Mobile wine making device

A technology of equipment and mobile vehicles, which is applied in the field of mobile distillation and separation devices, can solve the problems of non-flowing operation, residual mash, affecting wine quality, etc., and achieve the effects of convenient feeding and discharging, avoiding burnt and peculiar smell, and reducing the difficulty of production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

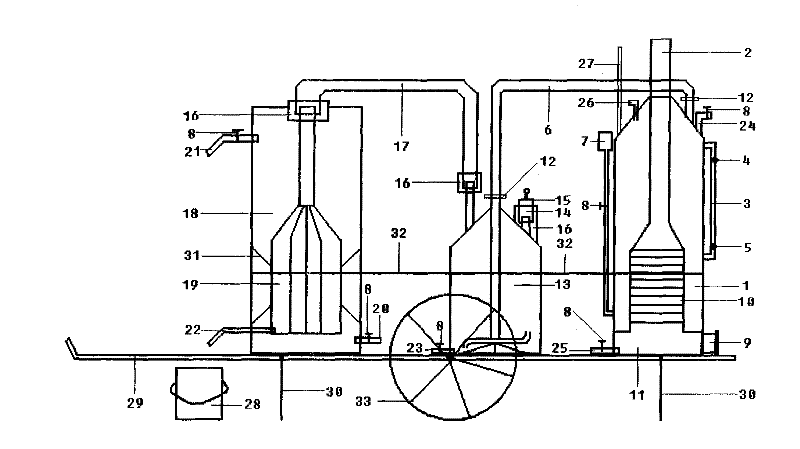

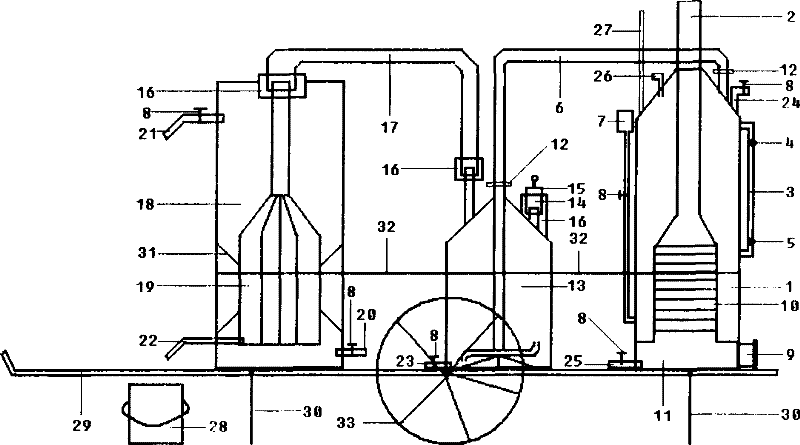

[0008] With reference to the drawings, the present invention includes an atmospheric pressure boiler 1, a barrel 13, a cooler 19, and a cooling pool 18. The boiler 1, a barrel 13 and a cooler 19 form a set through a steam delivery pipe 6, a barrel through the air pipe 17. Distillation and separation device, under the atmospheric pressure boiler 1, there is a heat transfer pipe 10, a smoke pipe 2 is installed on it, and a water level gauge 3, a water tank 7, a boiler safety pipe 27 and an air inlet valve 26 are installed on the upper part of the boiler. 13 is provided with a feeding port 14, a sealing cover 15 and a water seal 16, and a drain pipe 23 is provided at the lower end of the barrel 13 and is set between the boiler (1), the barrel (13) and the cooling pool (18). There is a fixed iron ring (32) for fixing, a mobile car (29) is provided under the distillation separation device, and the distillation separation device is fixed on the mobile car (29). There are a total of 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com