Thermally driven on line test structure of transverse breaking strength of film in microelectronic mechanical system

A micro-electro-mechanical, transverse fracture technology, applied in the direction of strength characteristics, the use of stable tension/pressure to test the strength of materials, measurement devices, etc., can solve the trouble of reading, the accuracy of measurement is greatly affected, and it is easy to be disturbed by external factors. and other problems, to achieve the effect of simple test, small voltage and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] specific implementation plan

[0012] The specific structure of the embodiment of the present invention will be further described below in conjunction with the accompanying drawings:

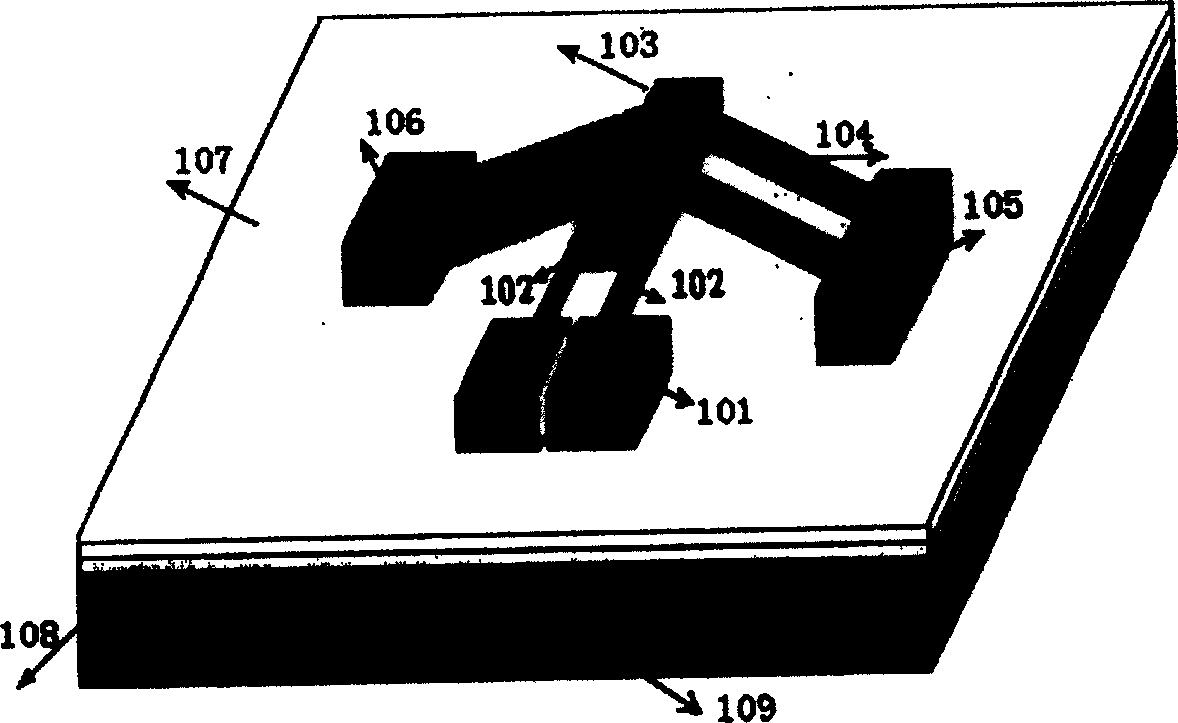

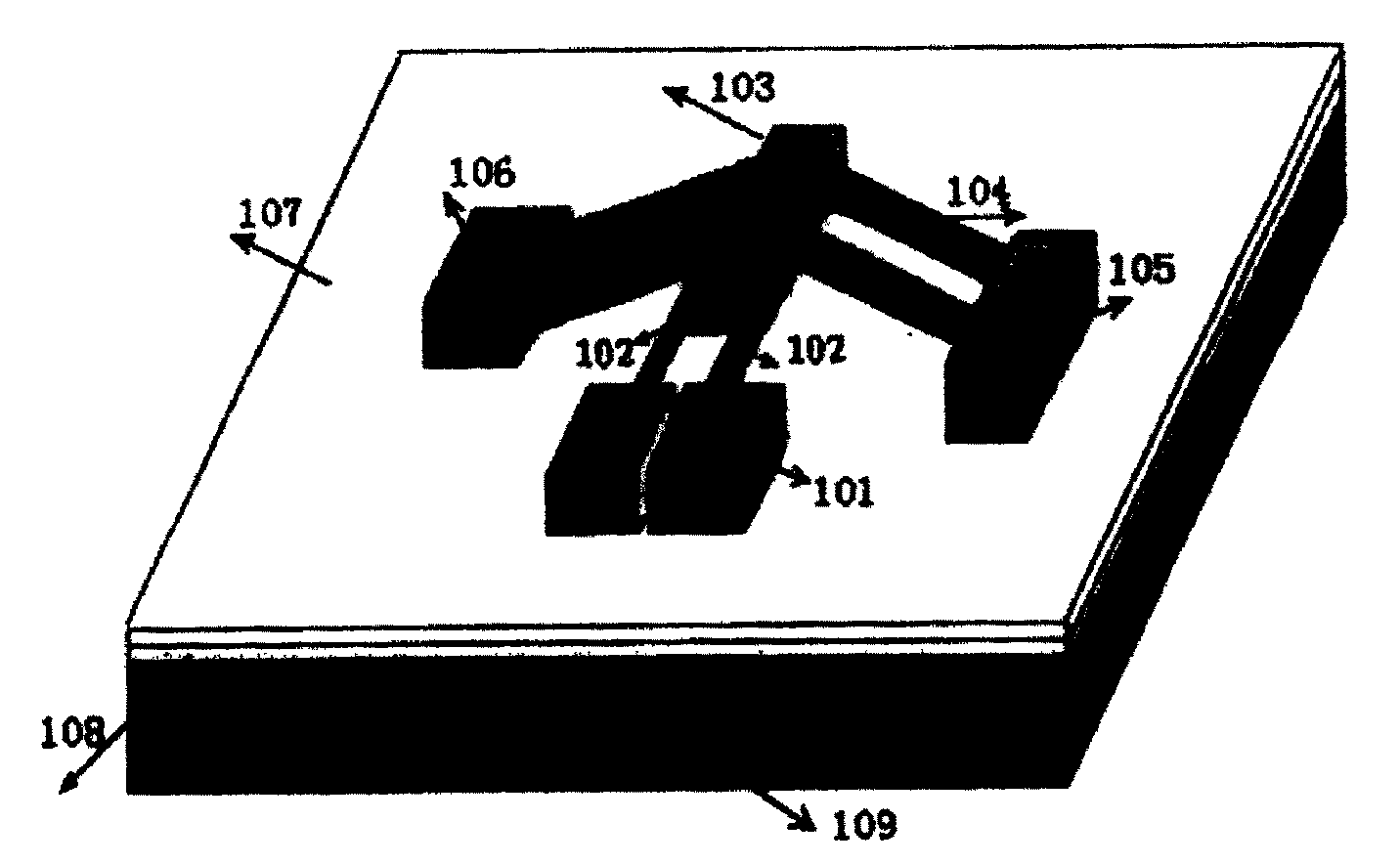

[0013] figure 1 It is a three-dimensional schematic diagram of the test structure for measuring tensile breaking strength. On a silicon substrate material, a microelectronic processing technology is used to fabricate a device such as figure 1 In the structure shown, the beam 102 to be tested is 10 microns long and 2 microns wide, one end is connected to the beam fixing seat 1 to be tested, the other end is connected to the connecting beam 103, the two sides of the connecting beam 103 are connected to the V-shaped thermal actuator heating beam 104 connected, each heating beam is 5 microns wide and 300 microns long, and there are 4 in total; the other end of the heating beam is connected to the heating beam fixing seat 105 respectively; the beam fixing seat 101 to be tested and the heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com