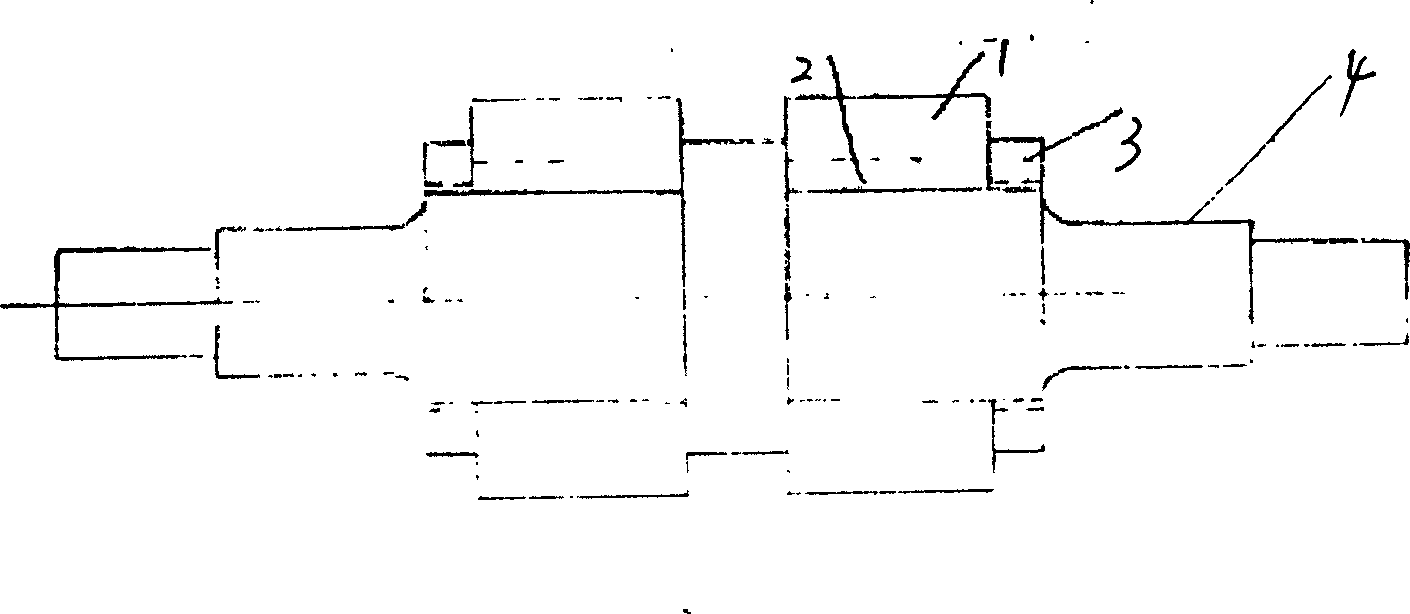

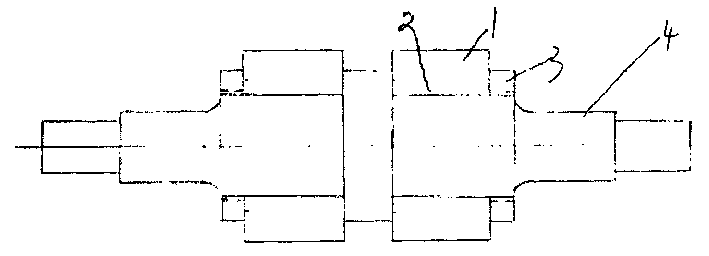

Composite roll ring of high-speed steel

A technology of high-speed steel and composite rolls, which is applied in the direction of rolls, metal processing equipment, metal rolling, etc., can solve the problems of reduced hardness and wear resistance, high manufacturing costs, and difficulty in meeting rolling conditions, so as to improve hardness and durability. Abrasiveness, improved mill operating rate, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Using the chemical composition range of the high-speed steel composite roller ring of the present invention and the preparation method of the prior art, three batches of roller rings with steel grades A, B and C were trial-manufactured. The chemical compositions of the outer layer molten steel and the core molten iron of the three batches of roll rings of the present invention are shown in Table 1. First, the molten steel in the outer layer of the roller ring and the molten iron in the core are respectively smelted in two electric furnaces. The molten steel in the outer layer of the roller ring is treated with rare earth modification. 0.35%, 0.2%, pour the modified outer layer molten steel into the centrifuge mold with a certain rotation speed, the pouring temperature of A, B, C outer layer molten steel is 1420℃, 1470℃, 1530℃ respectively, A , B, and C were cast at temperatures of 120°C, 170°C, and 230°C, respectively, and the coating thicknesses of A, B, and C were 4.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com