Method for mfg. rotor-stator pair of cycloid device '

A technology of a cycloid device and a manufacturing method, which is applied in the directions of electromechanical devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as difficult processing, difficult quality assurance, and complicated processes, and achieve stable product quality and manufacturing process. Simple, precise fit for the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

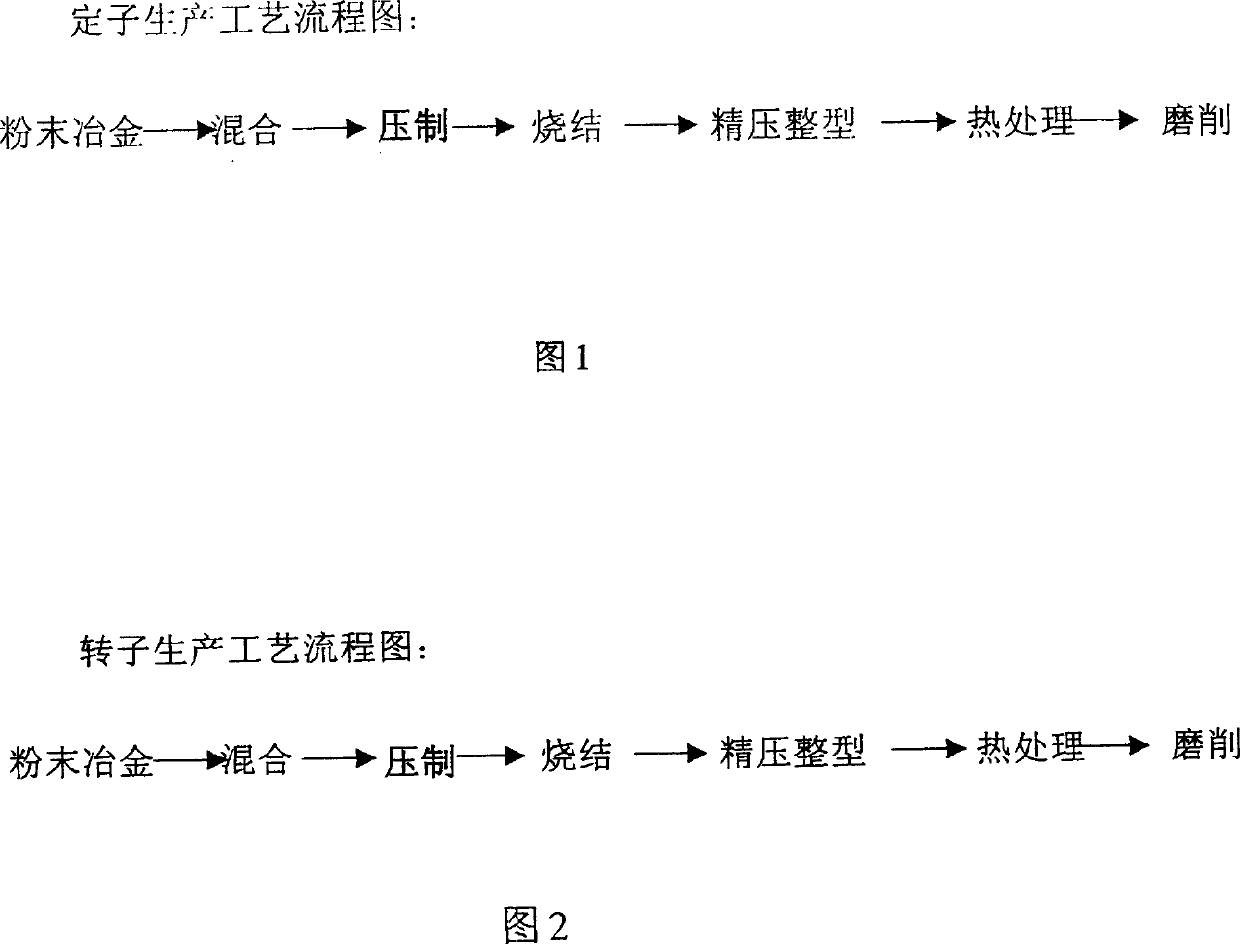

[0026] 1. The processing method of the stator:

[0027] In the present invention, two sets of high-precision powder metallurgy pressing molds are manufactured according to the structure and technical parameters of the stator in the cycloid metering device, one of which is a pressing mold for the stator, and the other is a precision pressing and shaping mold for the stator. The compression mold shaping mold is carried out by conventional methods for making molds. The mold material is made of mold steel and the like. Then choose the pressure-resistant and wear-resistant high-density powder metallurgy material corresponding to the stator in the cycloid metering device, mix the powder metallurgy material evenly, and press the stator on a 500-ton hydraulic press to make the stator. The above-mentioned pressed stator is sintered at a high temperature of 1200 degrees for 30 minutes, and the required performance of the stator is obtained through sintering. The performance of the stat...

Embodiment 2

[0032] 1. The processing method of the stator:

[0033] Using the processing method in Example 1, a high-quality stator can also be produced. Among them, the process technical parameters and process conditions are as follows: after powder metallurgy materials are mixed evenly, the stator is pressed and molded with a stator on an 800-ton hydraulic press; the stator is sintered at a high temperature of 1000 degrees for 30 minutes.

[0034] 2. The processing method of the rotor:

[0035] Using the processing method in Example 1, a high-quality rotor can also be produced. The process technical parameters and process conditions are as follows: After the powder metallurgy materials are mixed evenly, the rotor is pressed and molded into the rotor on an 800-ton hydraulic press; the rotor is sintered at a high temperature of 1200 degrees for about 30 minutes.

[0036] 3. Grinding and grinding the semi-finished products of the rotor and stator above into a rotor and stator pair with a...

Embodiment 3

[0038] 1. The processing method of the stator:

[0039] Using the processing methods in Embodiments 1 and 2 can also be processed into a stator with precise matching accuracy and high wear resistance. The process parameters are selected as follows: press pressure: 1000 tons, high temperature sintering temperature: 1200 degrees, sintering time: 30 minutes.

[0040] 2. The processing method of the rotor

[0041] Using the processing methods in Embodiments 1 and 2 can also be processed into rotors with precise matching accuracy and high wear resistance. The process parameters are selected as follows: press pressure: 1000 tons, high temperature sintering temperature: 1200 degrees, sintering time: 30 minutes.

[0042] In the present invention, the stator and the rotor form a turn, and the stator pair is used as a set. According to the manufacturing process of the present invention, large-displacement rotor and stator pairs can be produced, and the nominal pressure is more than 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com