On-line turbogenerator stator winding end portion vibration monitoring device and its application

A turbogenerator and stator winding technology, applied in the direction of instruments, etc., can solve the problems of electromagnetic field interference, self-vibration and wear, and inability to make close contact with sensors, and achieve the effects of low lateral sensitivity, long service life, and stable amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation method of the present invention is described in detail below.

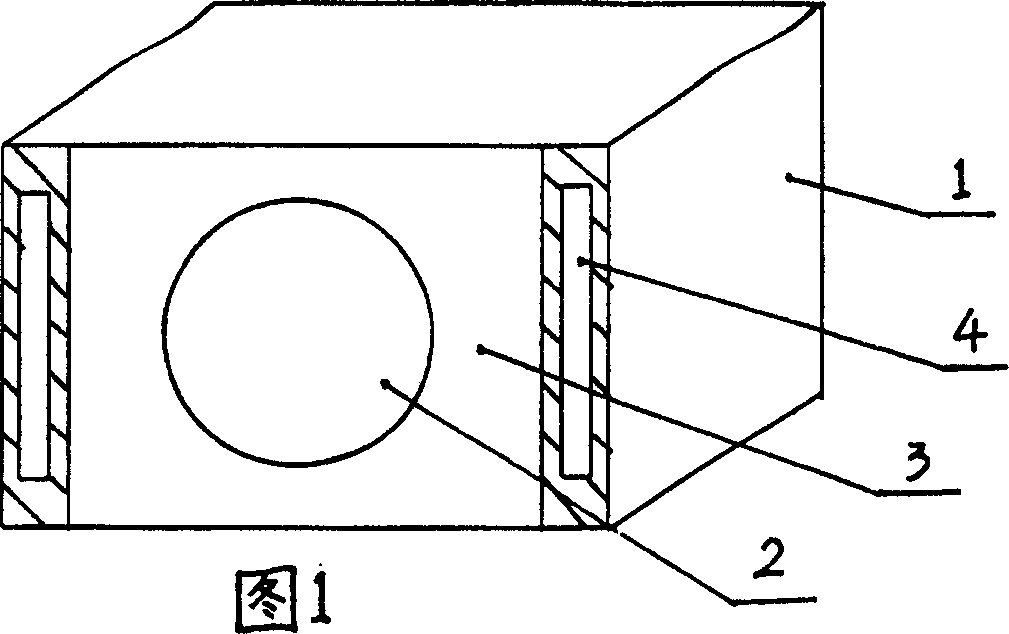

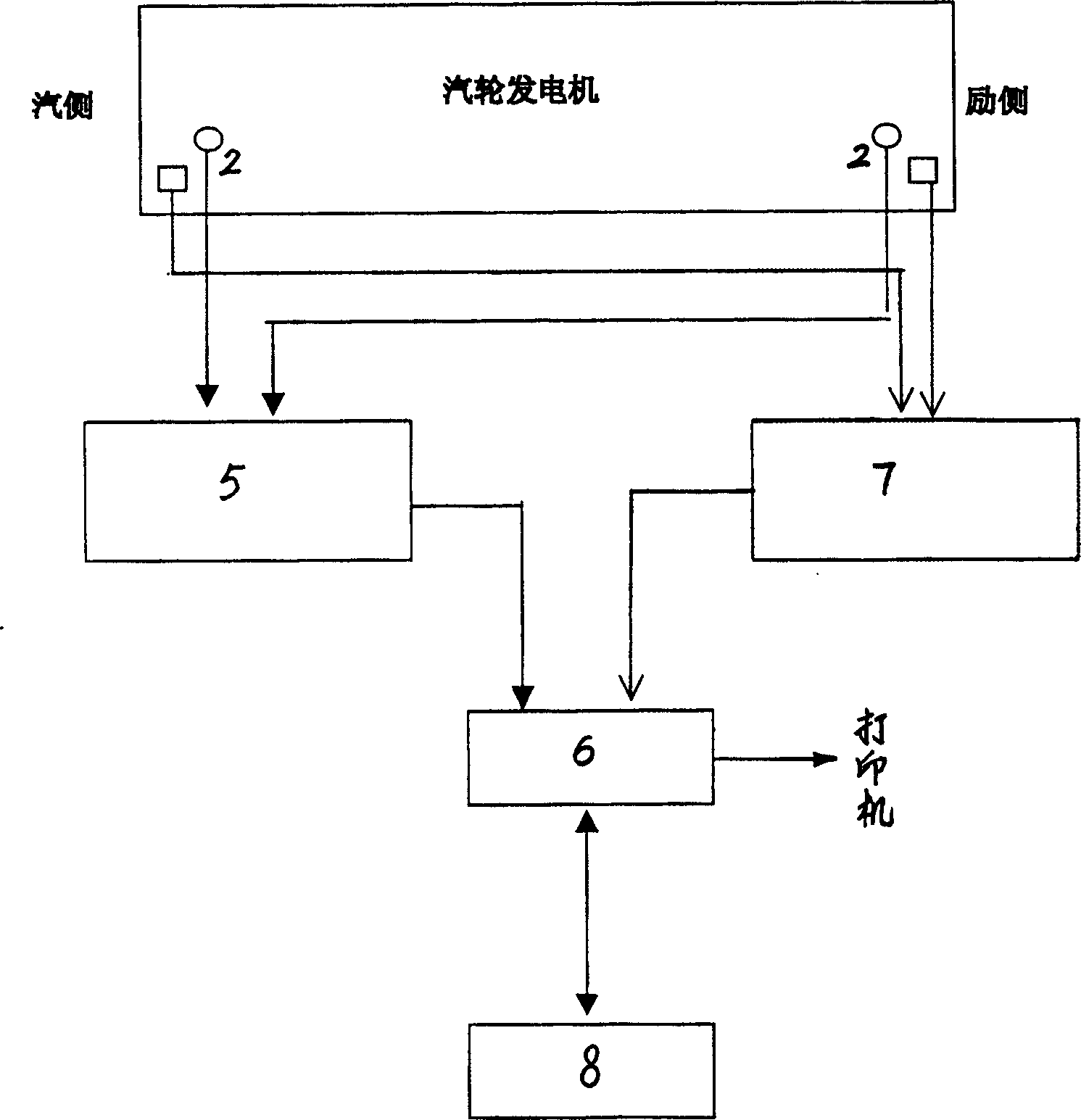

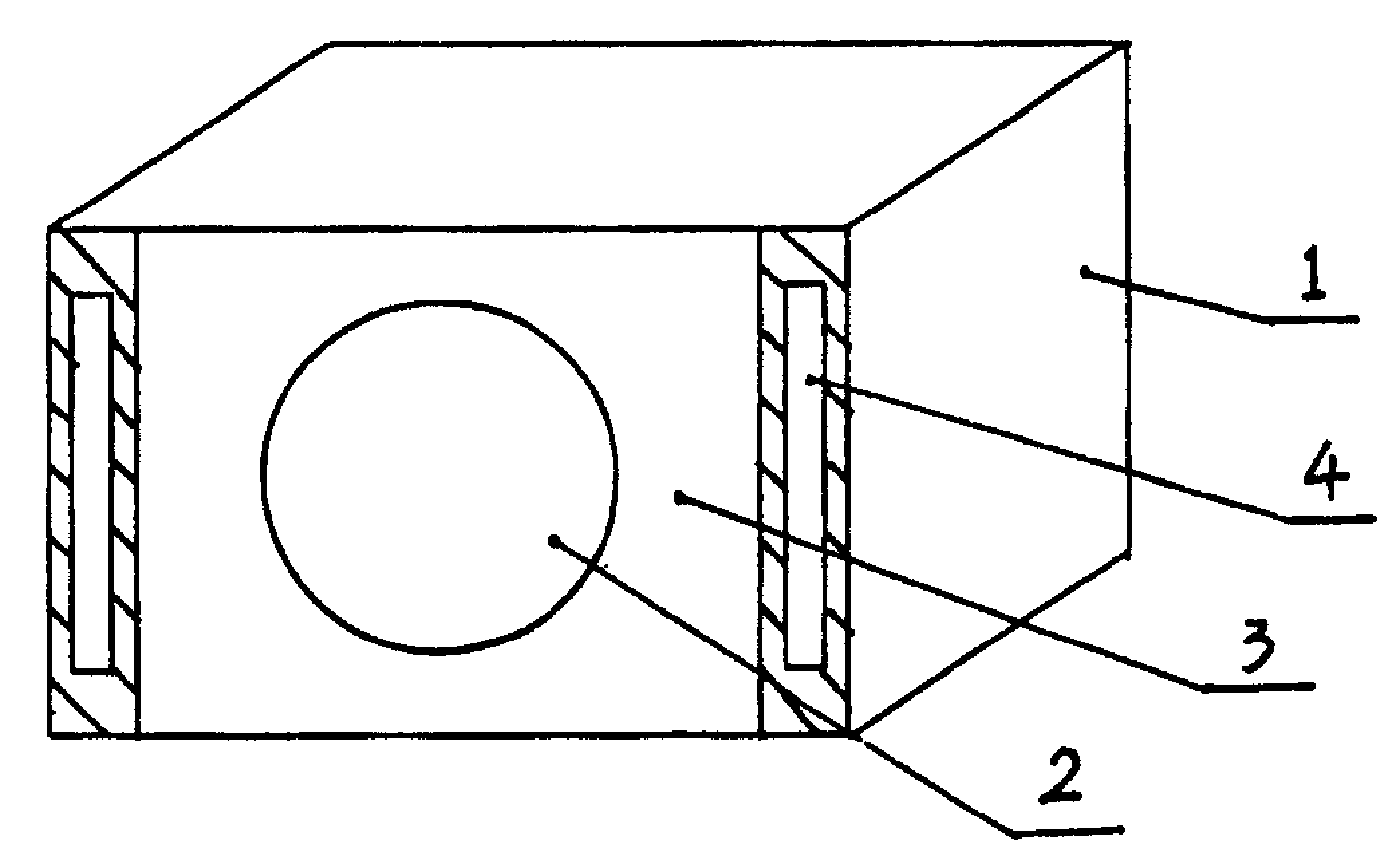

[0034] figure 1, figure 2 It is an embodiment applied to No. 3 generator of Guangdong Shajiao Power Plant A. As can be seen from Fig. 1, the monitoring device in this embodiment is composed of a pressure sensor 2 and an insulating box 1, the pressure sensor 2 is built in the insulating box 1, and the insulating box 1 is made of epoxy resin, and a cylindrical cavity is arranged in the box. The cavity and the sensor are placed in the cavity, and a metal shielding layer 3 is arranged on the sensor 2, and the sensor 2 and the shielding layer 3 are cured into a whole with epoxy resin; grooves 4 are arranged on the outside of the insulating box 1, and the sensor 2 The signal output end of the signal is drawn out of the insulation box 1 through the shielded cable; through the groove 4, the insulation box 1 with the sensor 2 is bound to the outlet nose of the stator winding to be measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com