Sol-gel color fixing method

A gel fixing and sol technology, applied in textiles, papermaking, fiber processing, etc., can solve problems such as unrealistic, textiles cannot withstand high temperature roasting, etc., and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

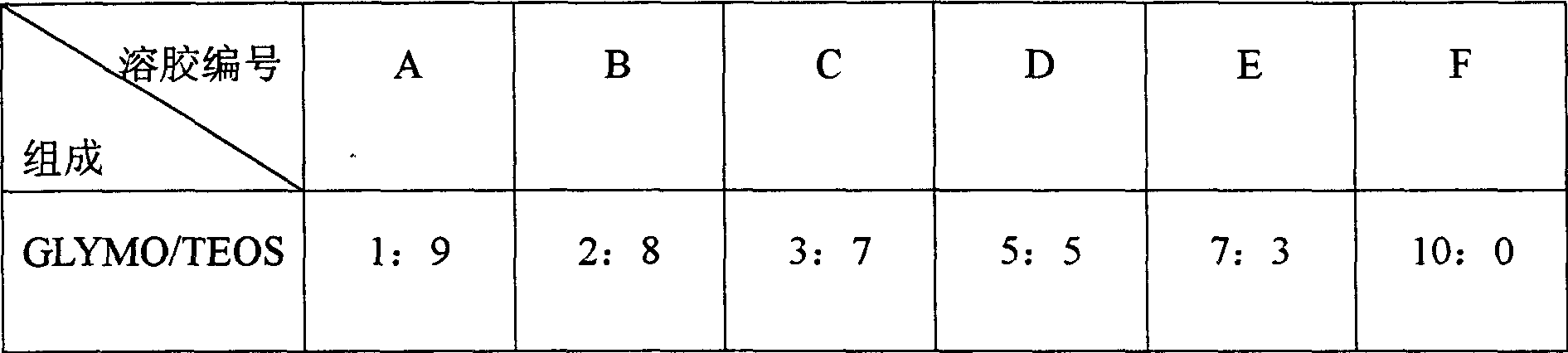

[0030] (1) Add ethyl orthosilicate (0% to 50%), γ-glycidyl etheroxypropyl trimethoxysilane (0.1% to 50%), and ethanol (30% to 90%) to the three necks in sequence. In the bottle, stir on the stirrer to make them mix evenly, and the stirring speed is 200-400 rpm; add the hydrochloric acid (0.005-1.0mol / l) solution into the mixed solution dropwise under stirring; stir at room temperature for 24 Hour.

[0031] (2) Dip and roll the dyed fabric twice in the finishing solution (pressure 2-3kg / cm2) 2 ), and then dried in a blast oven at 100-180°C for several minutes.

[0032] (3) Carry out the fastness test to the dyed fabric, specifically as follows:

[0033] ① Soaping fastness test: Prepare 4g / L soaping liquid, sew a 4cm*10cm cloth sample with white cloth of the same size, soak in 1:50 soap liquid, put it into the soaping fastness tester, After soaping at 40°C for 30 minutes, take it out, wash the cloth sample with distilled water, remove the stitches, and dry it. Then test it o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com