Boric acid ester brake fluid and its preparing process

A technology of brake fluid and boric acid ester, which is applied in the petroleum industry, base materials, lubricating compositions, etc., can solve the problems of high cost, instability of esterification and hydrolysis, etc., and achieve product cost reduction, good anti-corrosion effect, tons The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

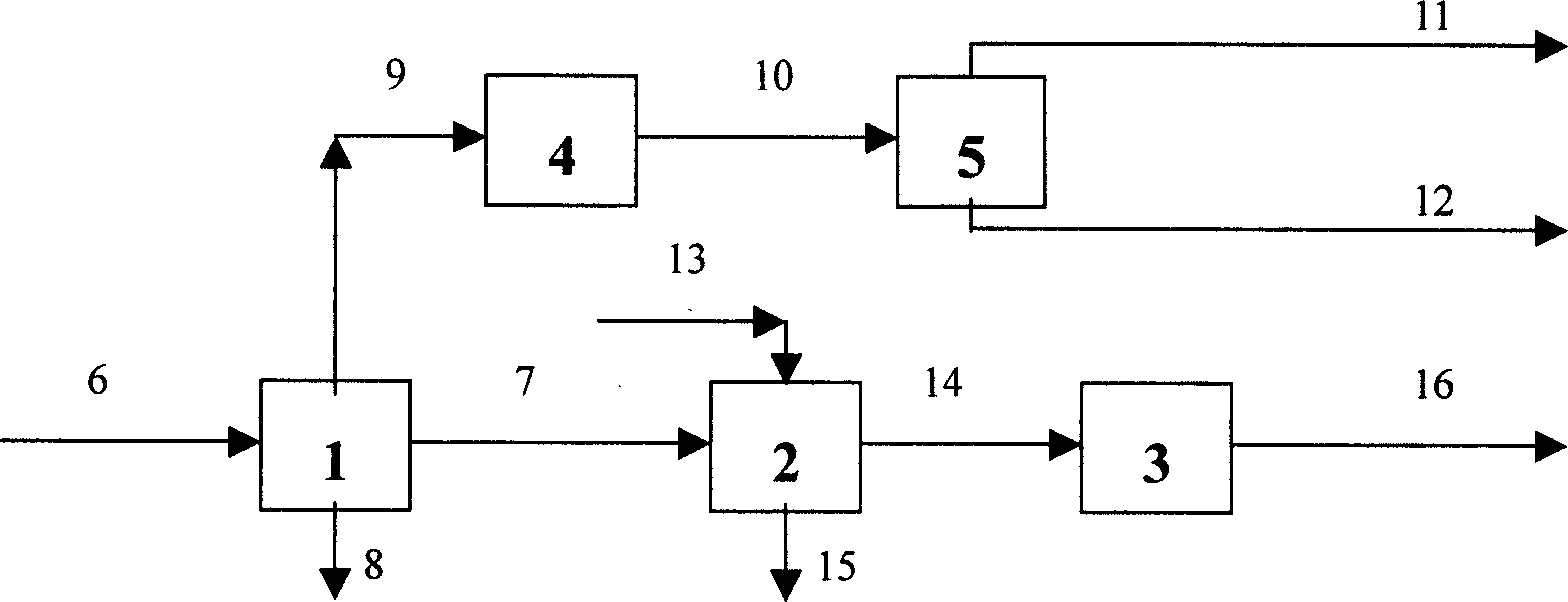

[0027] use figure 1Diethylene glycol is pumped into the reaction still 1 from the pipeline 6, and then boric acid is added to the reaction still 1 in a ratio of 1:40 to diethylene glycol, the stirring is started, and silica gel or zeolite molecular sieve is added to strengthen the distillation agent . Gradually raise the temperature to 135°C and keep it constant. At the same time, start the vacuum pump through the pipeline 11 and open the condensed water of the reflux condenser 4; adjust the residual pressure in the kettle and the amount of reflux condensed water through the valve to control the temperature at the outlet of the cooling reflux device during the esterification process. higher than 120°C. As the reaction proceeds, gradually increase the vacuum until the residual pressure in the reaction still 1 is maintained at -0.085MPa. When the extract no longer increases at last, close the cooling water of the reflux condenser 4 on the top of the tank, and when the outlet t...

Embodiment 2

[0029] use figure 1 Diethylene glycol is pumped into the reaction still 1 from the pipeline 6, and then boric acid is added to the reaction still 1 in a ratio of 1:55 to diethylene glycol, the stirring is started, and silica gel or zeolite molecular sieve is added to strengthen the distillation agent . Gradually raise the temperature to 128°C and keep it constant. At the same time, start the vacuum pump through the pipeline 11 and open the condensed water in the reflux condenser 4; adjust the residual pressure in the kettle and the amount of reflux condensed water through the valve to control the temperature at the outlet of the cooling reflux device during the esterification process. higher than 120°C. As the reaction proceeds, gradually increase the vacuum until the residual pressure in the reaction still 1 is maintained at -0.095MPa. When the extract no longer increases at last, close the cooling water of the reflux condenser 4 on the top of the tank, and when the outlet ...

Embodiment 3

[0031] use figure 1 Diethylene glycol is pumped into the reaction still 1 from the pipeline 6, and then boric acid is added to the reaction still 1 in a ratio of 1:45 to diethylene glycol, the stirring is started, and silica gel or zeolite molecular sieve is added to strengthen the distillation agent . Gradually raise the temperature to 138°C and keep it constant. At the same time, start the vacuum pump through the pipeline 11 and open the condensed water of the reflux condenser 4; adjust the residual pressure in the kettle and the amount of reflux condensed water through the valve to control the outlet temperature of the cooling reflux device during the esterification reaction. higher than 120°C. As the reaction proceeds, gradually increase the vacuum until the residual pressure in the reaction still 1 is maintained at -0.090MPa. When the extract no longer increases at last, close the cooling water of the reflux condenser 4 on the top of the tank, and when the outlet temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com