Preparation method of antioxidation antifriction lubricating oil additive

A technology of additives and acid catalysts, applied in the directions of additives, lubricating compositions, petroleum industry, etc., can solve the problems of oil oxidation stability and oil anti-wear performance cannot be guaranteed, dosage restrictions, etc., to improve oxidation stability and resistance Grinding, good compatibility, easy to dissolve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Preparation of 2-mercapto-5-tert-dodecyldithio 1, 3, 4 thiadiazole

[0018] According to the conventional method, 2,5 dimercapto 1,3,4 thiadiazole (DMTD) was prepared. Add 12 grams of sodium hydroxide, 20 grams of water and 15 grams of 50% hydrazine hydrate into a 100 ml three-necked flask, stir to dissolve the sodium hydroxide, add 28.5 grams of carbon disulfide, heat to 46 ° C, maintain the temperature for 1.5 hours, and then heat up to 80°C and reacted for 2 hours to obtain 64.5 g of a yellow-green solution, which was transferred to a 500 ml three-neck flask and acidified by adding 48 ml of hydrochloric acid to produce a white solid, namely DMTD.

[0019] Add 30 grams of tertiary dodecyl mercaptan and 100 milliliters of ethanol to DMTD, add 20 grams of hydrogen peroxide dropwise at 40°C, after 1 hour of dropping, the temperature rises to the reflux temperature, react for 2 hours, add solvent gasoline to extract Lift, transfer to 250 milliliters of separat...

Embodiment 2

[0020] Example 2: Preparation of 2-mercapto-5-n-octyldithio-1, 3, 4 thiadiazole

[0021] Referring to the method of Example 1, the tert-dodecylmercaptan in Example 1 is replaced with n-octylmercaptan to prepare 2-mercapto-5-n-octyldithio-1,3,4thiadiazole, and obtain 41 g of a viscous liquid product, 2-mercapto-5-n-octyldithio-1,3,4thiadiazole, has a sulfur content of 42.8% and a theoretical sulfur content of 43.2%.

Embodiment 3

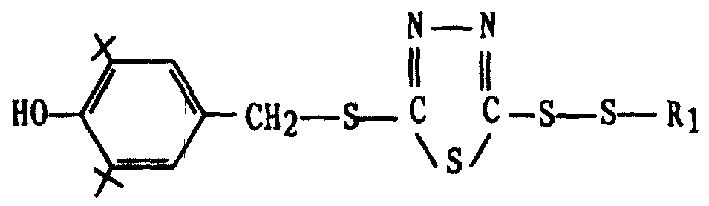

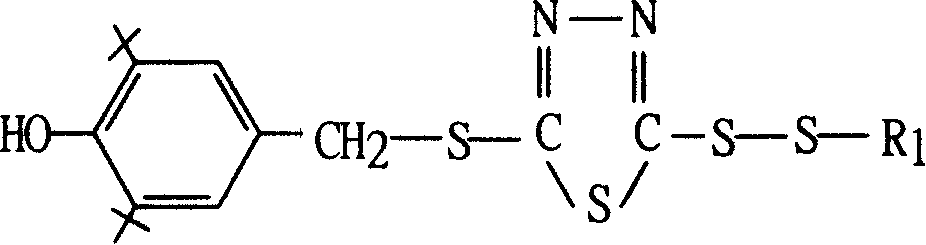

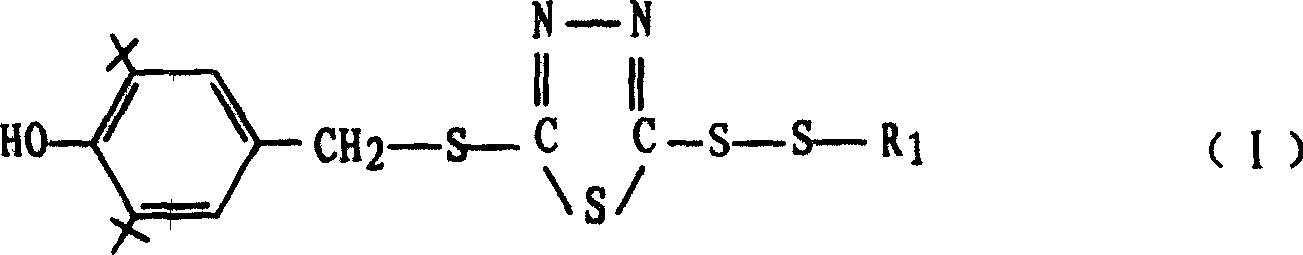

[0022] Example 3: Preparation of 2-(3,5-di-tert-butyl-4-hydroxybenzyl)thio-5-tert-dodecyldithio 1,3,4 thiadiazole

[0023] Weigh 24.7 grams (0.12mol) of 2,6-di-tert-butylphenol, 4.2 grams (0.14mol) of paraformaldehyde, 42.2 grams (0.12mol) of the product of Example 1 and 0.3 grams of p-toluenesulfonic acid, respectively add 250ml three ports In the reaction bottle, the reaction bottle is equipped with a stirring and a condenser, stirring and heating to 110 ° C, and reacting for 6 hours. After the reaction, add 10 ml of 10% sodium bicarbonate aqueous solution to neutralize, then add 60 ml of solvent gasoline and 50 ml of water to extract the reaction Product, then transfer the extraction reaction product to a 500ml separatory funnel, wash with 50ml water each time, static layering, separate the water layer, repeat the second washing until the water layer is neutral. Washed solution is transferred in the 250ml distillation bottle, carries out normal, vacuum distillation, removes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com