Method for preparing high-temp. superconductive Josephson junction by using refractory micromask process

A high-temperature superconducting and high-temperature superconducting thin film technology, applied in the manufacture/processing of superconductor devices, devices containing a node of different materials, etc., can solve the problem of loss of superconducting properties, residual phosphoric acid solution, thin film easy to lose oxygen, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

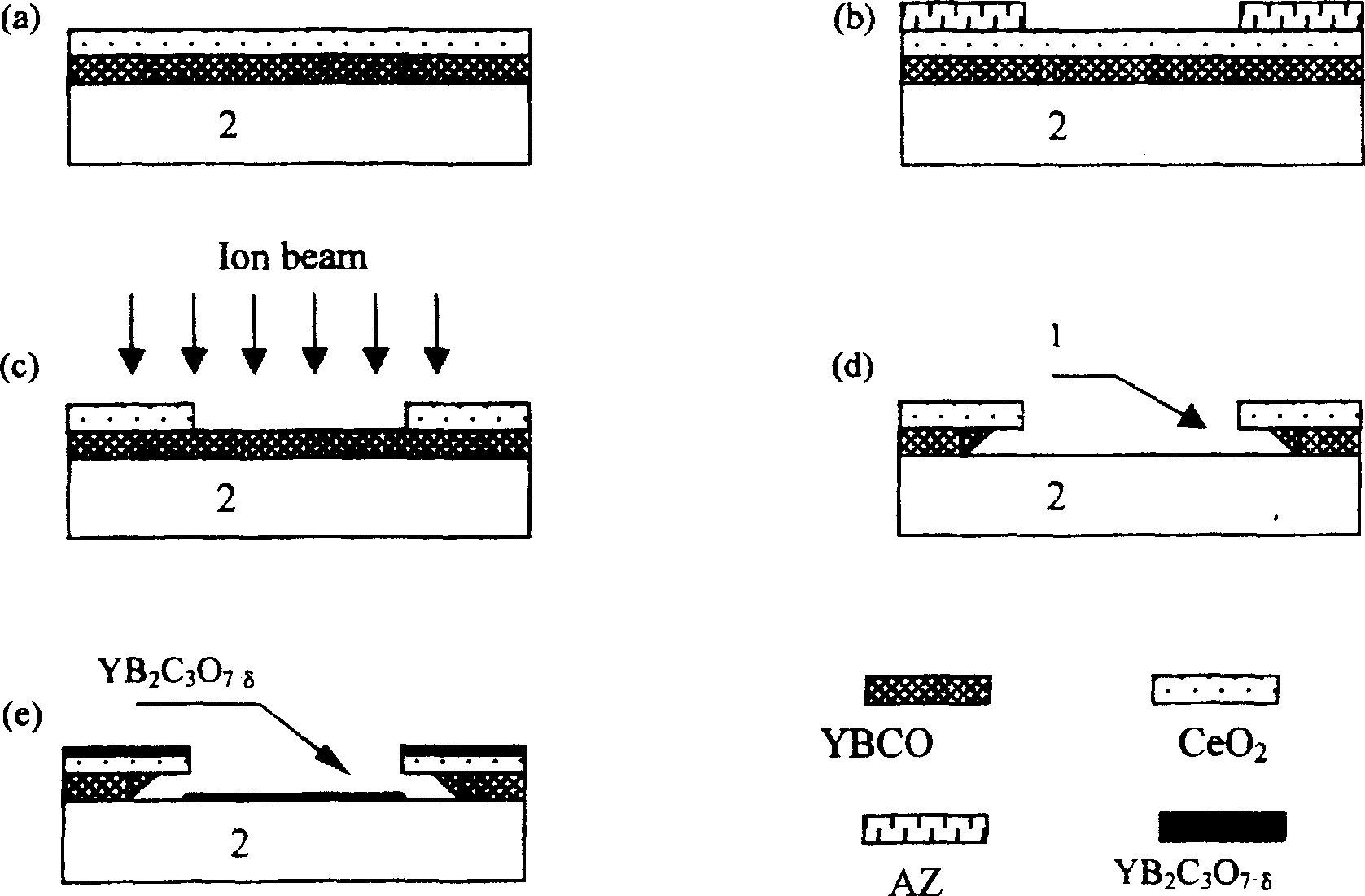

[0015] The main process of the preparation of the melting-resistant micro-mask method of the present invention:

[0016] In the process of preparing the Josephson double crystal junction of the high-temperature superconducting mixer, the melting-resistant micro-mask method is used. The process flow of Josephson double crystal junction prepared by melt-resistant micro-mask method is as follows: figure 2 As shown, the main process is briefly introduced as follows:

[0017] A YSZ (zirconia) twin crystal substrate (5mm×10mm) polished on one side is selected, and the twin crystal angle is 24°.

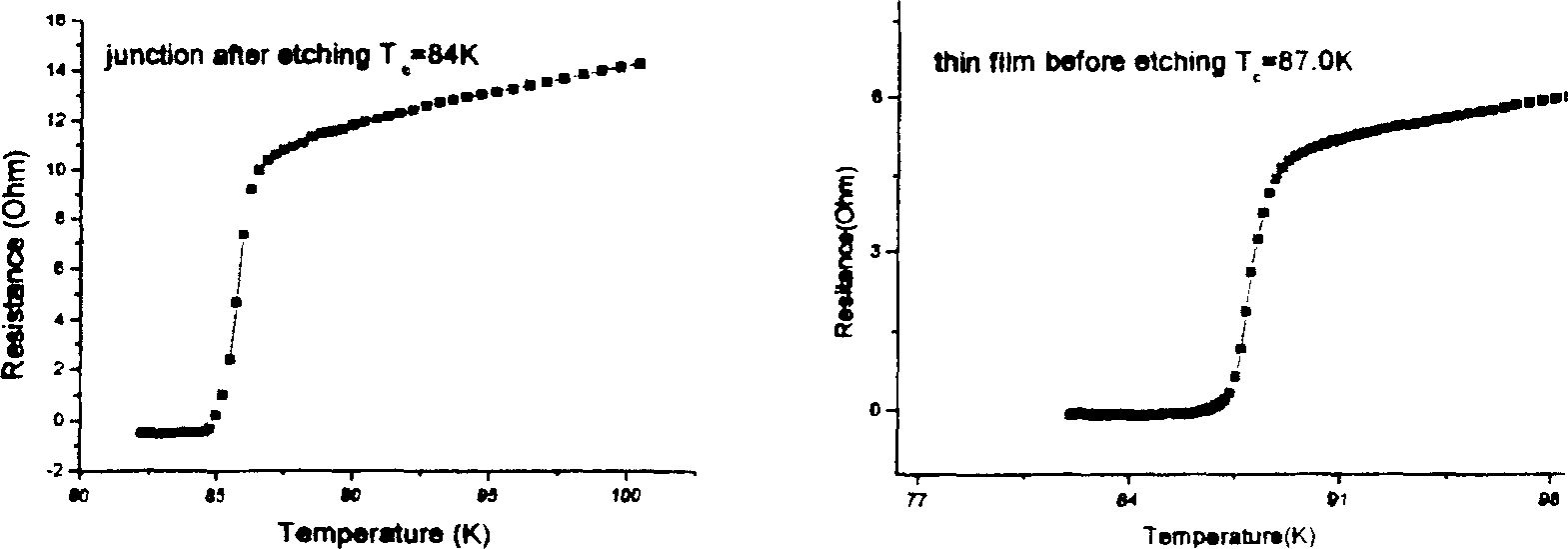

[0018] 1. Preparation of CeO on YSZ substrate by in situ preparation method 2 / YBCO double layer film, such as figure 2 (a) shown. CeO 2 About 1500 Å thick, the YBCO layer is greater than 5000 Å thick. This layer of YBCO is used as a dielectric film and also plays a supporting role in suspending the micro-mask layer. It is not expected to be superconducting, so it is deposited at 35...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com