Auxiliary driving motor

An auxiliary power and motor technology, applied in the direction of electric components, magnetic circuit rotating parts, control mechanical energy, etc., can solve the problems of power motor device failure, unsustainable power, large volume, etc., and achieve the effect of reliable use and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Example An auxiliary power motor

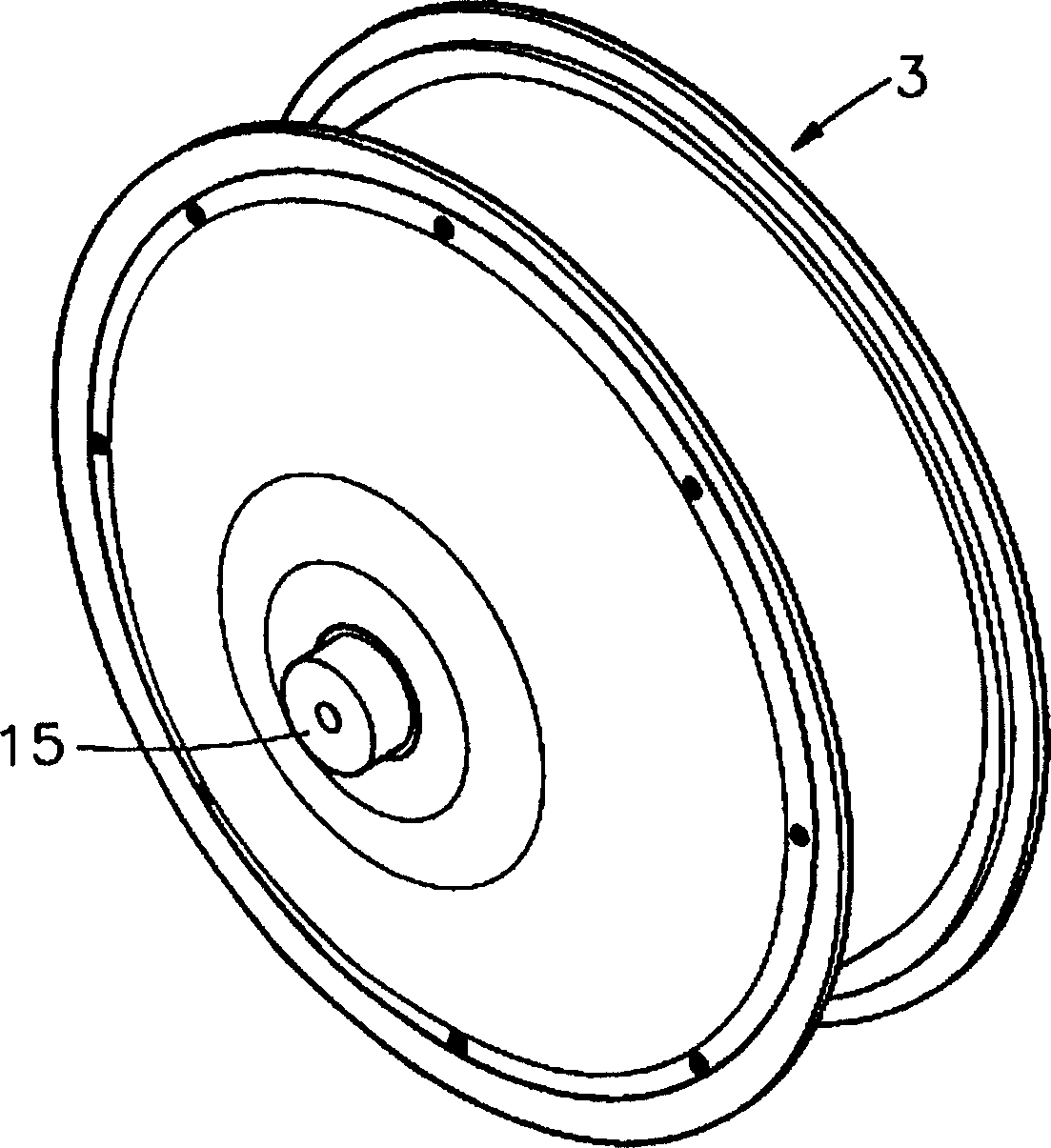

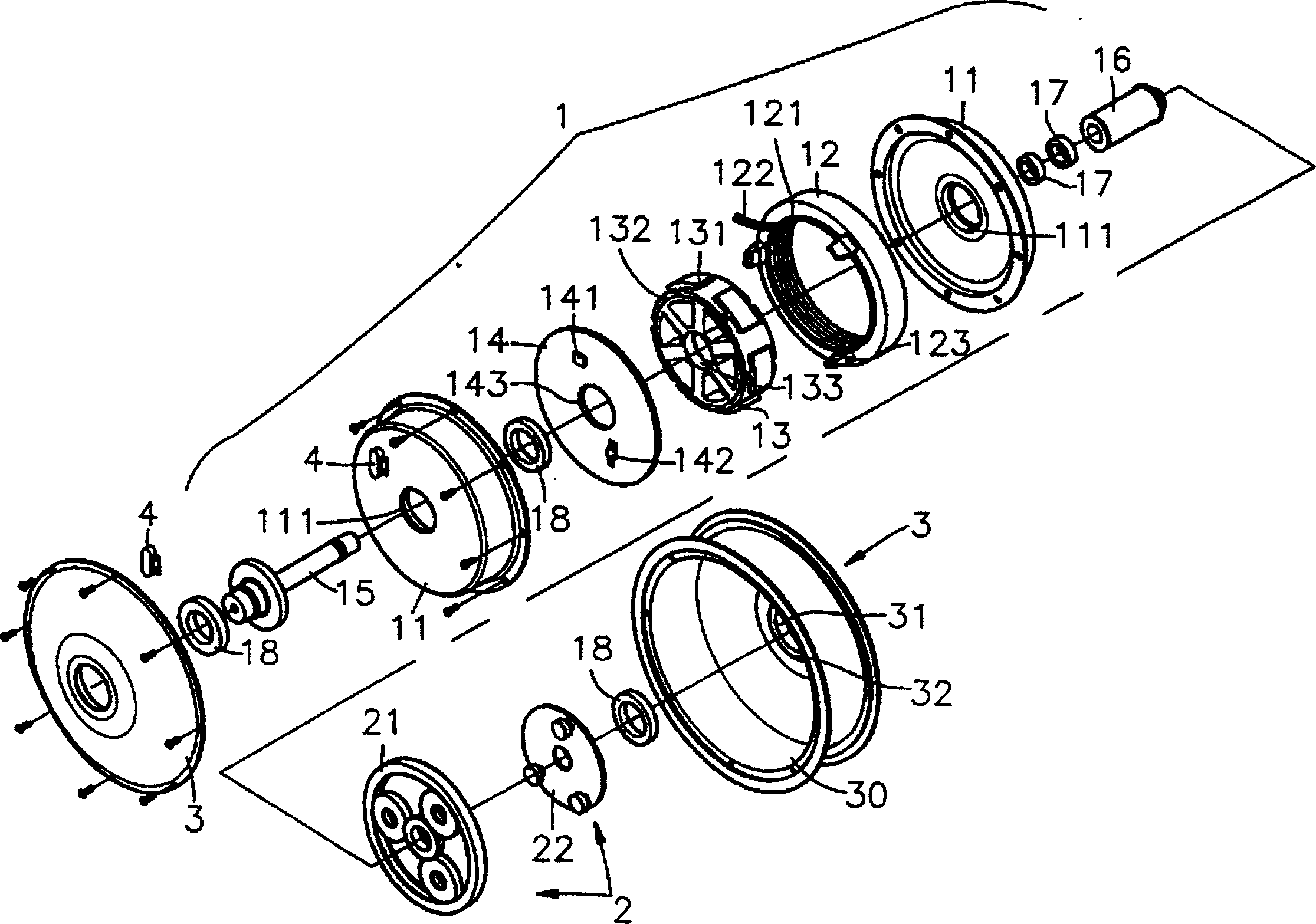

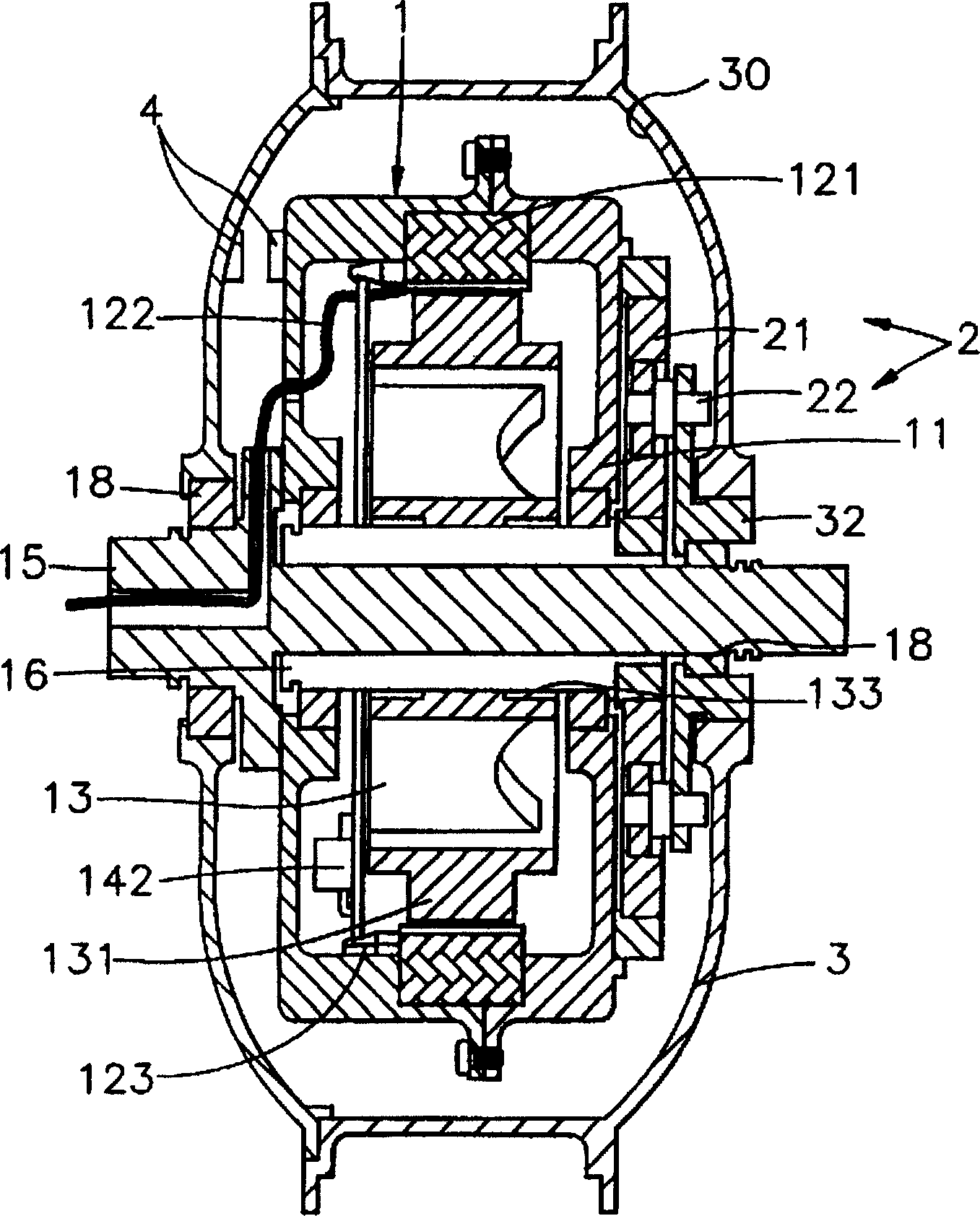

[0022] Please refer to Figures 1, 2, 3, and 4. It can be clearly seen from the figures that an auxiliary power motor in this embodiment includes an auxiliary power motor device 1, a reduction mechanism 2 and a wheel cover 3; wherein:

[0023] The accommodating space 30 of the wheel cover 3 is for accommodating the auxiliary power motor device 1 therein, and the fixed magnetic ring 12, the rotor disk 13 and the circuit board 14 are accommodated between the two shells 11 of the auxiliary power motor device 1. Inside, a plurality of stators 121 are provided at the inner diameter of the fixed magnetic ring 12, and the signal line 122 at the stator 121 is used to control whether there is electrical conduction, and a rotor disc 13 is placed inside the fixed magnetic ring 12, and the outer ring of the rotor disc 13 is A plurality of T-shaped tooth parts 131 are arranged facing upward, and accommodating chamber 130 is formed in the gap between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com