Oil-water separator for treating oil-containing waste water

An oil-water separator and oil-water separation technology, applied in the field of water treatment, can solve the problems of increased sewage treatment cost, process overload work, poor sewage adaptability, etc., to achieve easy monitoring, control and management, increase cross-sectional area of water, and recycle Effect of Utilization Ratio Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

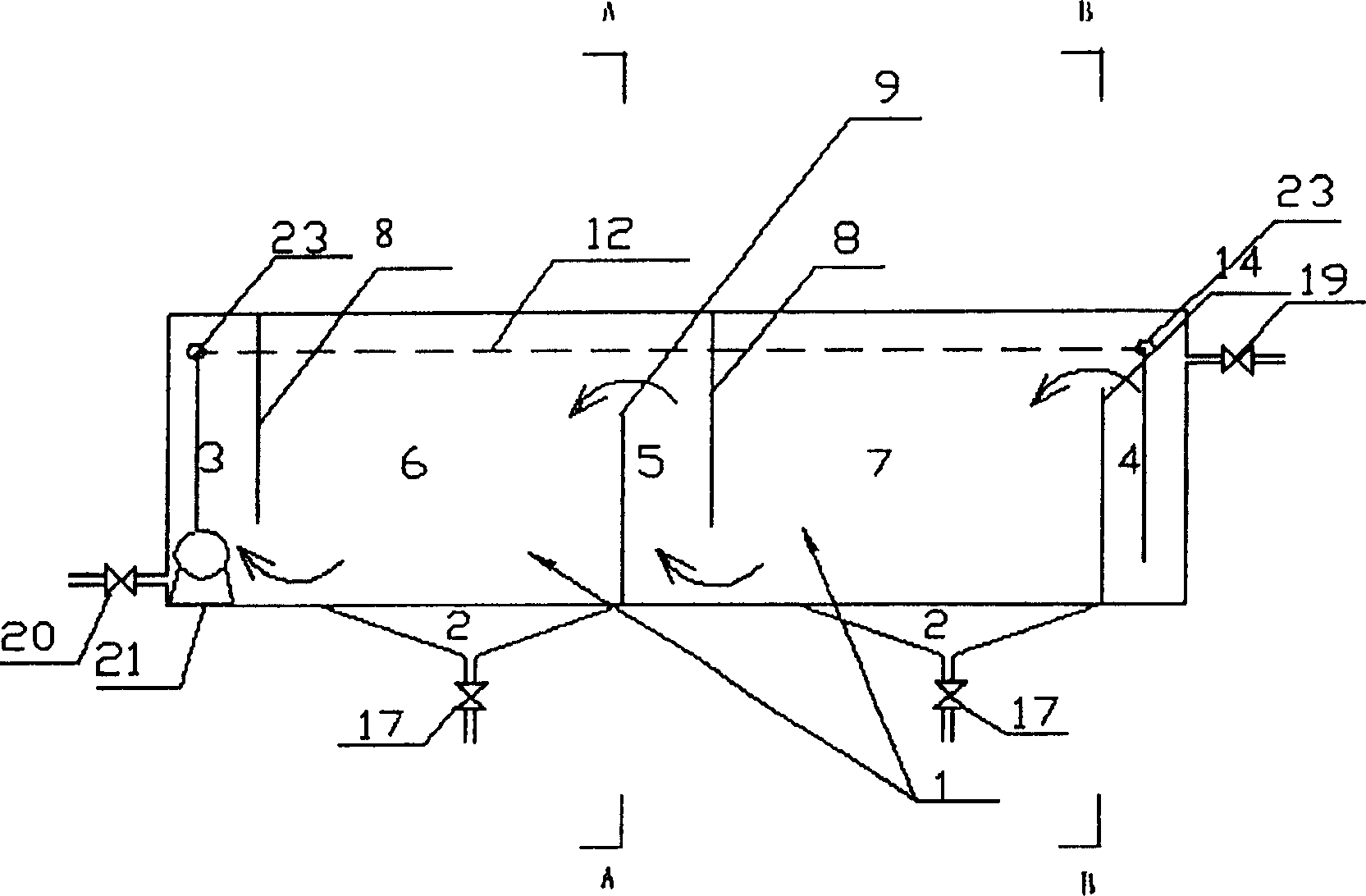

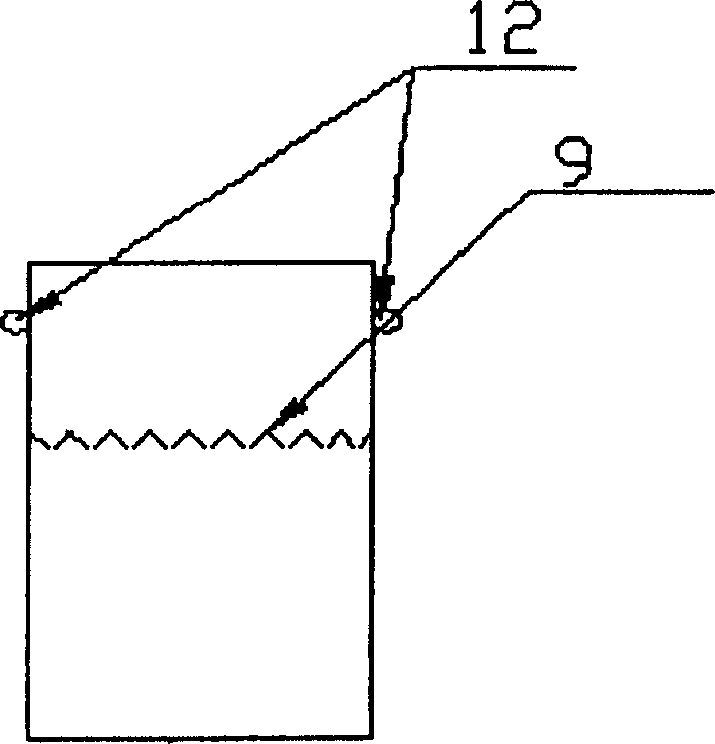

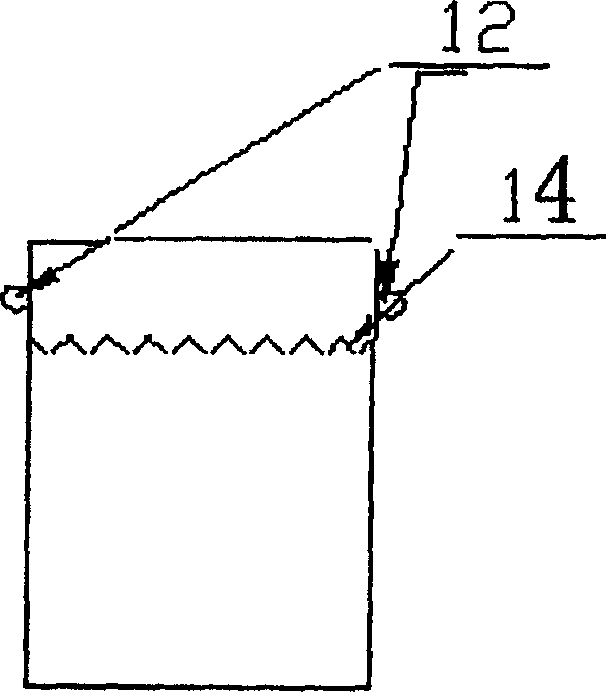

[0018] The oily waste water of an oil field is processed through the common grease trap and the oil-water separator of the present invention at the same time: as Figure 1~3 As shown, the present invention uses the separator as a whole as a reactor, has a multi-stage circulating oil-water separation structure, and mainly consists of five areas: oil-water separation area 1, mud discharge area 2, water outlet area 3, water inlet area 4 and water distribution area 5 The oil-water separation zone 1 is a two-level structure, which is composed of the left separation zone 6 and the right separation zone 7, and the water distribution zone 5, which is composed of the partition plate 8 installed from the upper part and the overflow plate 9 installed from the lower part, is located on the left Between the separation area 6 and the right separation area 7; there is a gap between the separation plate 8 and the bottom of the reactor, so that the water flow can pass through its lower part, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com