System and method for reducing welding program error for IC welding machine

A welding procedure, integrated circuit technology, applied in the direction of circuit, program control, welding equipment, etc., can solve the problem of time-consuming and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

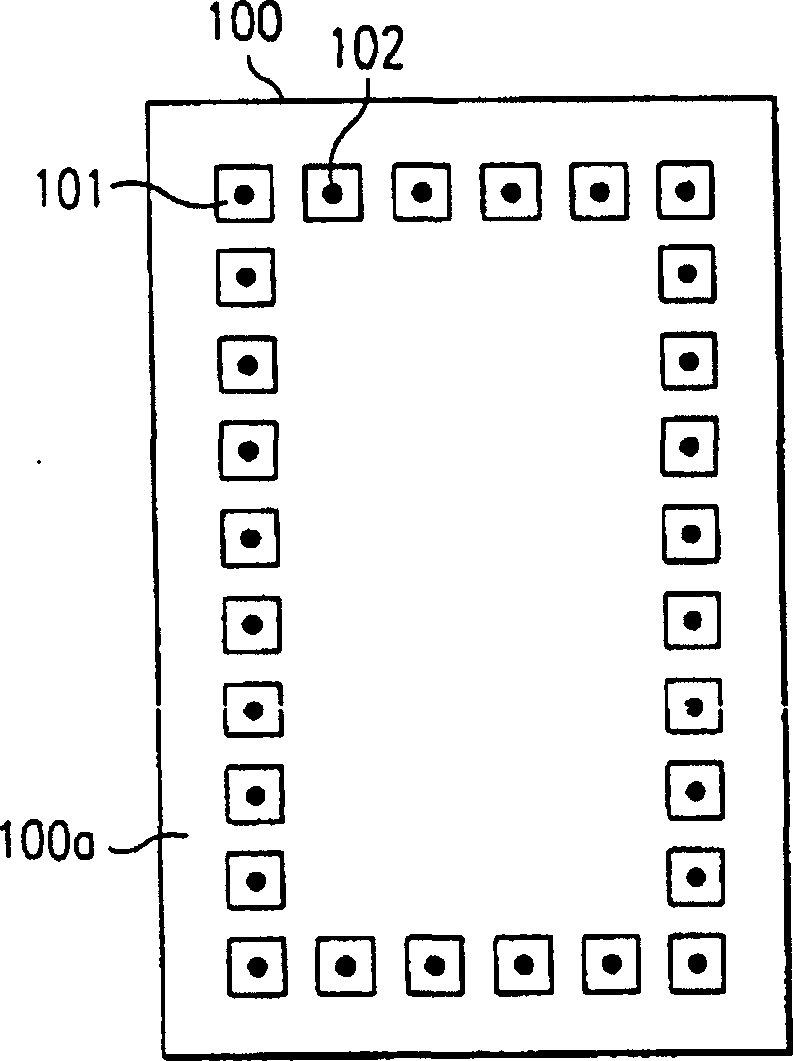

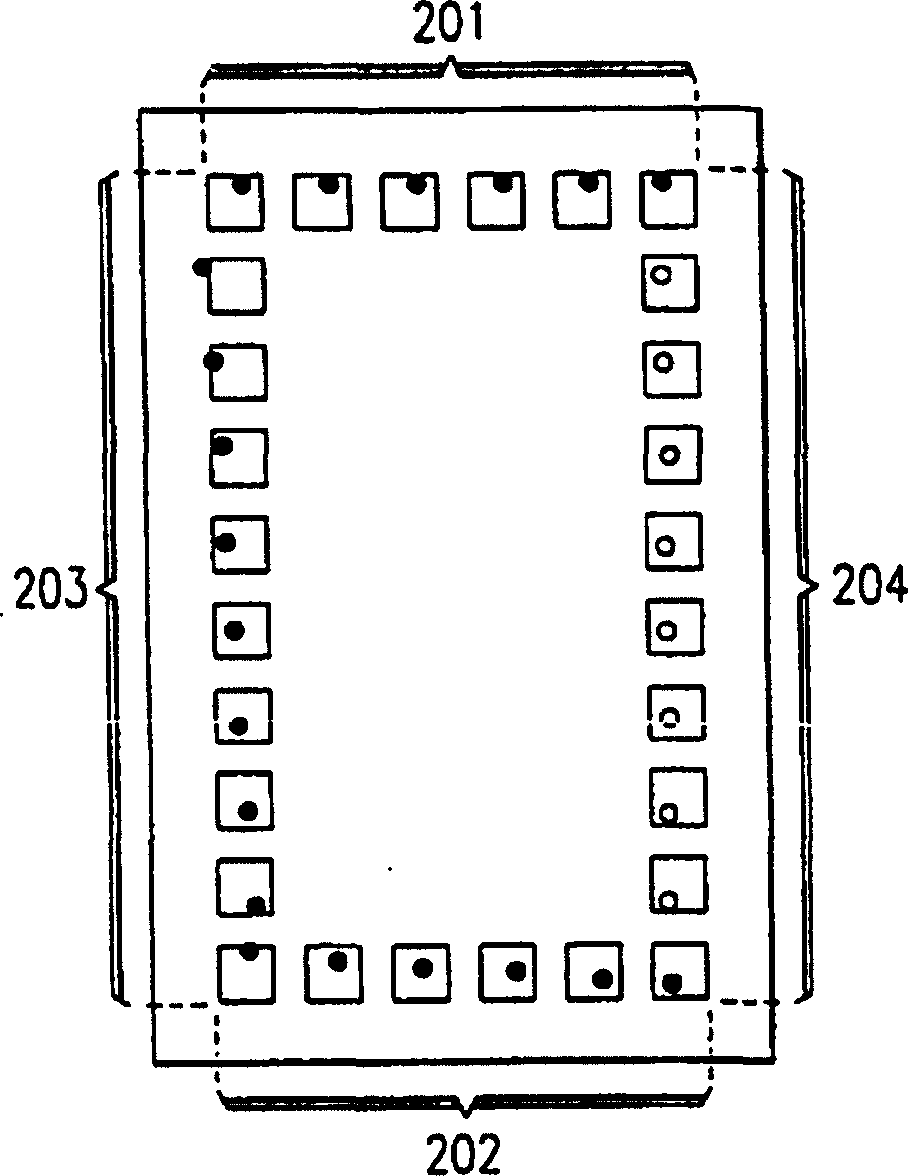

[0042] figure 1 and 2 Examples illustrate the problems and errors that the present invention solves in semiconductor chip assembly and bonding operations. figure 1 In this example, a plurality of bonding pads 101 are placed on the active surface 100 a of the chip 100 . In the ideal assembly situation shown, all of the adhesive 102 attached to the pad 101 is located in the center of the pad area. figure 2 , similar pads are shown, but the adhesive deviates from the ideal position in several ways. In the top row of pads 201, all adhesive is biased towards the perimeter of the pads (here representing a risk to the quality of the soldering and the reliability of the material surrounding the pad area). In the bottom row 202 of pads, the adhesive gradually slopes (some of which will be outside the range of acceptable soldering). In the left column 203 of pads, the adhesive also slopes gradually (so that some of the adhesive comes off the pads). In the right column of pads 204,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com