Surface tension driving liquid flow chiplized high-density micro-array liquid transferring equipment

A technology of surface tension and transfer device, which is used in material inspection products, biological testing, etc., can solve the problems of a lot of time for cleaning and drying the needle tip, the uniformity of the sample points that are easily damaged by the needle tip, and the small number of sampling needles. Low cost, low equipment cost, good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

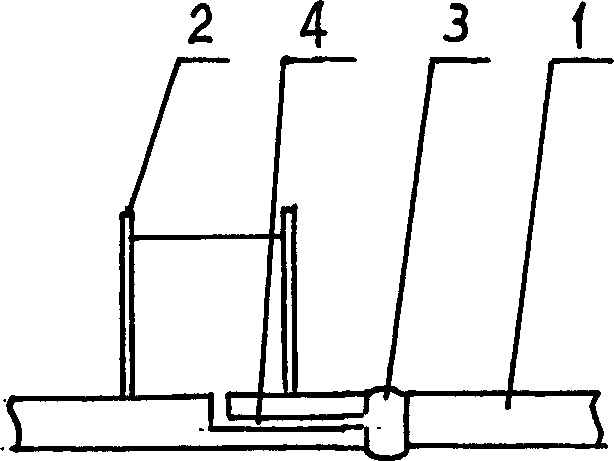

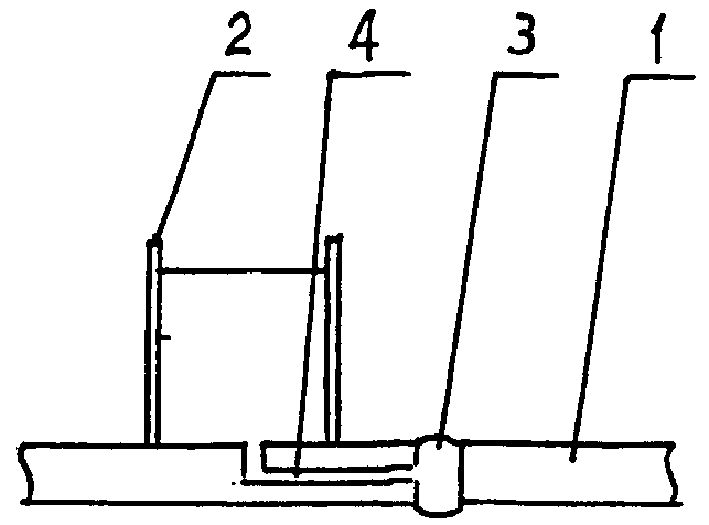

[0024] Such as figure 1 As shown, a metal sheet is selected as the sheet-shaped carrier 1 of the present invention, and its size is selected as 100 mm in length, 40 mm in width, and 1 mm in thickness. A circular liquid storage pool 2 is set on the upper surface of the glass sheet by photolithography technology, its radius is 0.3 mm, and its height is 0.8 mm; a cylindrical liquid transfer head 3 is set beside the liquid storage pool 2, and the radius of the liquid transfer head 3 is 0.05 mm. mm. The liquid storage pool 2 and the liquid transfer head 3 are designed in a paired array, and the distance between adjacent liquid storage pools can be set to 0.4 mm. A long and narrow closed microchannel 4 is connected between the liquid reservoir 2 and the upper port of the liquid transfer head 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com