Gas auxiliary semi-solid substance shaper

A gas-assisted, semi-solid technology, used in the field of gas-assisted forming devices, can solve the problems of low dimensional accuracy and surface quality, and achieve the effects of improving surface and internal quality, stable and reliable processing dimensions, and reducing sink marks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

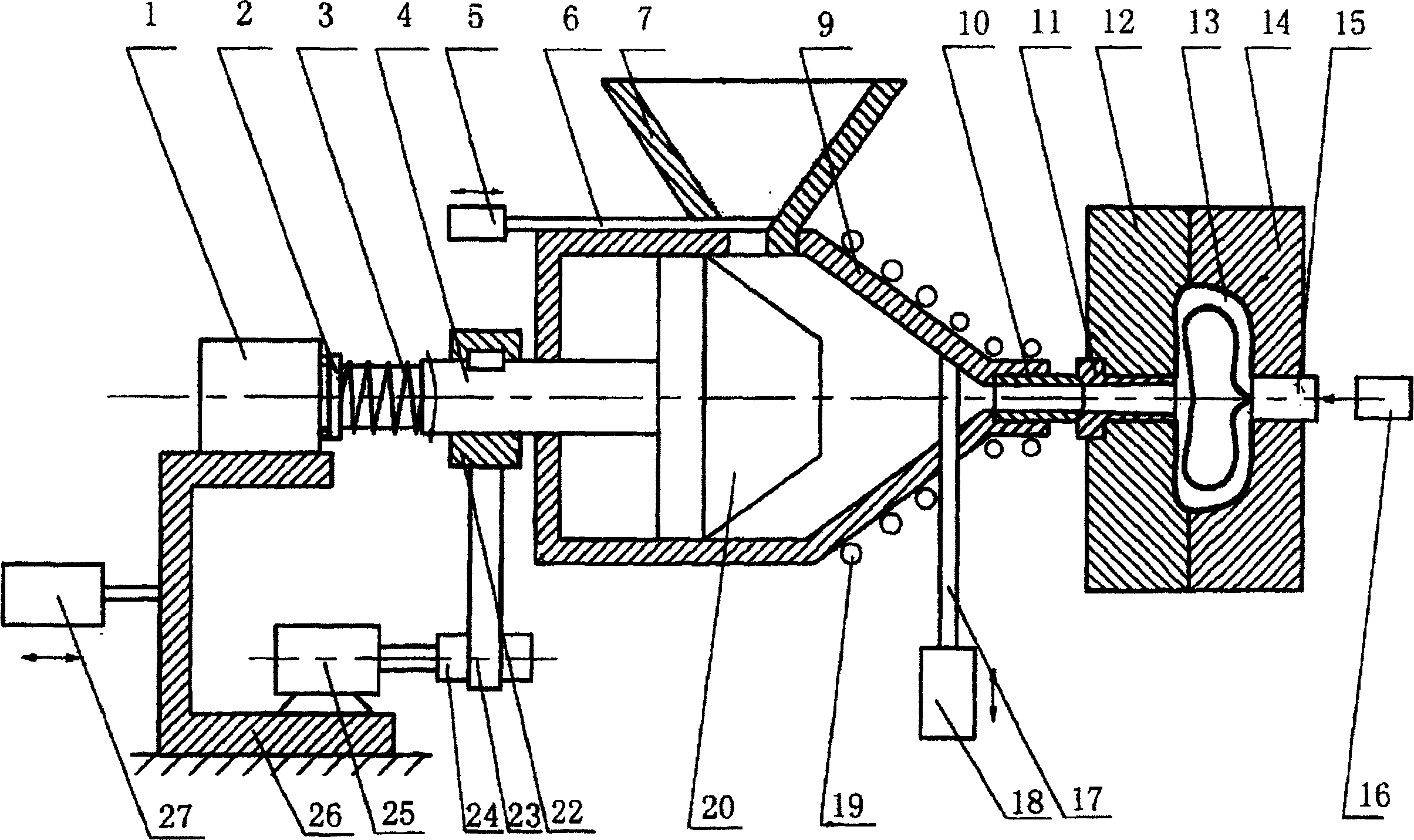

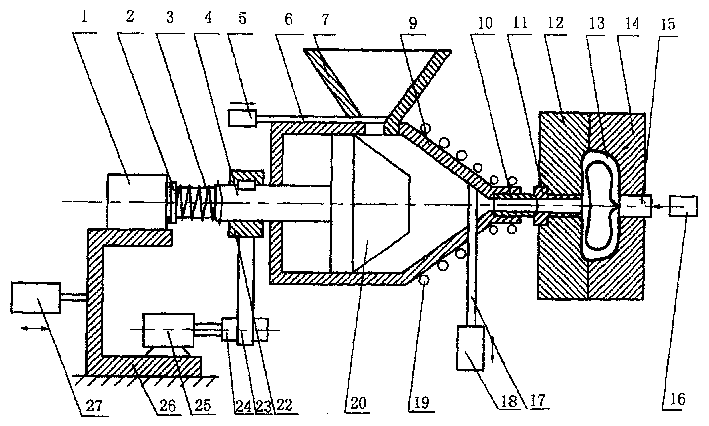

[0009] The present invention includes a heating cylinder 9, a hopper 7 installed on the upper part of the heating cylinder 9, a heating coil 19 wound on the heating cylinder 9, an extruding feeding piston 20 inside the heating cylinder 9, and a rotating shaft connected to the extruding feeding piston. device, feeding piston rod 4, slidable support 26, mould, and it also includes a gas generation controller 16, and one end of the described feeding piston rod 4 is fixed on the described slidable support 26 through the end face bearing 2 and the bearing seat 1 , the other end is fixedly connected with the extruding feeding piston 20; the driver 27 drives the extruding piston 20 through the slidable bracket 26 and the feeding piston rod 4; the heating cylinder 9 passes through the nozzle 10 1. The sprue bushing 11 is connected with the fixed module 12 of the mold; the gas generation controller 16 is connected with the movable module 14 of the mold through the gas injection nozzle 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com