Apparatus for refining royal jelly

A technology of royal jelly and utensils, which is applied in the fields of application, beekeeping, food preparation, etc., and can solve problems such as laboriousness, uncertain circulation, and unstable mesh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

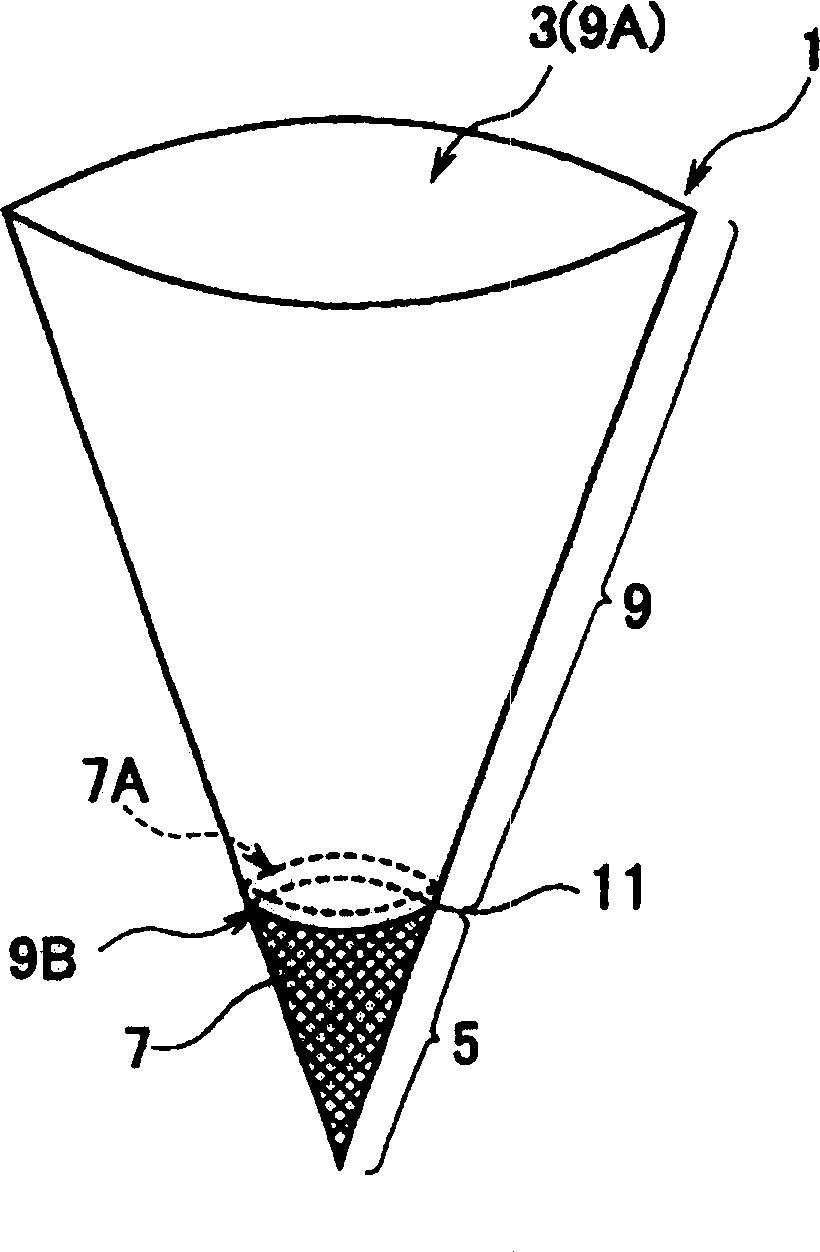

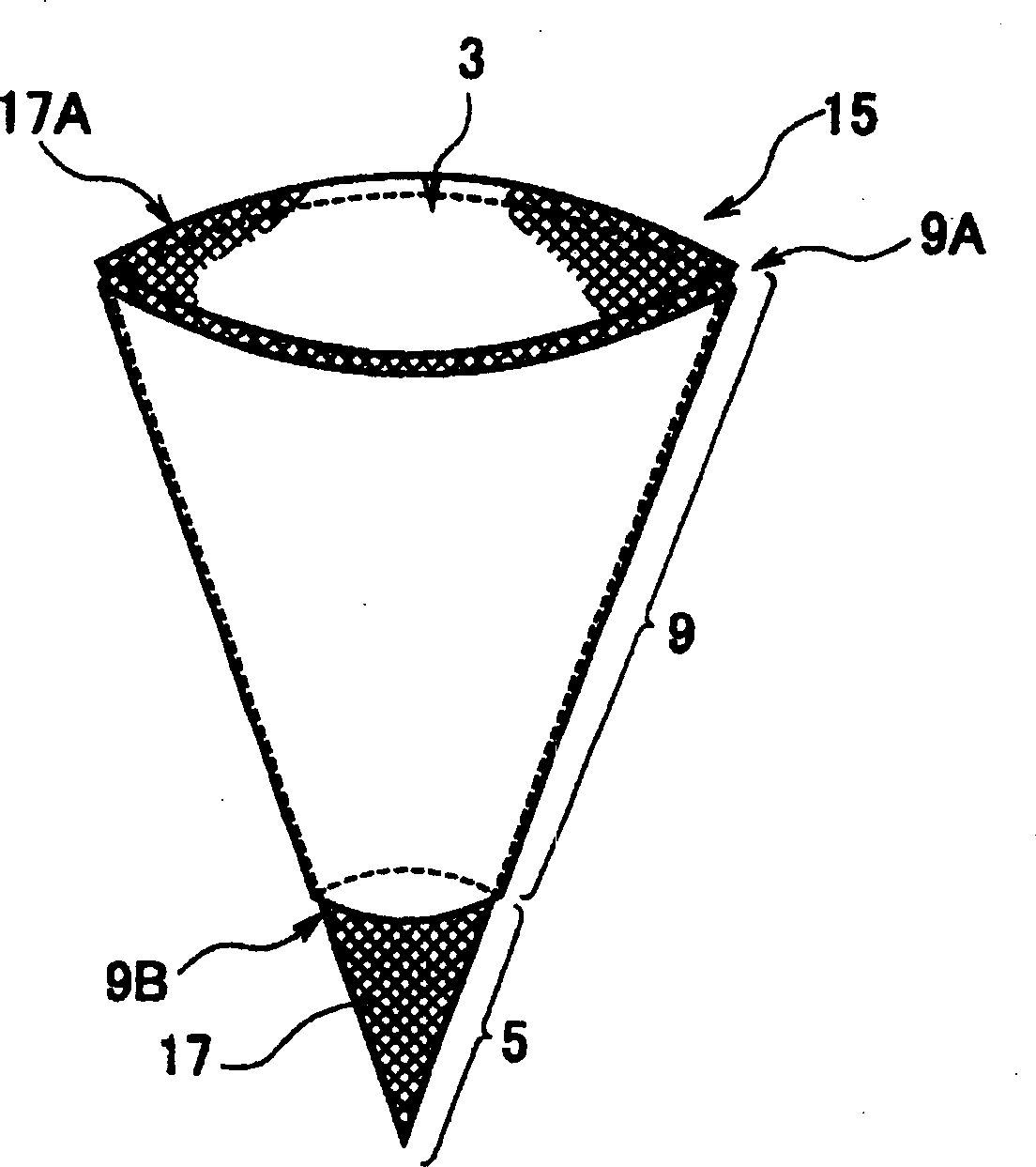

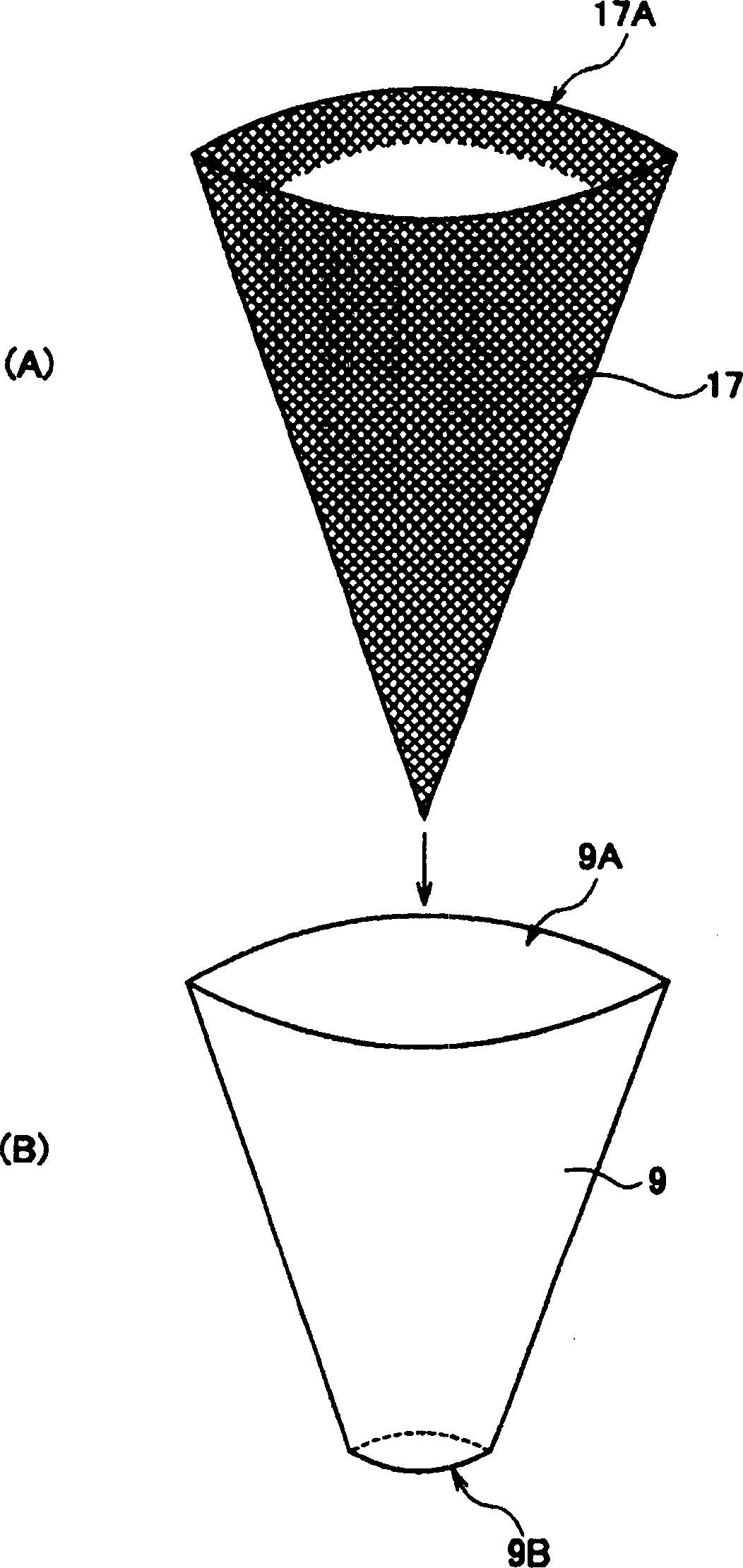

[0041] Embodiments of the present invention will be described below with reference to the drawings.

[0042] refer to figure 1 The utensil 1 for refining royal jelly according to Embodiment 1 is formed in a bag-shaped body that has an opening 3 at one end for receiving royal jelly and can be expanded into a substantially conical shape, and a filter 7 is arranged at the front end of the bag-shaped body, which constitutes The filter part 5 which squeezes out the royal jelly accommodated in this bag-shaped body, and filters and refines it.

[0043] In addition, the above-mentioned filter 7 is a filter cloth made of synthetic fiber mesh or non-woven fabric. The net is no problem either. The mesh size is more preferably 0.1 mm to 0.8 mm, most preferably 0.1 mm to 0.5 mm. Therefore, the weaving method of the filter cloth is to form a mesh, so the weaving mesh does not twist, so the state of filtering and refining is stable, and high-purity and high-quality royal jelly can be obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com