Means for controlling target erosion and sputtering in magnetron

A magnetron and magnet device technology, applied in sputtering coating, discharge tube, ion implantation coating, etc., can solve the problems of weakening magnetic field strength, electron loss, plasma instability, etc., to eliminate uneven consumption, cost and maintenance time reduction, less prevention and maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described with reference to particular embodiments and certain drawings but the invention is not limited thereto but only by the claims. The drawings described are only schematic and not restrictive.

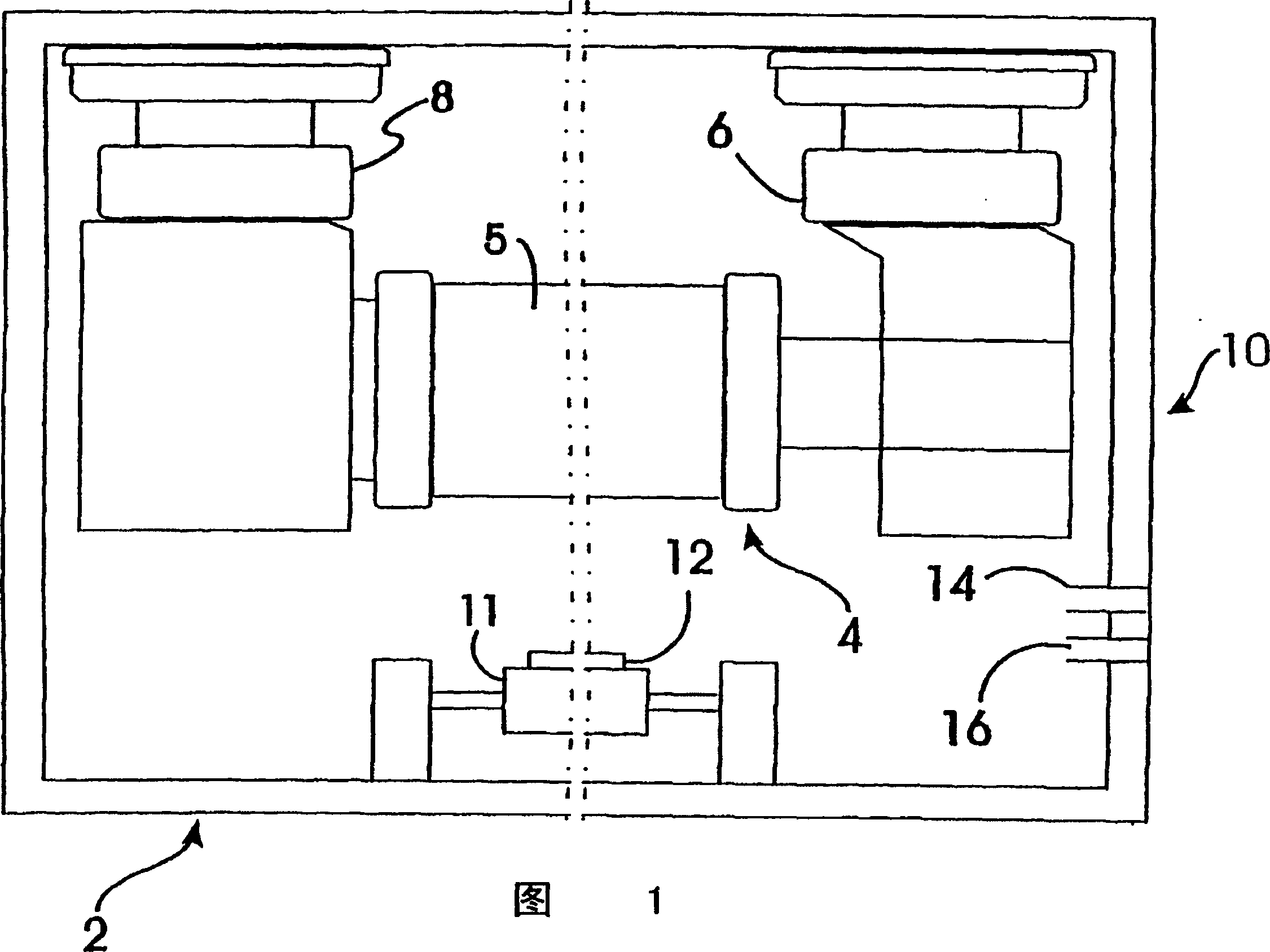

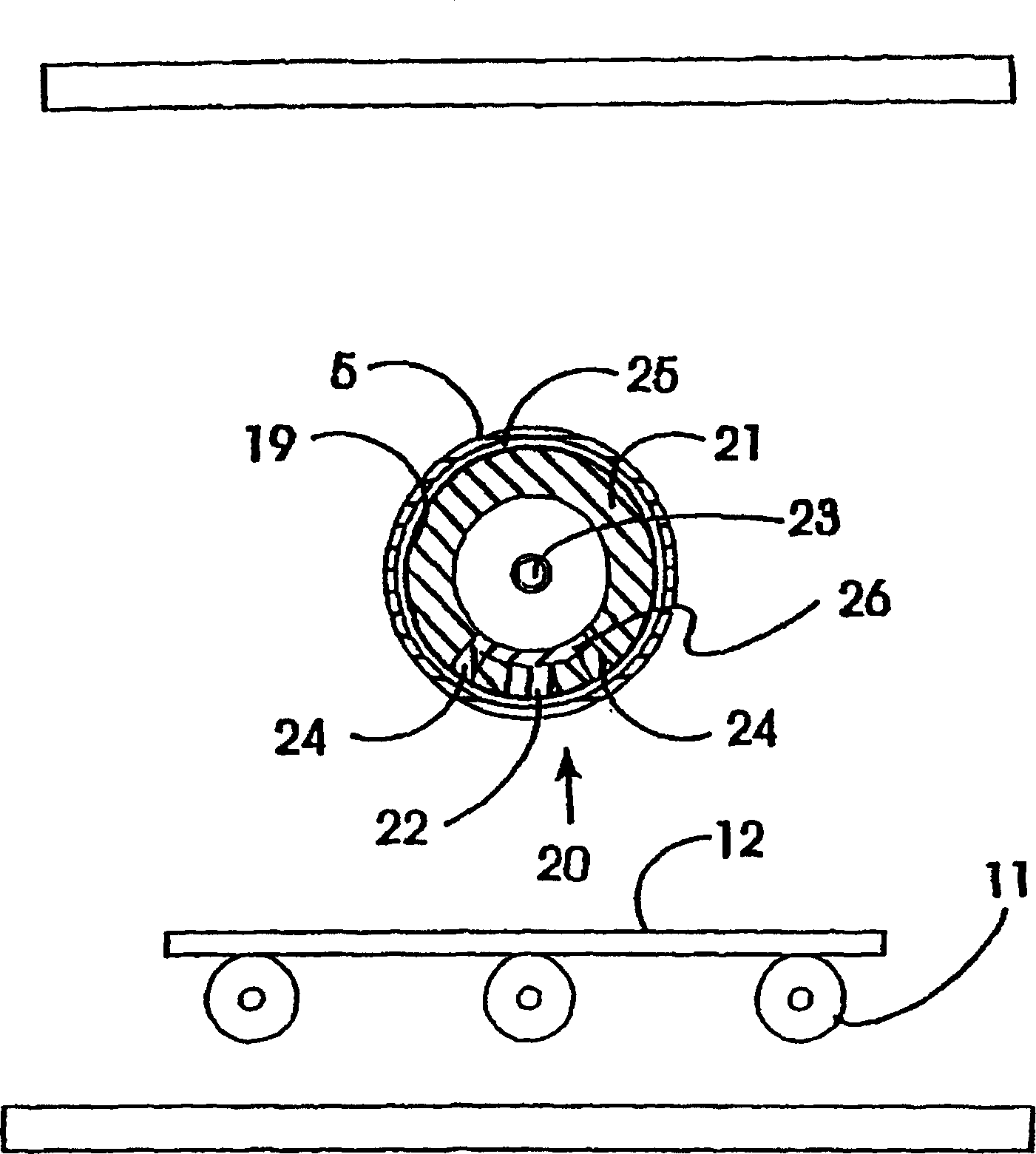

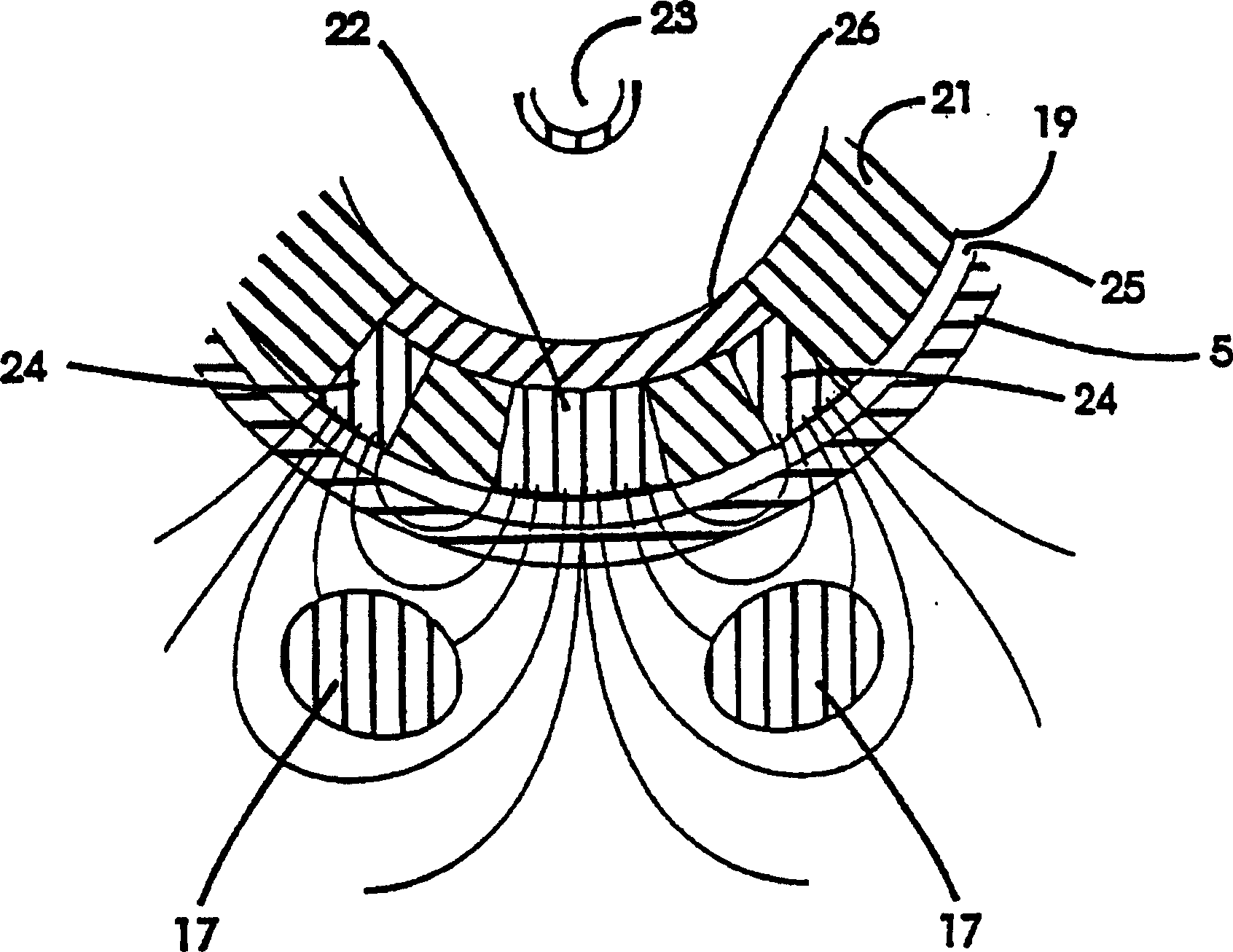

[0037] Figures 1, 2a and 2b are schematic illustrations of a sputtering magnetron 10 according to the present invention. Figure 1 is a side view of a target 4 in a vacuum chamber 2, while Figure 2a is a cross-sectional view through target 4. Figure 2b From Figure 2a Partial enlarged view of target 4. The vacuum chamber 2 preferably includes a movable, cylindrical rotating target 4 . The target 4 can be connected to the target 4 through a feeder 6 by any suitable driving means, for example, an electric motor or a hydraulic press or the like. The other end of the target 4 is supported by another feeder 8 for cooling liquid and power supply (not shown) of the target 4 into the vacuum chamber 2 . The target 4 may be a tube consisting of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com