Button top, button switch part and manufacture thereof

A technology of switch parts and top parts, applied in the direction of electric switches, electrical components, legends, etc., can solve the problem of not being able to provide key top components, and achieve the effect of eliminating the damage of visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

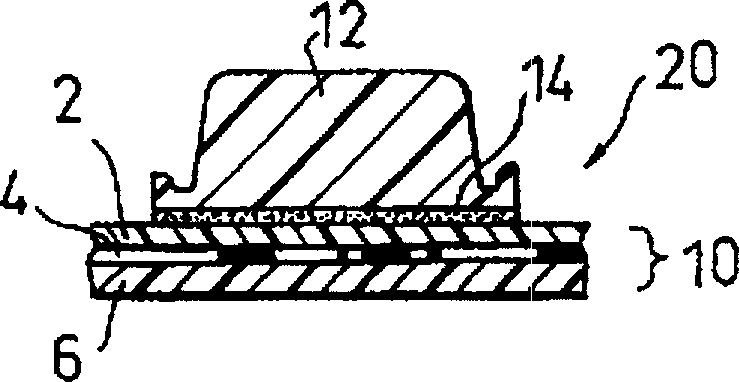

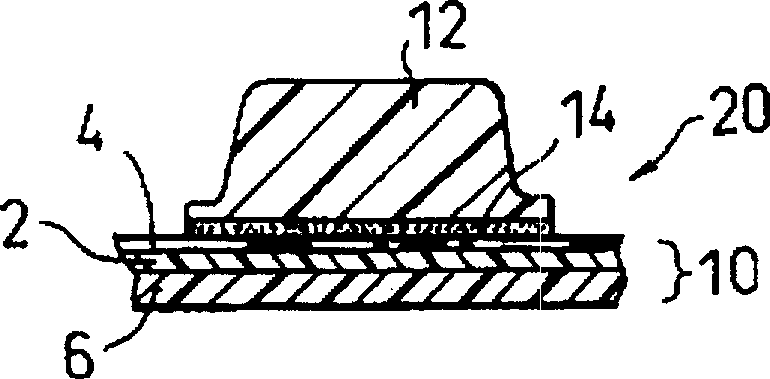

[0141] On a transparent polyester sheet having a thickness of 125 μm, color symbols and color symbols as a design of the key top were printed on a transparent polyester sheet having a thickness of 125 μm with a thermal conduction sublimation type printer purchased from Victor Co. of Japan, Ltd. under the trade name "Trueprint-3500". Geometric patterns. Color symbols and geometric patterns are designed with a microcomputer.

[0142] Then, a translucent white polyester having a thickness of 25 µm was laminated on the back surface of the polyester sheet thus printed to form a white layer, constituting a printed sheet.

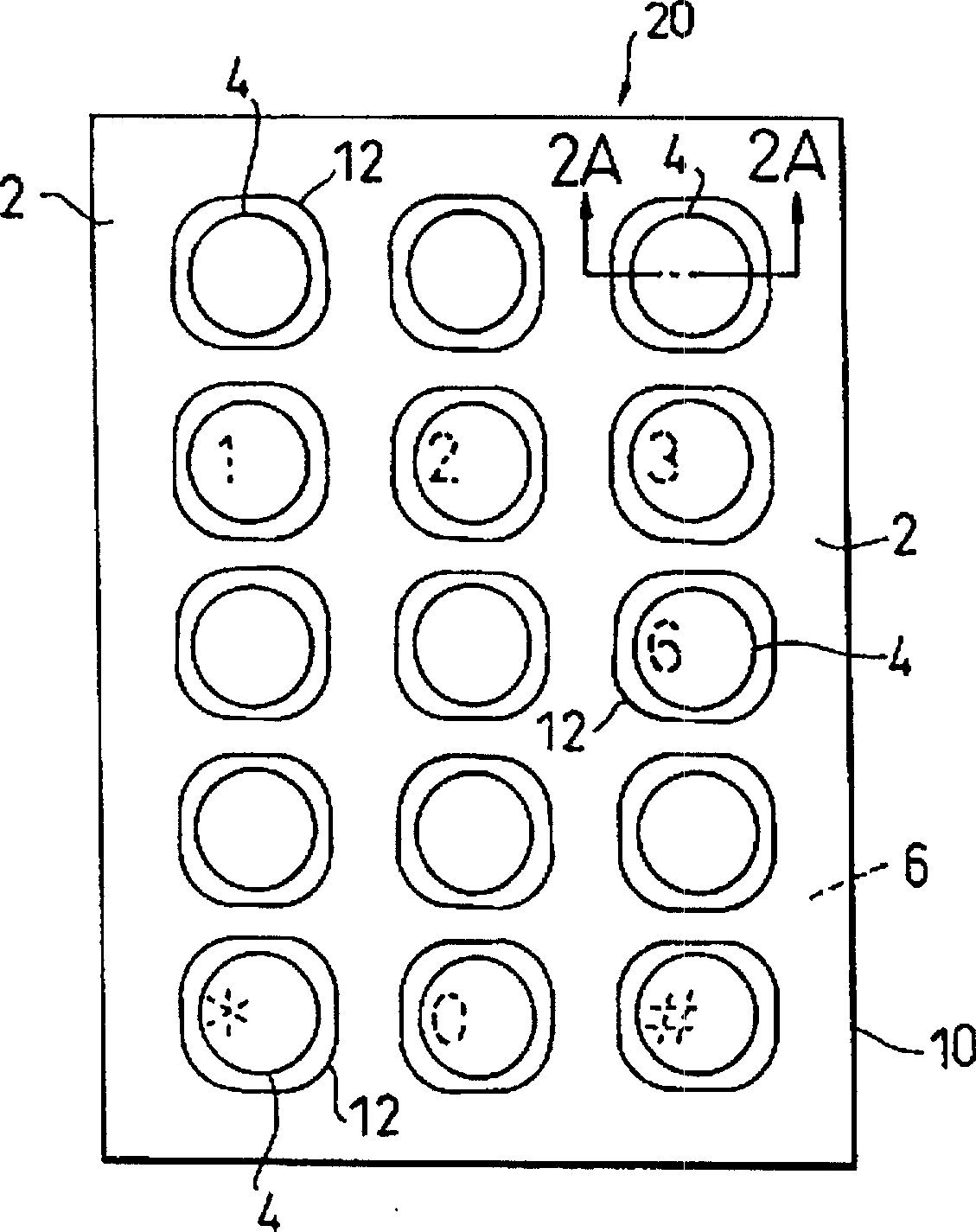

[0143] Next, the transparent key top member was formed from a thermoplastic polypropylene resin material to have a predetermined configuration by means of an injection molding machine. A keytop member was prepared by fixedly mounting twenty of these transparent keytop members on a printed sheet using a transparent polyester adhesive available from Hitachi Kasei P...

example 2

[0145] On a transparent polyester sheet having a thickness of 125 μm, color markings or symbols of a design as key top members and Geometric patterns, thereby preparing printed sheets of key tops. The code and geometric patterns are designed with a microcomputer.

[0146] An aluminum film was then deposited by hot embossing on a rear surface of the thus formed printed sheet to provide a silver colored layer.

[0147] Then, a photolithographic polypropylene resin material commercially available from Mitsubishi Rayon Co., Ltd. under the trademark DIABEAM UT-1022 was cast using a pre-configured mold, and then irradiated with ultraviolet rays, thereby A transparent key top element is formed.

[0148] The transparent key top elements are then bonded to the printed sheet by heating with the aid of a transparent silicone adhesive commercially available from Shin-Etsu Chemical Co., Ltd. under the trade mark KE-1934 to produce key tops. pieces.

example 3

[0150] A printed sheet of a key top was prepared by printing color symbols and geometric patterns as the design of the key top on a transparent polyester sheet by means of an electrostatic transfer printer. Such an electrostatic transfer printer is commercially available from Canon Corporation under the trademark NEW PIXEL Dio 950. Color symbols and geometric patterns are designed with a microcomputer.

[0151] Then, a translucent white polyester sheet was laminated on a rear surface of the above polyester sheet to provide a printed sheet.

[0152] Next, a thermoplastic polypropylene resin material is formed into a predetermined configuration of the transparent key top member by means of an injection molding machine, and the member is bonded or connected to the printed sheet, thereby producing the key top member.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap