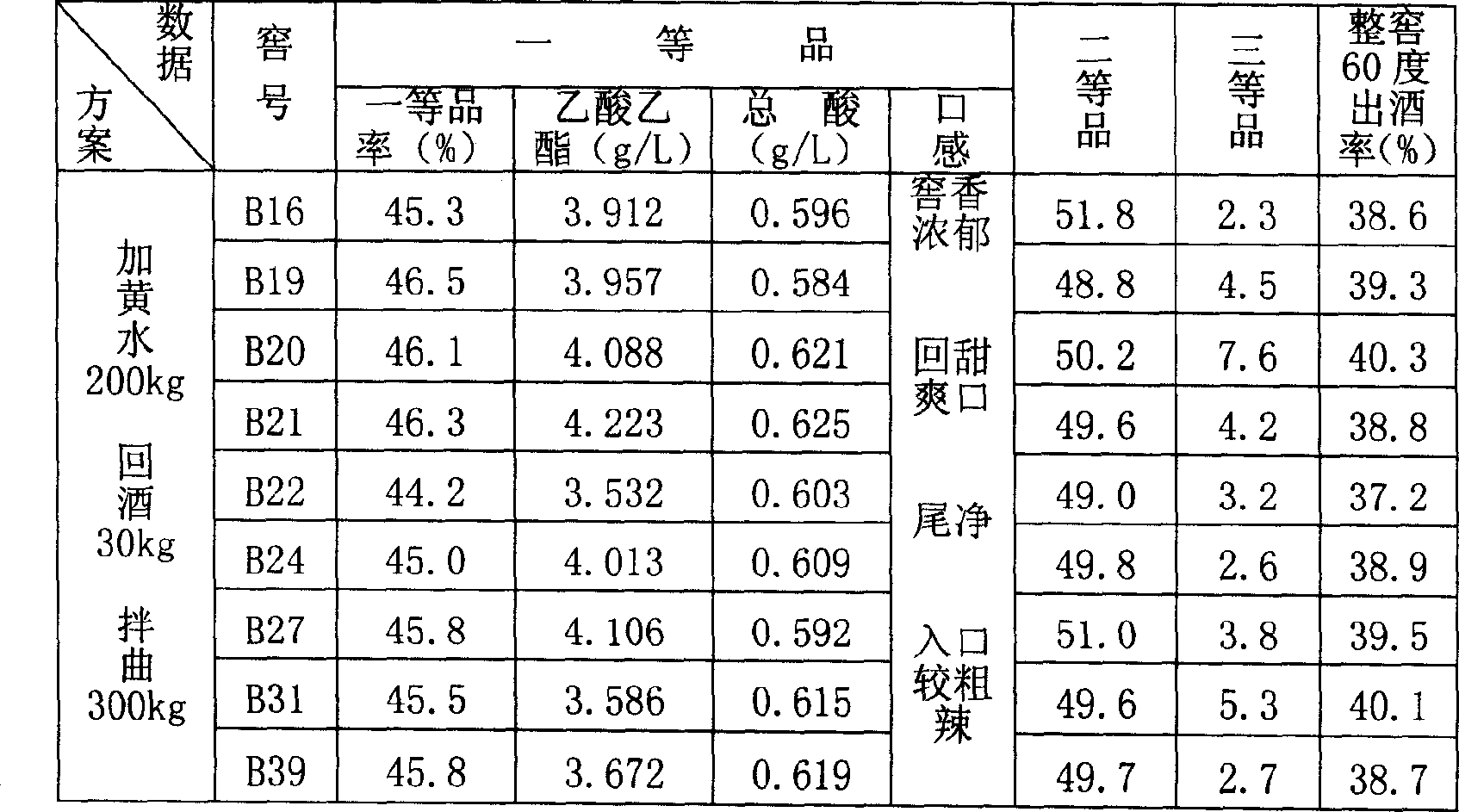

Embodiment 1

[0026] Ingredients:

[0027]

[0028] Rice husk 20%

[0029] Red grains 33%

[0030] Water 113%

[0031] Dosage of returning grains: From the lower part of the cellar that has been fermented in the previous round, take 4 retorts of the mother's grains and use them as the mother's grains for fermentation in this cellar.

[0032] Dosage of returning yellow water: Take the normal fermented yellow water with an acidity of 4.0g / L, and the dosage is 35kg per retort.

[0033] Dosage for returning wine: take 70% (v / v) third-grade grain wine, and the dosage is 9kg per retort.

[0034] Dosage for back-to-wine tail: Take the bottom dregs tail wine with normal fermentation, and the dosage is 38kg per retort.

[0035] Liquor: first-class product rate 44.12%

[0036] Ethyl caproate content 3.99g / L

[0037] Total acid 0.58g / L

[0038] Taste Strong cellar aroma, sweet and refreshing, with a clean finish

[0039] Second-class product rate 50.1%

[0040] Third-class product rate 5.7...

Embodiment 2

[0043] Ingredients:

[0044]

[0045] Rice husk 20%

[0046] Red grains 33%

[0047] Water 113%

[0048] Dosage of returning grains: From the lower part of the cellar that has been fermented in the previous round, take 4 retorts of the mother's grains without extracting the wine, and use them as the mother's grains for fermentation in this cellar;

[0049] Dosage of back-to-yellow water: Take the normal fermented yellow water with an acidity of 4.2g / L, and the dosage is 45kg per retort;

[0050] Dosage for returning wine: take 70% (V / V) third-grade grain wine, and the dosage is 11kg per retort;

[0051] Dosage for back-to-wine tail: Take the bottom dregs wine with normal fermentation, and the dosage is 42kg per retort;

[0052] Liquor: 48% first-class product rate

[0053] Ethyl caproate content 4.12g / L

[0054] Total acid 0.63g / L

[0055]Taste Strong cellar aroma, sweet and refreshing, with a clean finish

[0056] Second-class product rate 49%

[0057] Third-class...

Embodiment 3

[0060] Ingredients:

[0061] Sorghum 66%

[0062] Corn 10%

[0063] Rice 10%

[0064] Glutinous rice 6%

[0065] Wheat 8%

[0066] Rice husk 20%

[0067] Red grains 33%

[0068] Water 113%

[0069] Dosage of returning grains: from the lower part of the cellar that has been fermented in the previous round, take 4 retorts of the mother tank without taking wine as the mother's grains for fermentation in this cellar; dosage of returning yellow water: take the one with an acidity of 4.1g / L for normal fermentation Yellow water, the dosage is 40Kg per steamer;

[0070] Dosage of returning wine: take 70% (v / v) third-grade grain wine, and the dosage is 10Kg per retort;

[0071] Dosage for back-to-wine tail: Take the bottom dregs tail wine with normal fermentation, and the dosage is 40Kg per retort;

[0072] Liquor: 45.5% first-class rate

[0073] Ethyl caproate content 3.996g / L

[0074] Total acid 0.598g / L

[0075] Taste Strong cellar aroma, sweet and refreshing, with a cle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com