Method for controlling concavo-convex appearance on the working surface when processing round head by milling cutter

A technology of workpiece surface and ball end milling cutter, which is applied in the direction of metal processing machinery parts, metal processing, automatic control devices, etc., can solve the problems that the blade phase difference cannot be set, the circumferential positioning function cannot be set, and the frictional resistance can be reduced. , increase wear resistance, increase the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

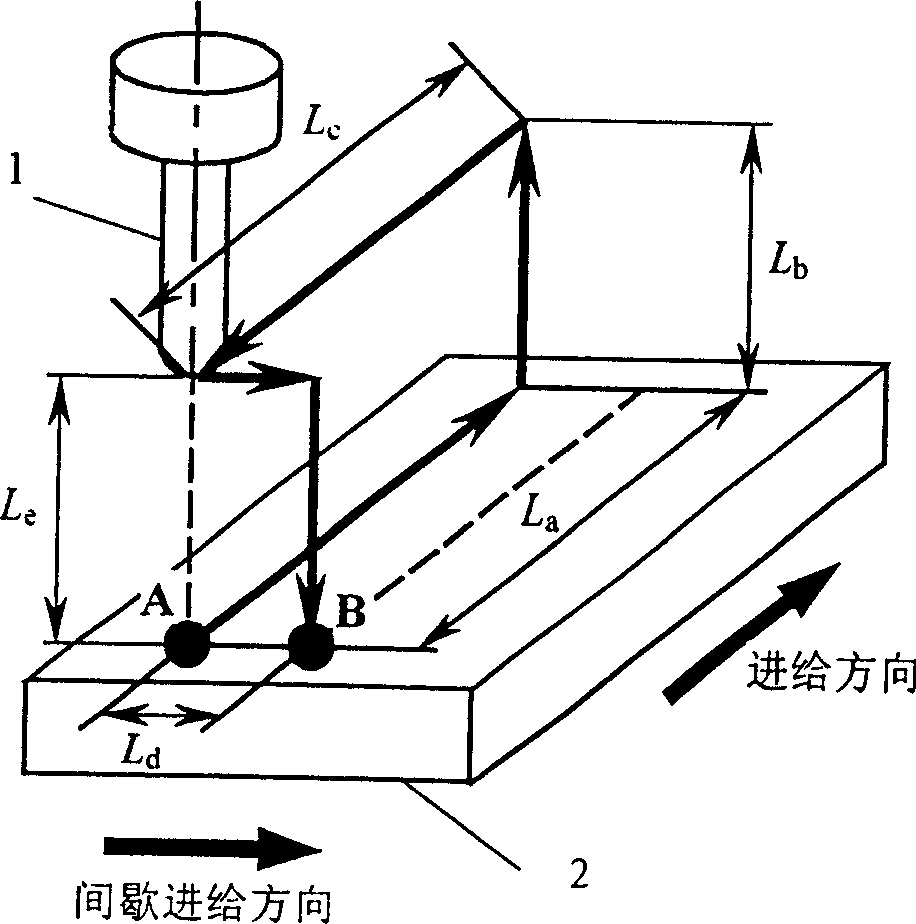

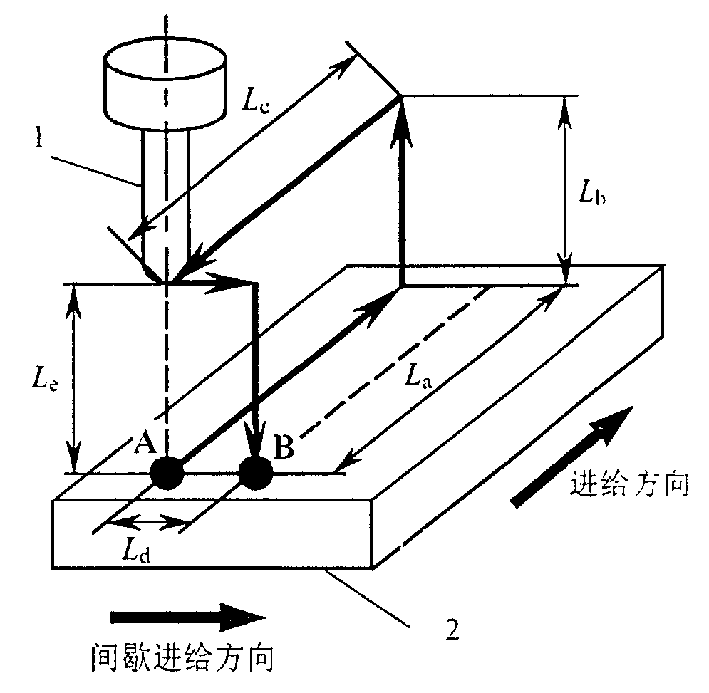

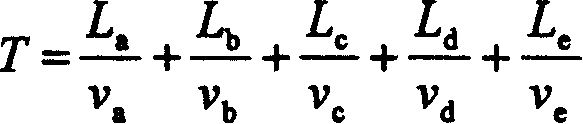

[0018] Such as figure 1 As shown, in actual processing, due to the feeding distance L of the milling cutter 1 a , back distance L c and the feed distance L d is fixed, so only the tool lift distance L b and feed distance L e to adjust the moving distance of the milling cutter, and the lifting distance L b and feed distance L e are equal, that is to say, the desired concave and convex shape can be obtained by adjusting the distance of lifting the knife.

[0019] Material of workpiece 2: brass; material of milling cutter 1: solid carbide, radius of milling cutter 1 is 5 mm; cutting depth of 0.2 mm; spindle speed n=250 rpm; inclination angle of milling cutter 1 is 15°; Feed speed v a =v b =v c =v d =v e = 250 mm / min; L a = L c = 100 mm, L d = 0.5 mm.

[0020] (a) When L b = L e When = 0.750 millimeters, by formula (1)-formula (3), obtain blade phase difference ω=0 °, according to the actual machining result, the pit of machined surface corresponds neatly up and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com