Method for producing rail infrastructure

A rail and lower layer technology, applied in the direction of track, ballast layer, track laying, etc., can solve the problems of time-consuming and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

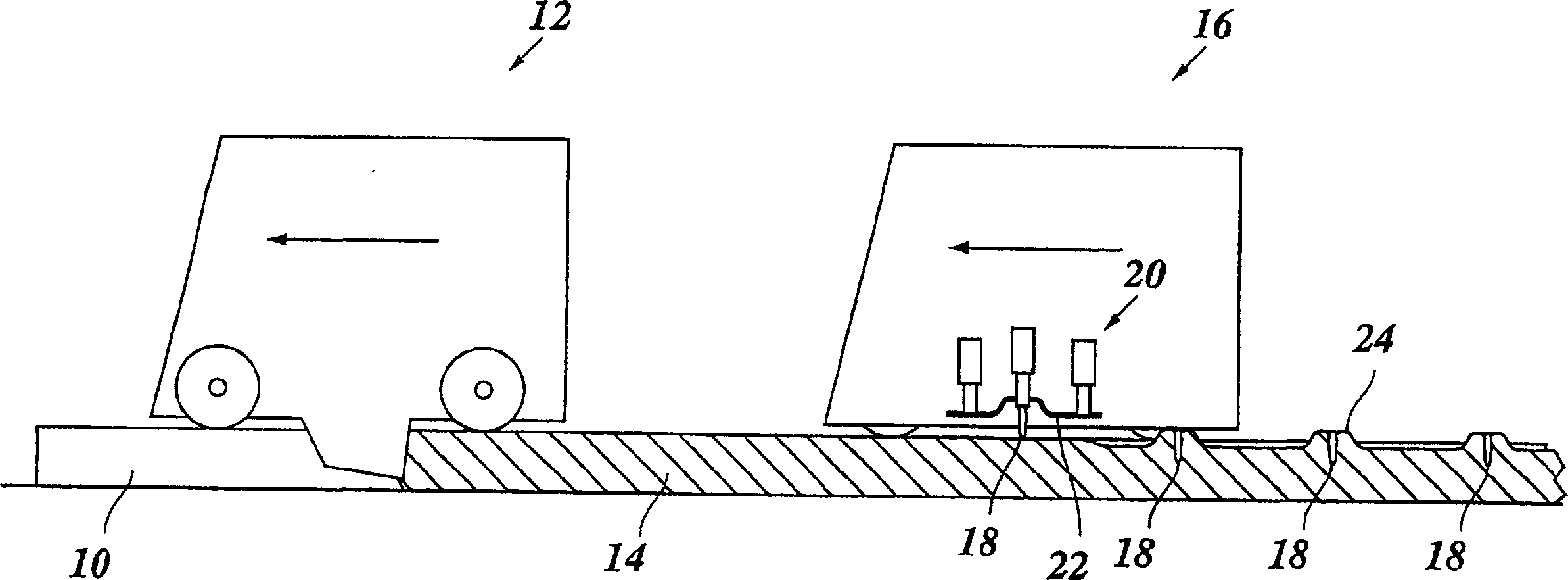

[0016] Such as figure 1 Shown method, at first will put down the temporary rail 10 that concrete delivery vehicle 12 is prepared, concrete delivery vehicle 12 just casts a straight concrete track bed 14 between two temporary rails 10 when running on temporary rail 10.

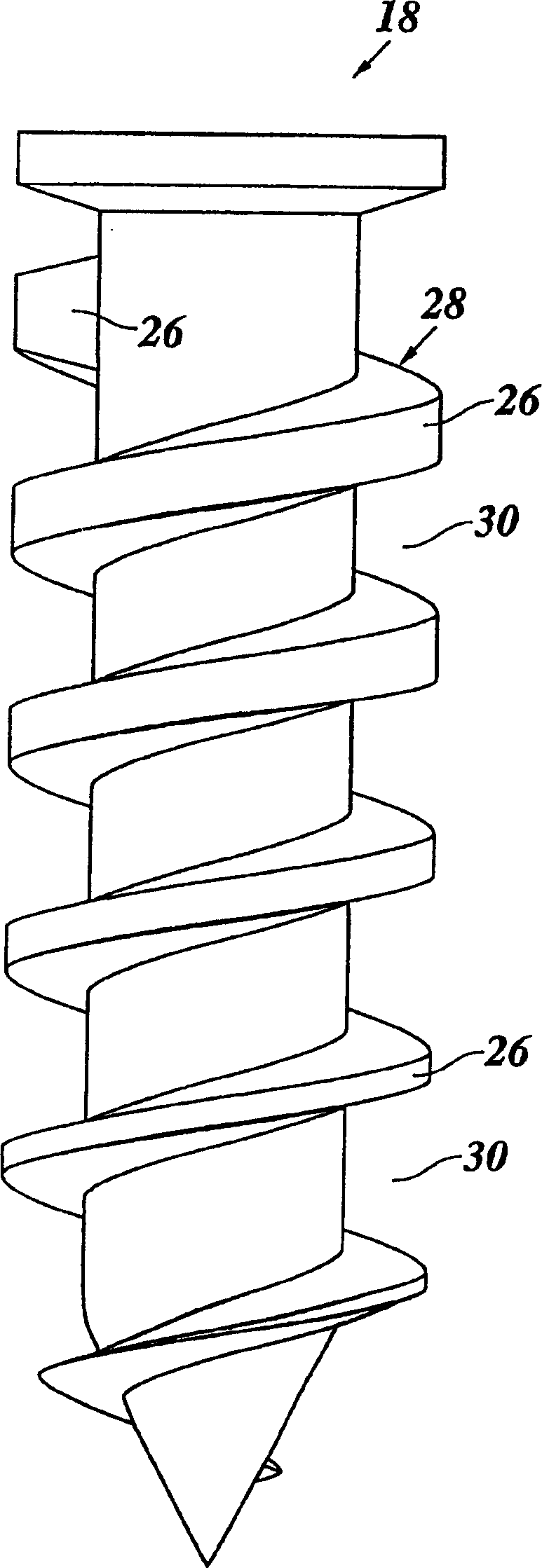

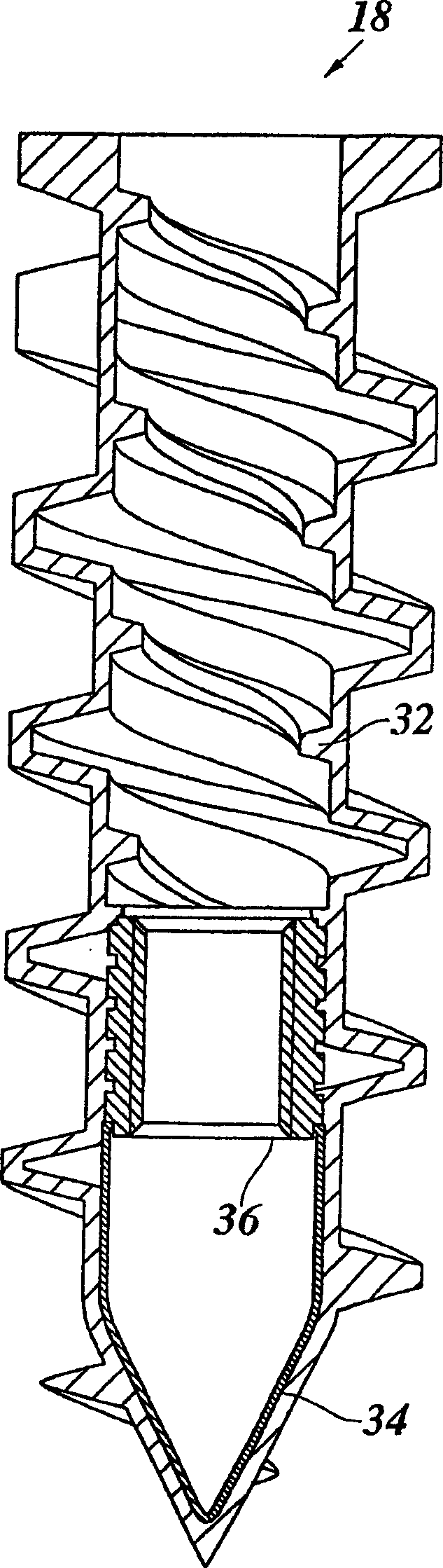

[0017] The concrete truck 12 is followed by a doweling machine 16 which also runs on the temporary rail 10 . Alternatively the doweling machine 16 could also be integrated into the concrete truck 12 . The dowel setting machine 16 presses plastic dowels 18 into the still deformable concrete at regular intervals corresponding to the separation distance between railroad ties on conventional rail substructures. After the concrete has hardened, the dowels are firmly anchored in the concrete. In each doweling step, a total of 4 dowels are installed, two for each rail on the track. However, figure 1 Only one of the four dowels is visible.

[0018] In the embodiment, the doweling machine is combined with a vibrato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com