Synthesis method of methylhydro cyclo siloxane

A technology of methylhydrogencyclosiloxane and silanes, applied in the field of preparation of methylhydrogencyclosiloxane, can solve problems such as insecurity, and achieve the effects of less methanol consumption, high yield and high equilibrium concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1 A method for preparing methylhydrocyclosiloxane with a high yield of tetramethylcyclotetrasiloxane, comprising silanes with the general formula RR'SiXX and alkanes in a volume ratio of 25-35 parts: 50 The ratio of -70 parts is mixed, gradually dropped into the mixed multiphase mixed solvent system, and stirred, and the hydrolysis reaction is carried out. The volume ratio of the multiphase mixed solvent is composed of alkane: alcohol: water=50-70 parts: 10 -15 parts: 20-36 parts, reaction time: 2-8 hours, reaction temperature: 0-30°C, to obtain methylhydrocyclosiloxane products containing tetramethylcyclotetrasiloxane and linear siloxane By-products, in the general formula RR'SiXX, R=C 1 --C 5 , preferably R=CH 3 ; R'=H, C 1 -C 5 , preferably R'=H; X=Cl, Br, I, OMe, OEt, preferably X=Cl.

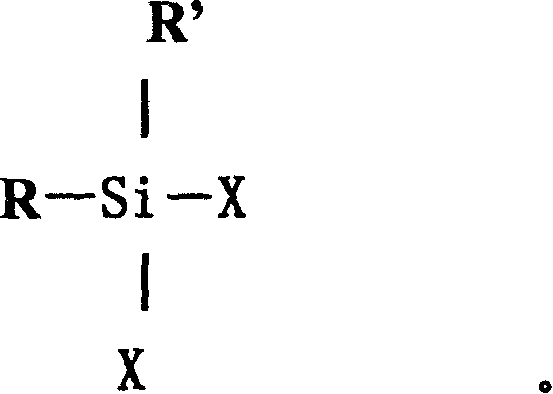

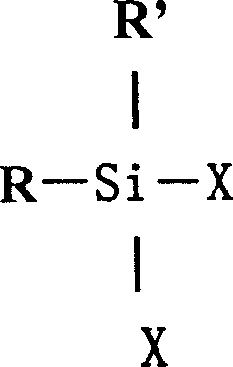

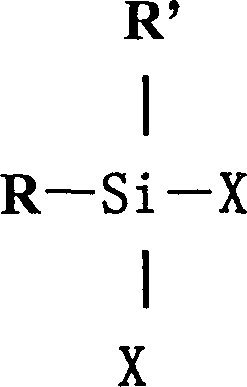

[0022] The structural formula of RR'SiXX is

[0023]

Embodiment 2

[0024] Embodiment 2: The silane material of RR'SiXX general formula is methyl dichlorosilane. All the other are with embodiment 1.

Embodiment 3

[0025] Embodiment 3: The volume ratio composition of the mixed solvent is, alkane: alcohol: water=60-65 parts: 10-12 parts: 20-25 parts. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com