Improved flash-spun sheet material

A sheet and filamentary technology, applied in flash spinning, adding pigments to spinning solution, spinning, etc., can solve the problems of insufficient flexibility, excessive weight and volume of printed sheets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

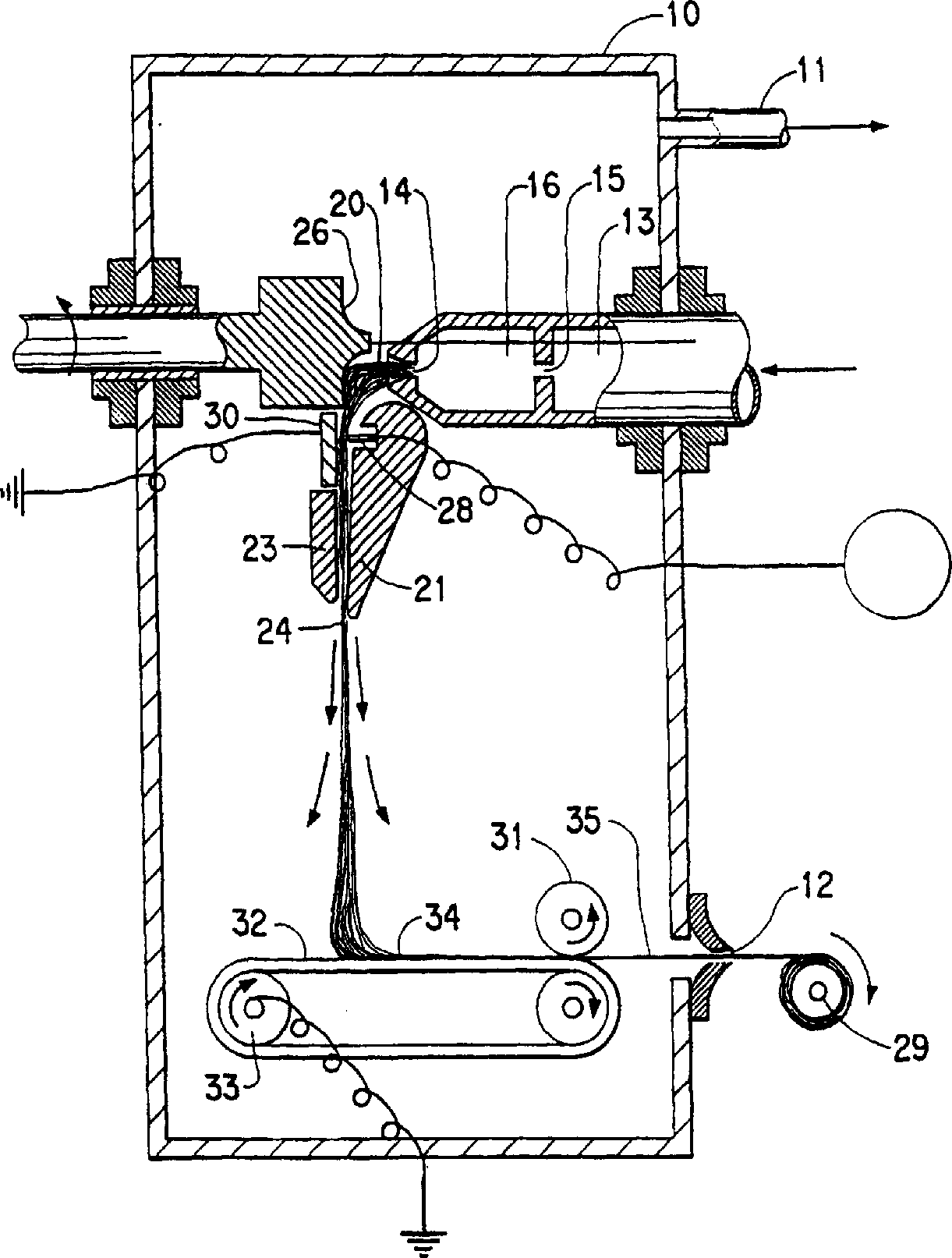

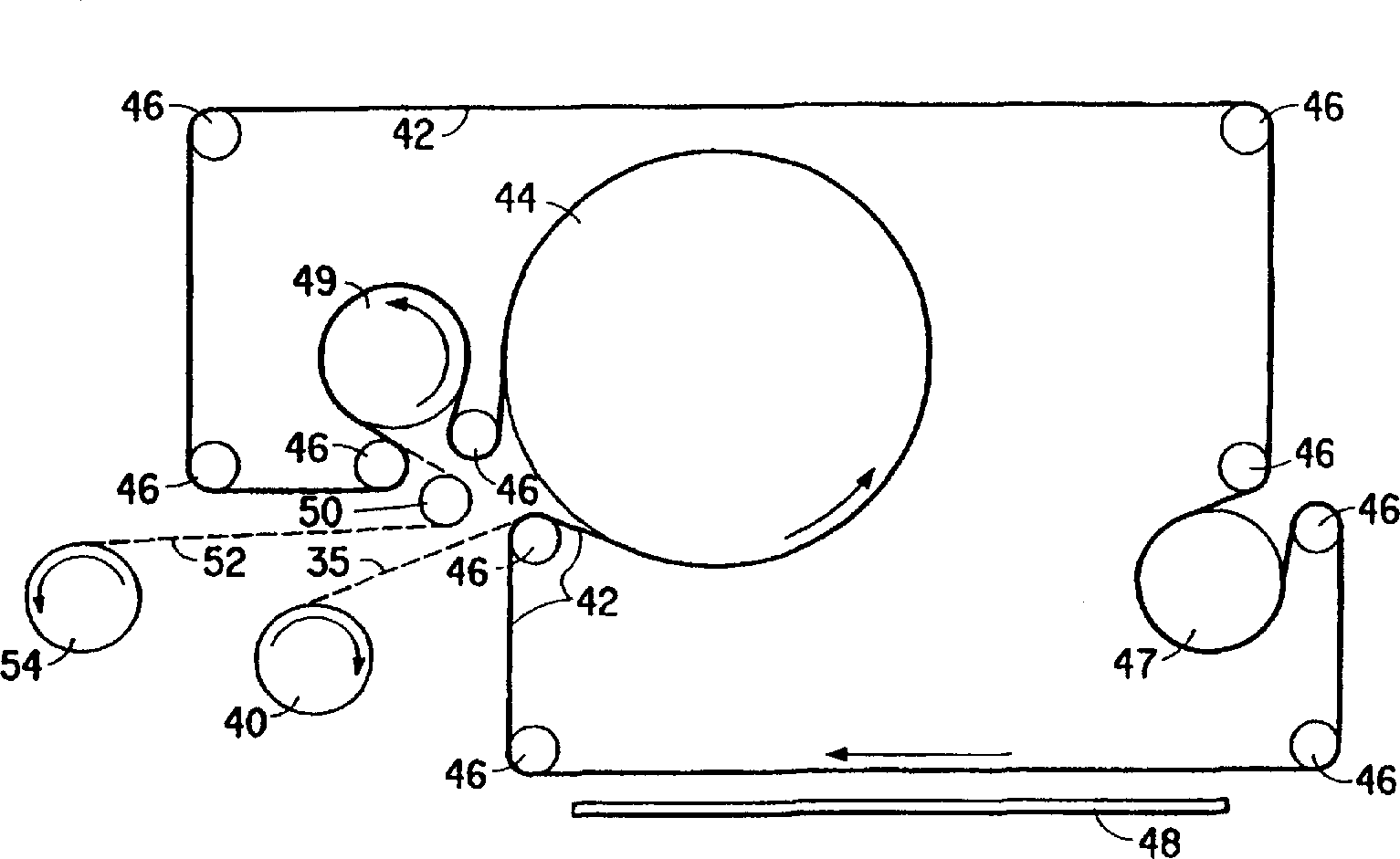

Method used

Image

Examples

Embodiment

[0045] In the above description and the following non-limiting examples, the following test methods were used to determine the characteristics and properties given. ASTM refers to the American Society for Testing and Materials, and TAPPI refers to the Technical Association of the Pulp and Paper Industries. ISO refers to the International Organization for Standardization, while ANSI refers to the American National Standards Institute.

[0046] Basis weight, determined in accordance with ASTM D-3776 (which method is hereby incorporated by reference) and expressed in g / m 2 is given for the unit. The basis weights given in the following examples are each based on the average of at least 12 measurements made on the sheet.

[0047] The delamination strength of the sheet samples is determined using a constant rate of extension tensile tester, such as an Instron benchtop tensile tester. For a 1.0 inch (2.54 cm) x 8.0 inch (20.32 cm) sample, separation and delamination were induced ...

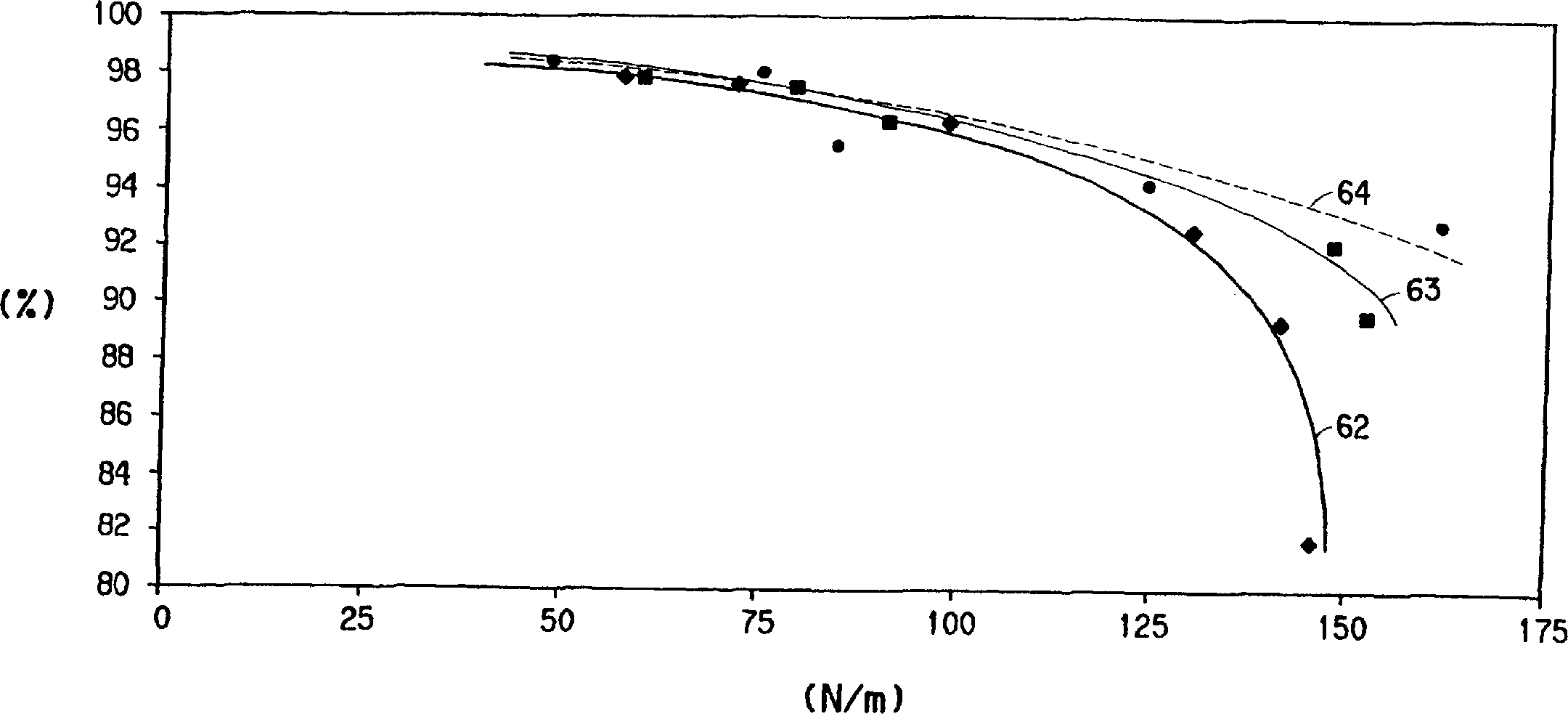

example 7~12

[0089] In Examples 7-12, the flash-spinning and bonding of polyethylene ultrafine plexifilamentary film fibril sheets was essentially the same as described in Comparative Examples 3-5, except that the polyethylene was mixed with the solvent before Titanium dioxide from Example 1 was added to polyethylene.

[0090] In Examples 7-9, masterbatches were prepared by mixing R104-type neutralized rutile titanium dioxide into the high-density polyethylene in Comparative Examples 3-5 at an incorporation ratio of 50% by weight of the polymer. The masterbatch was obtained under the tradename White HDPE MB 510710 from Ampacet Europe S.A. (Messancy, Belgium) in the form of pellets. This masterbatch was then tumble mixed with the polyethylene of Comparative Examples 3-5 to form a mixture consisting of 96% polyethylene and 4% rutile titanium dioxide. The mixture was added to the spinning medium of Comparative Examples 3-5 in the same ratio as that of Comparative Examples 3-5 to prepare a sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com