Periodical stepped quenching cooling equipment

A technology of cooling equipment and graded quenching, which is applied in the field of graded quenching cooling equipment and periodic graded quenching cooling equipment. Effects of pollution and production safety issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

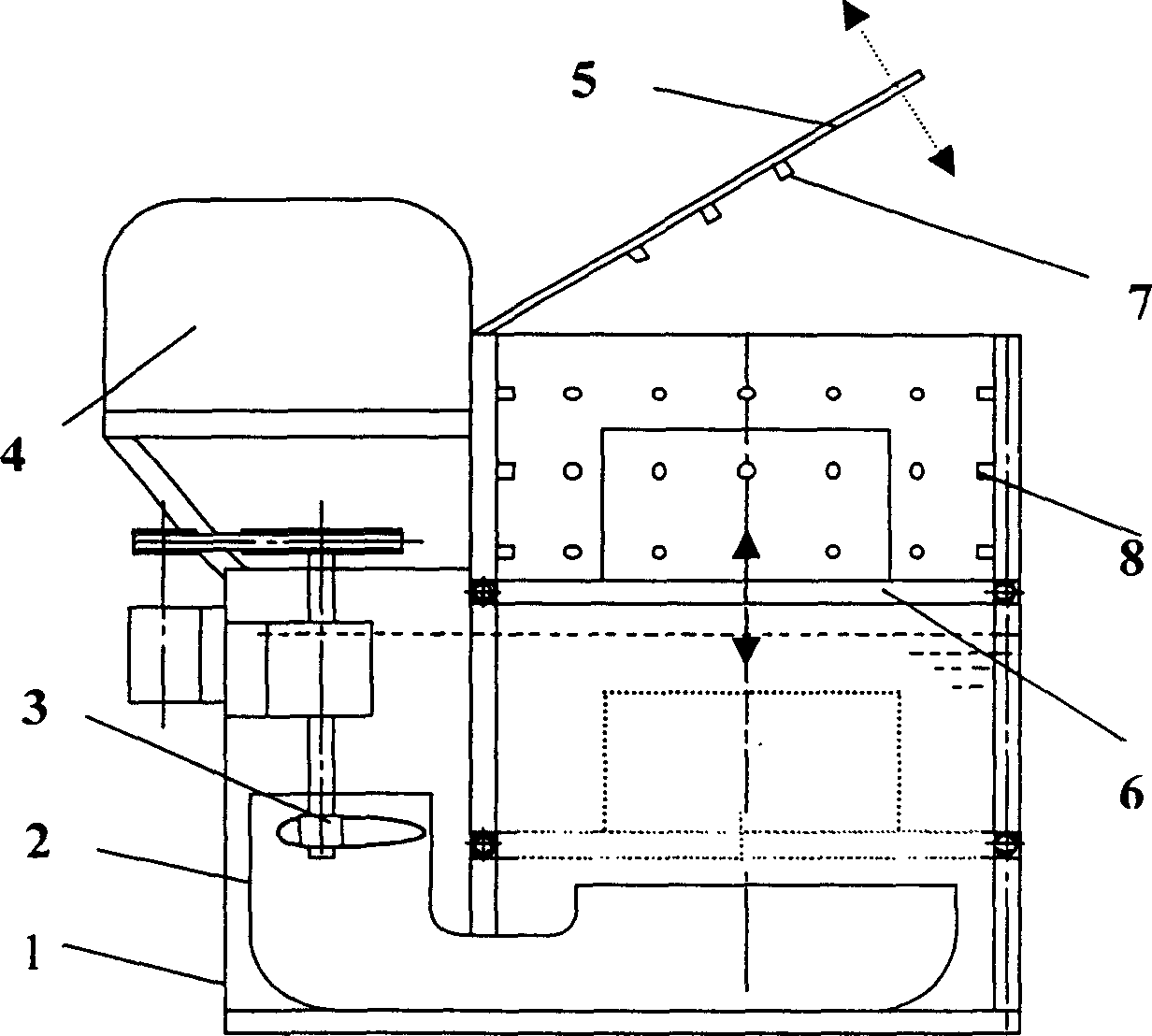

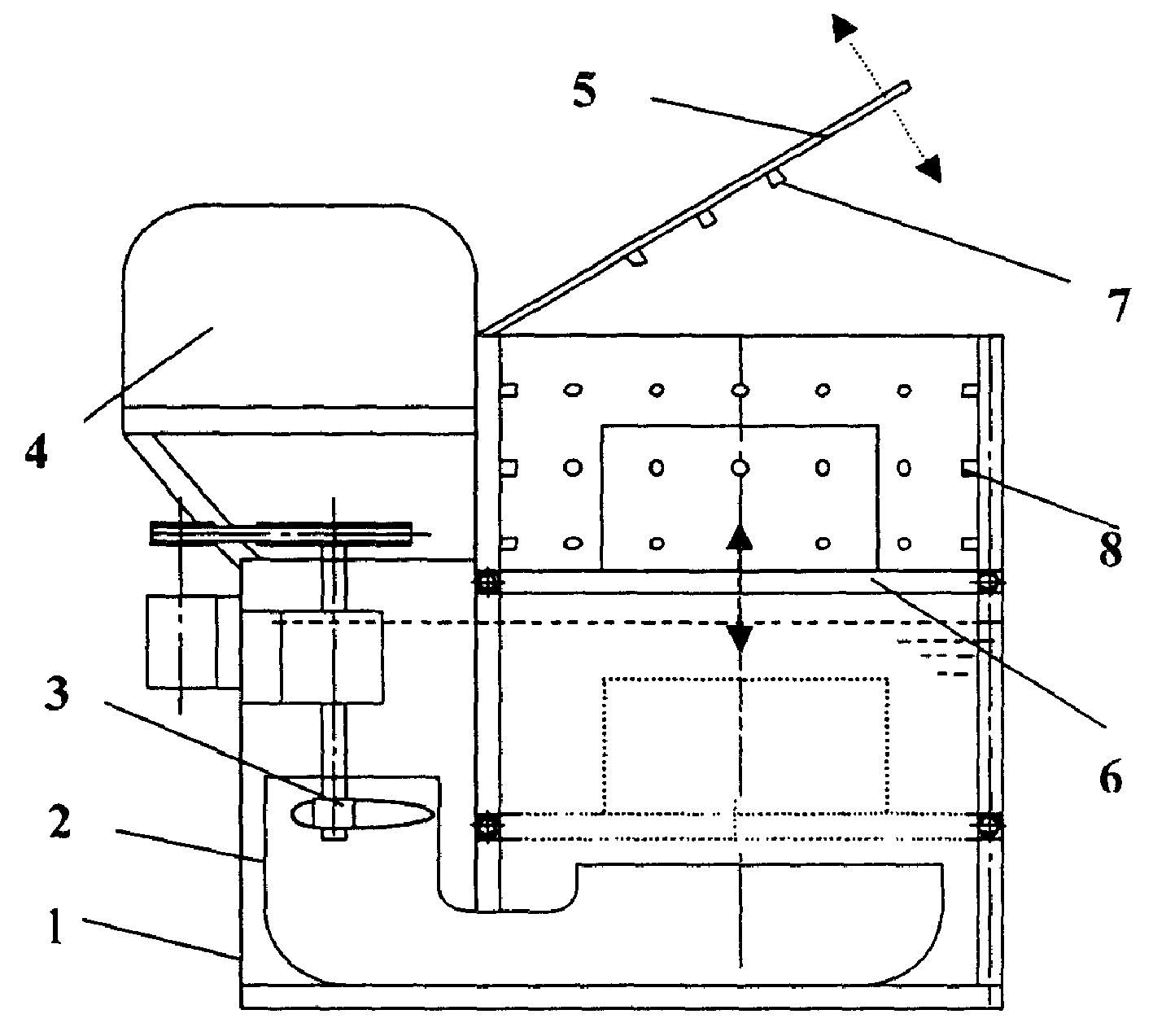

[0011] Such as figure 1 As shown, the present invention mainly includes: a tank body 1, a fluid guiding cylinder 2, a propeller agitator 3, a lifting platform driving system 4, a cover plate 5, a lifting platform 6, a nozzle 7, and a nozzle 8, and the connection mode is: in the tank body One side of 1 is provided with a propeller agitator 3, the propeller of the propeller agitator 3 extends below the liquid surface, the fluid guide cylinder 2 is U-shaped, the propeller of the propeller agitator 3 is inserted into an opening of the fluid guide cylinder 2, and the fluid guide cylinder 2 is another An opening is set at the bottom of the quenched part after being immersed in the liquid, and the lifting platform drive system 4 is set above the side of the tank body 1, and is connected with the lifting platform 6 and the cover plate 5. The tank body 1 is provided with a cover plate 5, and the cover plate 5 A nozzle 7 is arranged below, and a nozzle 8 is arranged above the liquid lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com