Oil slurry charring firing device and its method

A slurry and carbonization technology, which is applied in the petroleum industry, coking carbonaceous materials, coking ovens, etc., can solve problems such as long analysis time, unfavorable catalyst powder research, and large solvent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

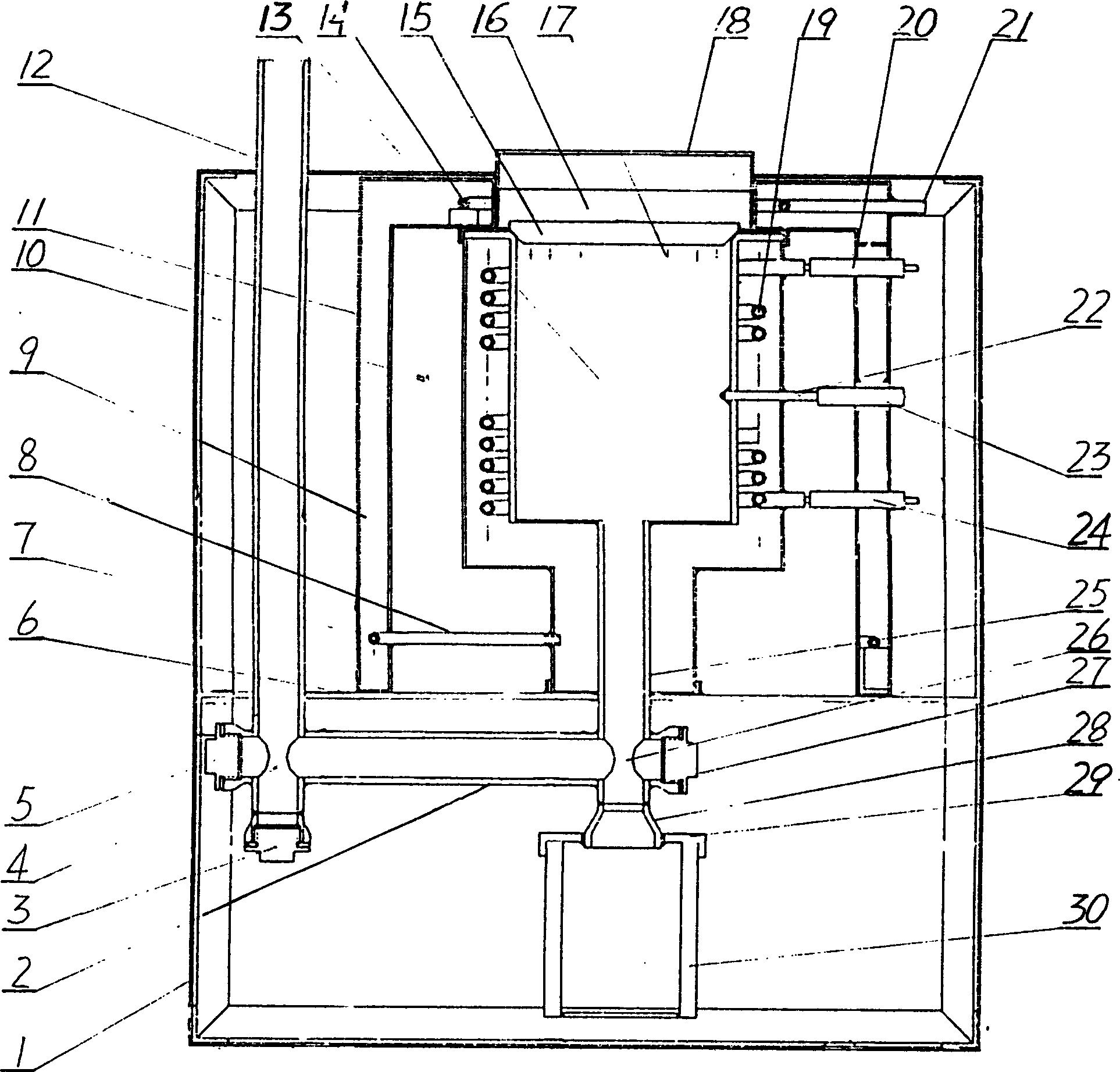

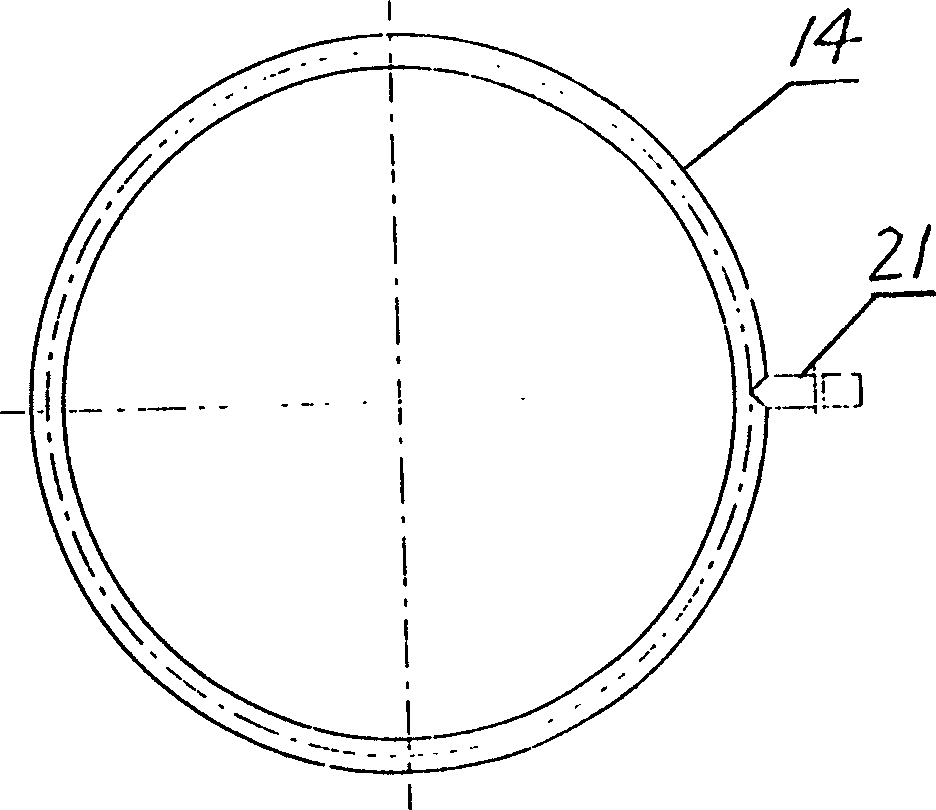

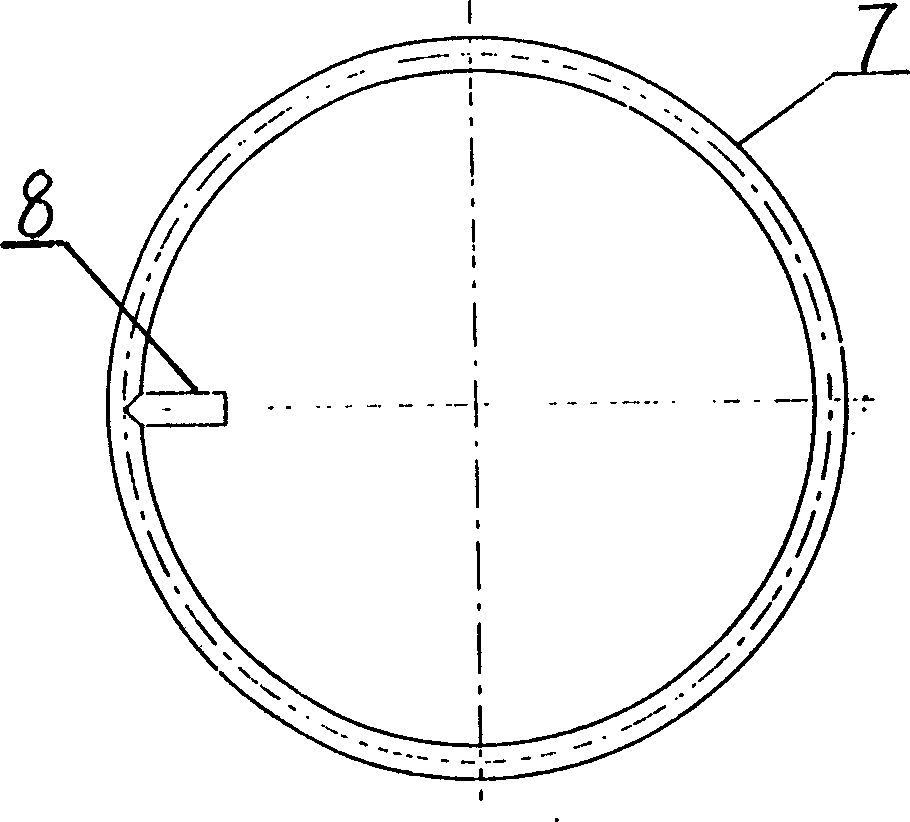

[0012] First look figure 1 , The oil slurry carbonization burning device consists of the chassis 1, the flue pipe 2, 12, 25, the flue plug 3, 5, 27, the cross 4, 26, the partition 6, the gas outlet ring pipe 7, the gas outlet pipe 8, Insulation jacket 9, thermal insulation layer 10, 16, heating jacket 11, sample box 13, air inlet ring tube 14, top plug 15, air outlet 17, top cover 18, heating tube 19, heating tube connector 20, 24, inlet The gas connector 21, the thermocouple 22, the thermocouple connector 23, the cone section tube 28, the cup cap 29, and the cup 30 are composed.

[0013] In the oil slurry carbonization and burning device of the present invention, the chassis 1 can be made of a square frame welded by angle iron and then covered with white iron. It is divided into upper and lower parts by a partition 6. The upper part separated by the partition 6 is mainly a heating furnace. The insulation jacket 9 and the heating jacket 11 are both cylindrical in shape. The insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com