Cooking fume purifying method

A technology for oil fume purification and kitchen, which is applied to chemical instruments and methods, oil fume removal, separation methods, etc. It can solve problems such as difficulty in purifying oil fume, non-continuous use, and short service life, and achieves simple structure, good purification effect, and long service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

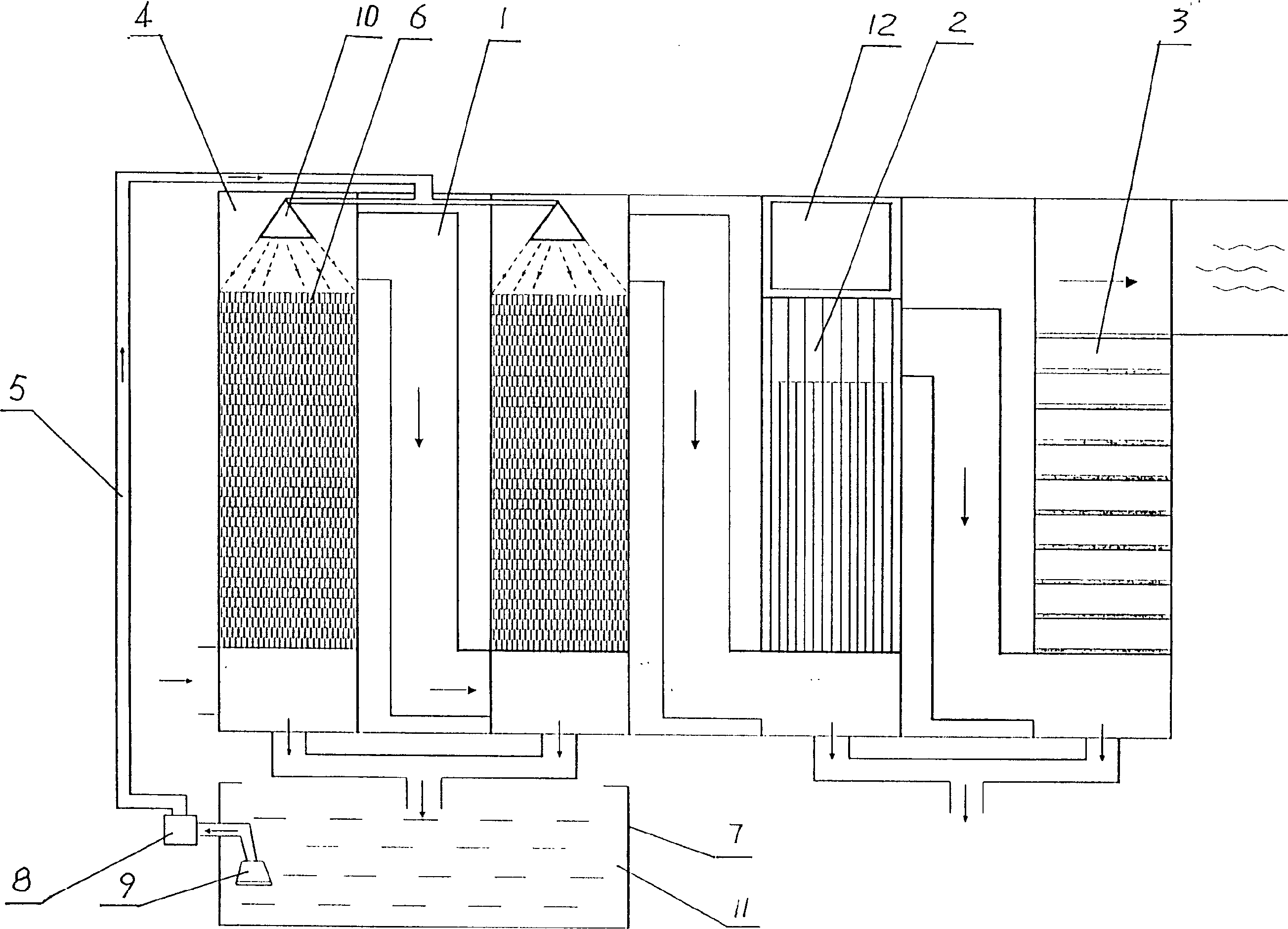

[0012] The present invention includes a cleaning tower 1, the outlet of the cleaning tower 1 is connected to an electric dust removal tower 2, and the outlet of the electric dust removal tower 2 is connected with an activated carbon absorption tower 3. The oil fume enters from the air inlet of the cleaning tower 1, is fully washed by the degreasing cleaning liquid in the cleaning tower 1, enters the electrostatic precipitator 2 for dust removal, and then is absorbed by the activated carbon absorption tower 3 to purify the oil fume.

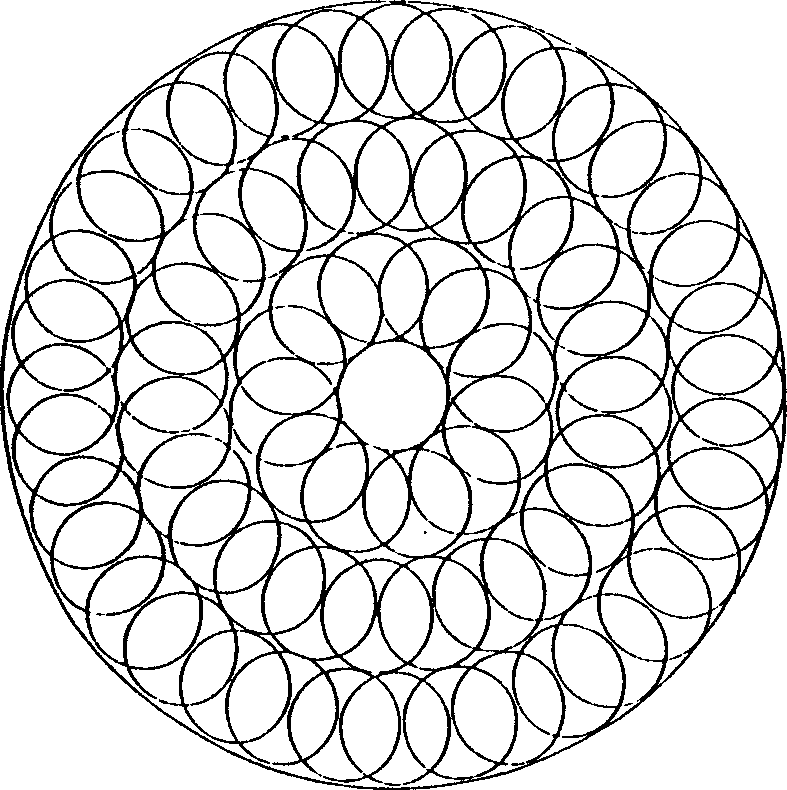

[0013] The cleaning tower 1 is composed of a tower body 4 and a circulating water device 5. There are multiple layers of staggered ceramic rings 6 arranged in the tower body 4. The cleaning tower 1 can be one or more connected in series. The circulating water device 5 includes a circulating water liquid medicine pool 7, a water pump 8, a control valve 9, a shower head 10, and the cleaning liquid medicine 11 in the circulating water liquid medicine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com