Soil-less seedling growing and pot-free transplanting method for cotton

A technology of soilless seedling cultivation and cotton, which is applied in the field of soilless seedling cultivation and transplanting of cotton, which can solve the problems of no potless seedling cultivation and transplanting methods of cotton, etc., and achieve accelerated intensive and regional planting and convenient transportation , Realize the effect of industrialization management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

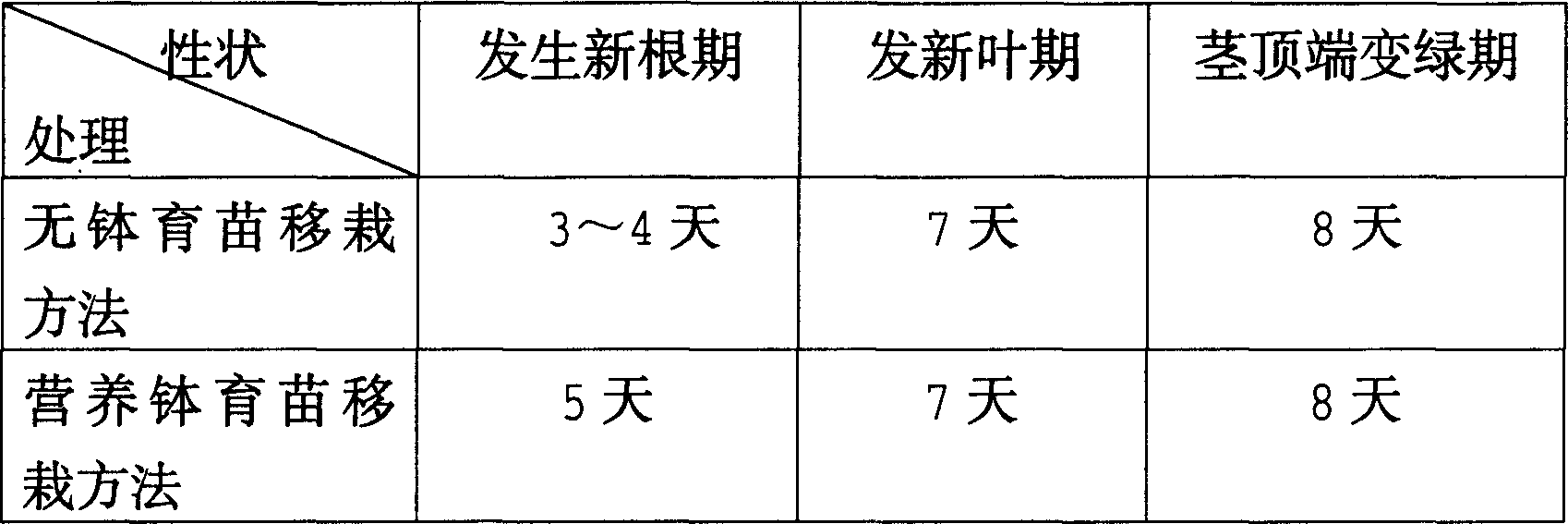

Examples

Embodiment Construction

[0017] When the temperature is stable and exceeds 15°C, such as in Henan, start seedling cultivation in early April. First of all, seedbeds and greenhouse sheds should be established. The size of the greenhouse shed depends on how many seedlings are raised. Due to the thick seed coat and poor water permeability of cottonseeds, the shelling of cotton seedlings must be solved first in potless seedling cultivation. Using sand, coconut powder, vermiculite, etc. or a combination of them as the medium substrate can effectively solve the problem of cotton seedlings. The problem of seedling breaking shell. On the seedbed or the seedling tray in the greenhouse shed, evenly lay the substrate layer based on the above substrate, the thickness of the substrate layer is about 4-6cm. Sow the selected cotton seeds in the sun, so that the germination rate of the seeds can reach more than 95%, and sow them on the seedbed or in the seedling tray, and the seeding rate on the seedbed is 0.4-0.7k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com