Transformer with high coupling efficiency

A technology for transformers and high-voltage wires, applied in the field of transformers, can solve the problems of large spacers, poor coupling efficiency, and the length of the bobbin body 12 cannot be shortened, and achieve high coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

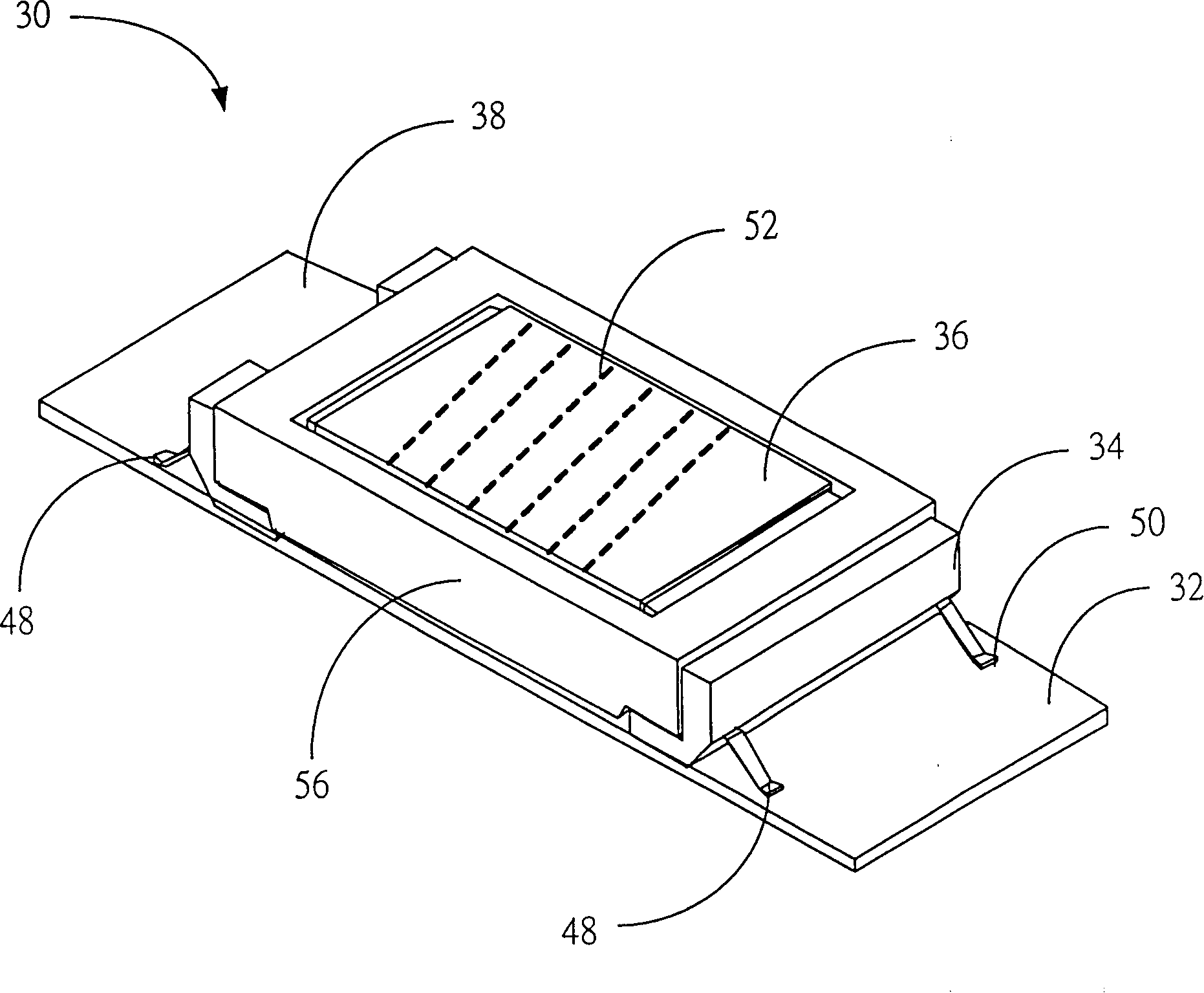

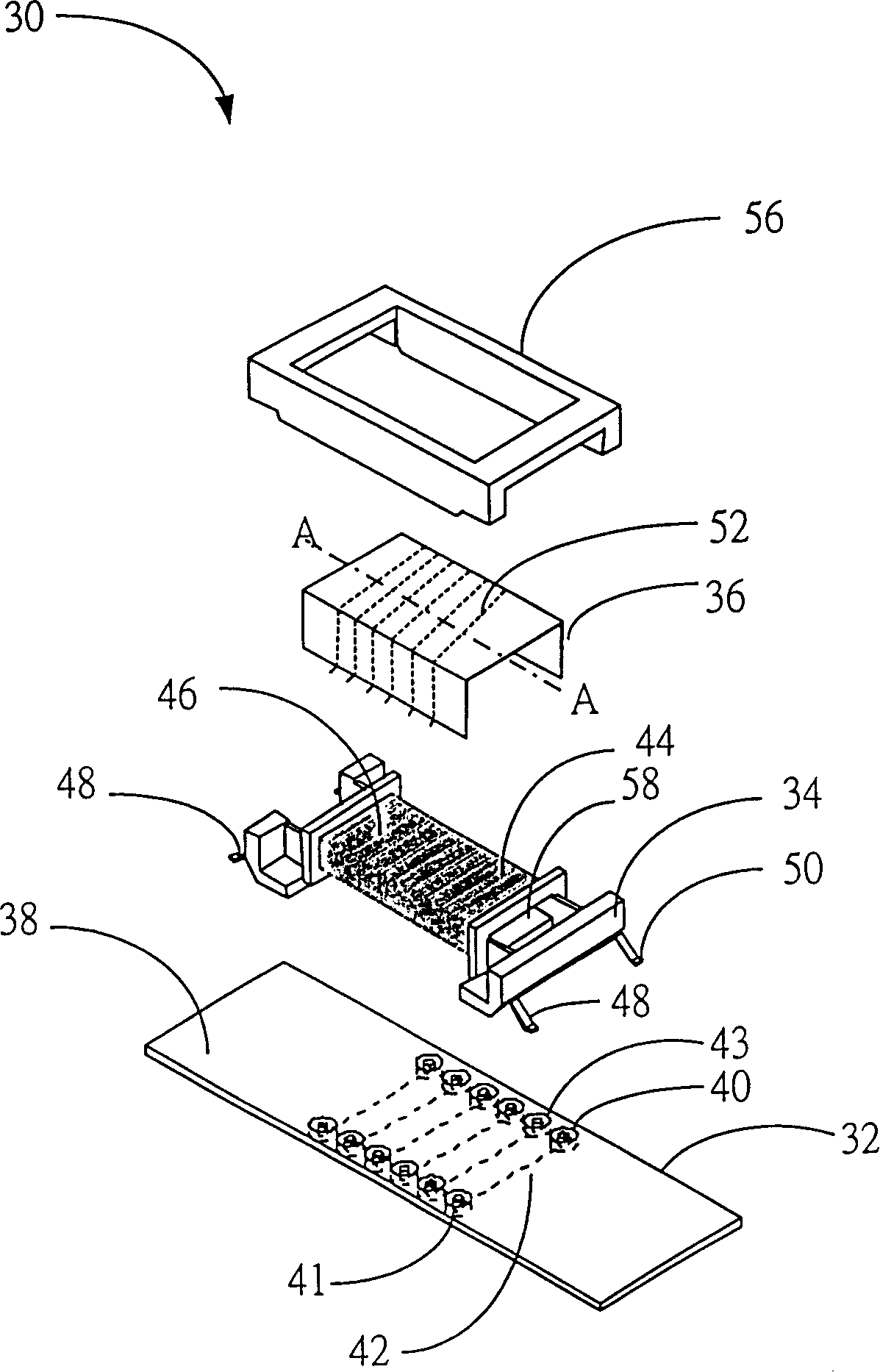

[0014] see figure 2 and image 3 , figure 2 is a schematic diagram of the transformer 30 of the present invention, image 3 for figure 2 A combined element diagram of the transformer 30 is shown. The transformer 30 of the present invention includes a base plate 32 , a bobbin body 34 and a wire device 36 . The substrate 32 can be a single-layer, double-layer or multi-layer printed circuit board (Printing Circuit Board), here take a double-layer printed circuit board as an example, wherein the substrate 32 defines a front 38 and a back 39 (not shown), the substrate 32 It includes a plurality of pads (Pads) 40 and a plurality of lower wires 42 . Each pad 40 is disposed on the substrate 32 and used as an electrical connection point between the front side 38 and the back side 39 of the substrate 32 , wherein each pad 40 may be a copper foil penetrating through the substrate 32 . Each lower wire 42 is disposed on the back surface 39 of the substrate 32 for electrically conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com