Collecting device

A collection device and collector technology, applied in fluid pressure actuation devices, separation methods, liquid variable volume machines, etc., can solve problems such as low collection efficiency, low collection efficiency, and clogging of filling layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] A collecting device according to an embodiment of the present invention will be described below with reference to the accompanying drawings. The same or corresponding parts are denoted by the same or corresponding reference numerals throughout the drawings.

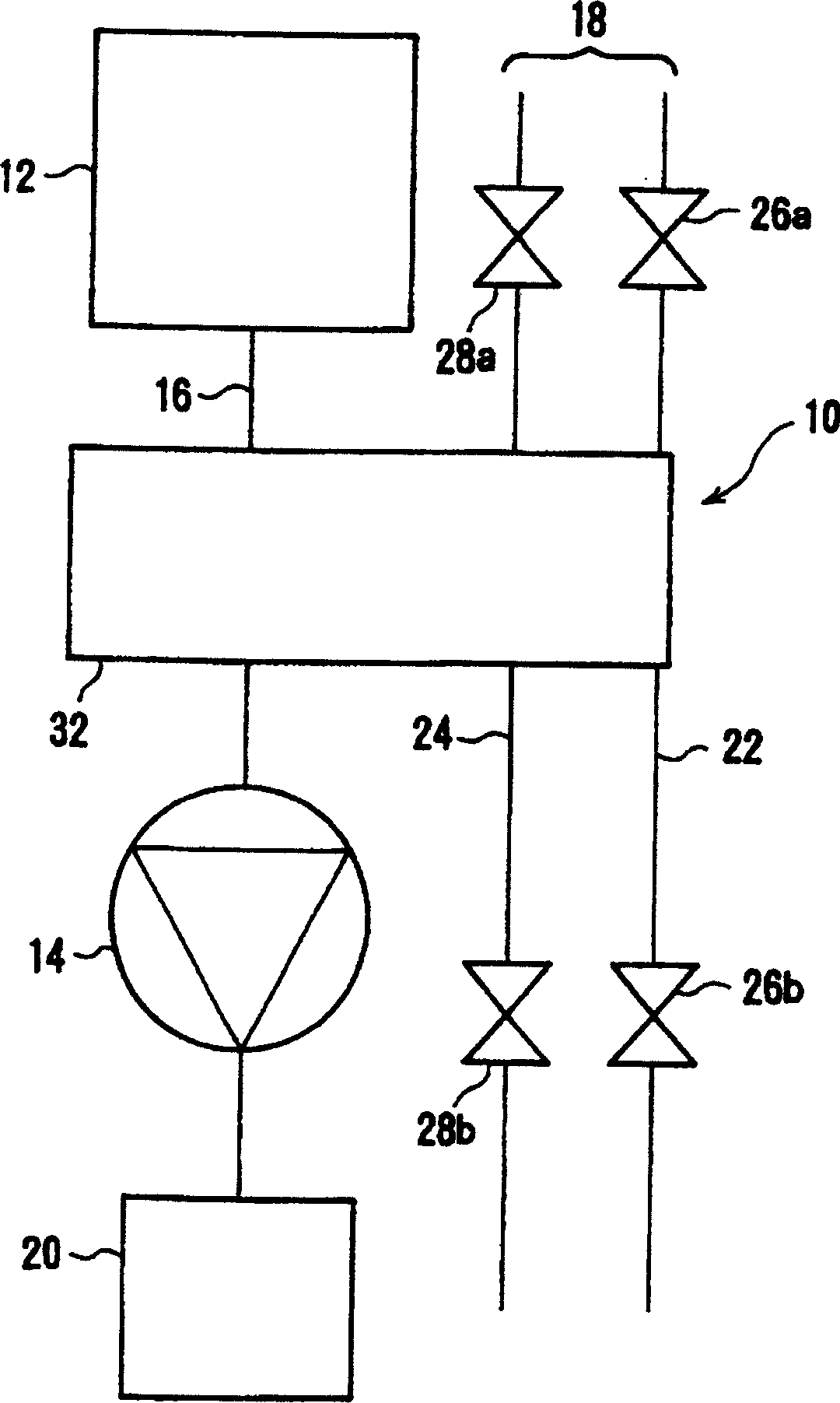

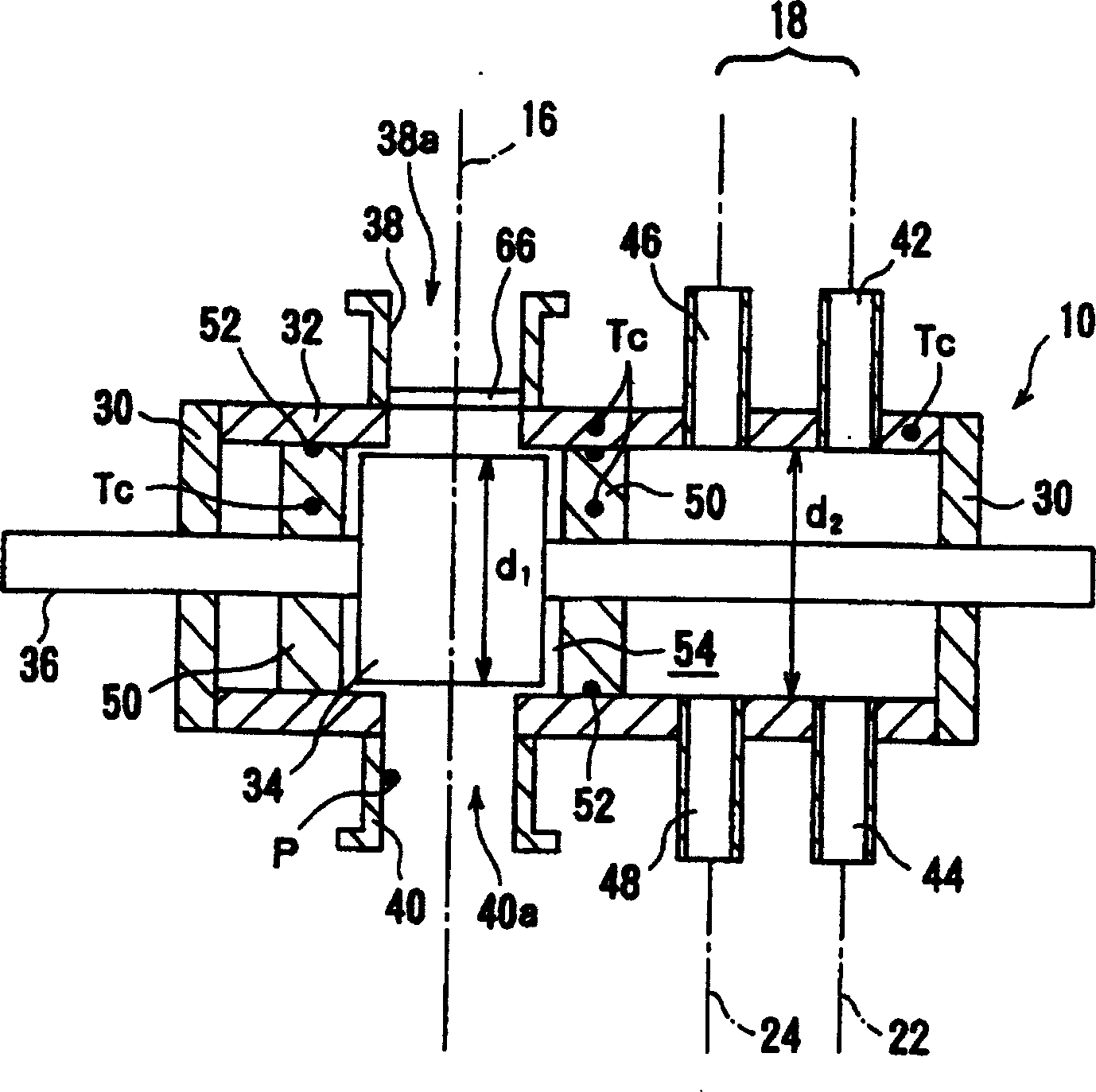

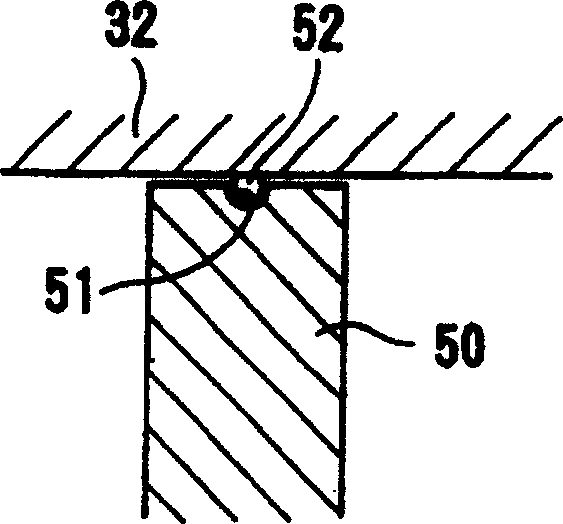

[0052] Figures 1 to 3 A collection device representing a first embodiment of the present invention. The collection device 10 crosses and extends through the exhaust channel 16 and the regeneration channel 18 so that the airtight sealed chamber 12 can be evacuated by the vacuum pump 14 , and the regeneration channel 18 is disposed adjacent to the exhaust channel 16 . In this embodiment, vacuum pump 14 is a single stage vacuum pump. On the other hand, multi-stage vacuum pumps can also be used. An exhaust treatment device 20 that removes toxic substances from exhaust gas is provided downstream of the vacuum pump 14 . The regeneration channel 18 has a line 22 for cleaning liquid and a line 24 for drying gas. In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com