Connector for module

A connector and connection state technology, applied in the direction of connection, two-part connection device, parts of connection device, etc., can solve problems such as unstable operation of semiconductor memory, poor contact of modules, plastic deformation of wrist, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 6 Embodiment

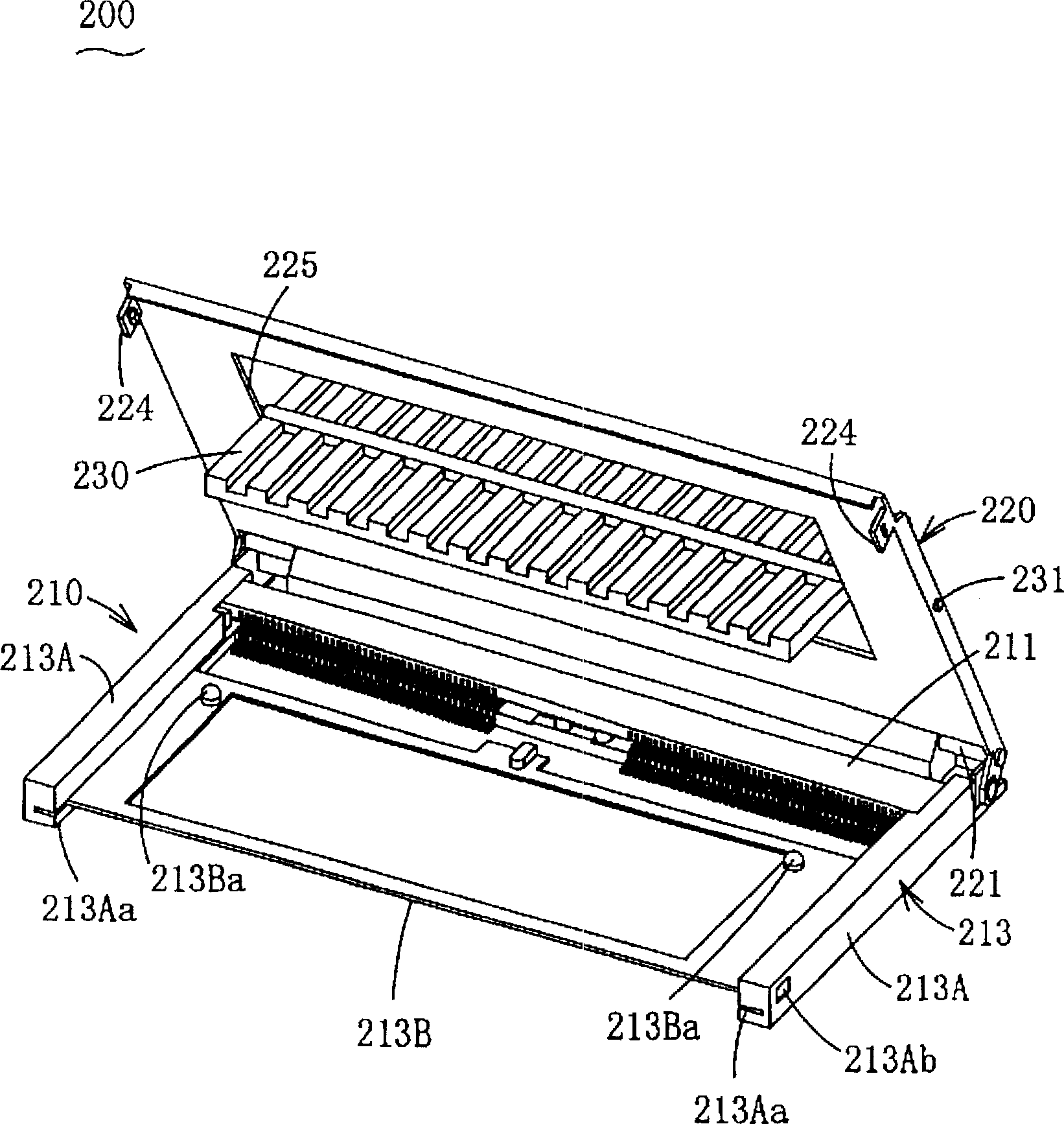

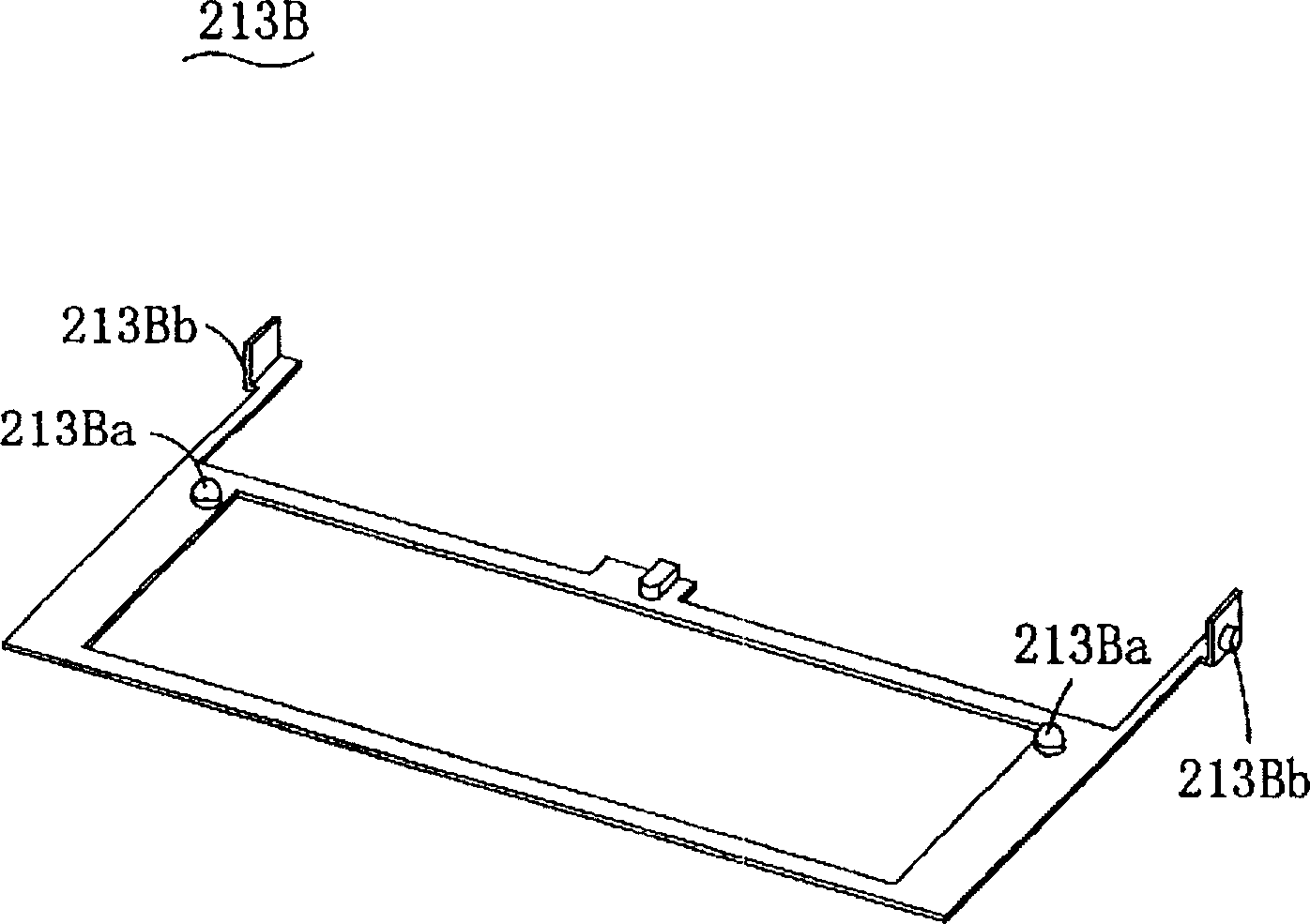

[0075] In the sixth embodiment, there is an embodiment in which the present invention is applied to a connector at a portion not linked to the lifting and lowering of the rear end of the metal cover 220 of the supporting portion 213, and the same operations and effects as those in the first embodiment can be obtained.

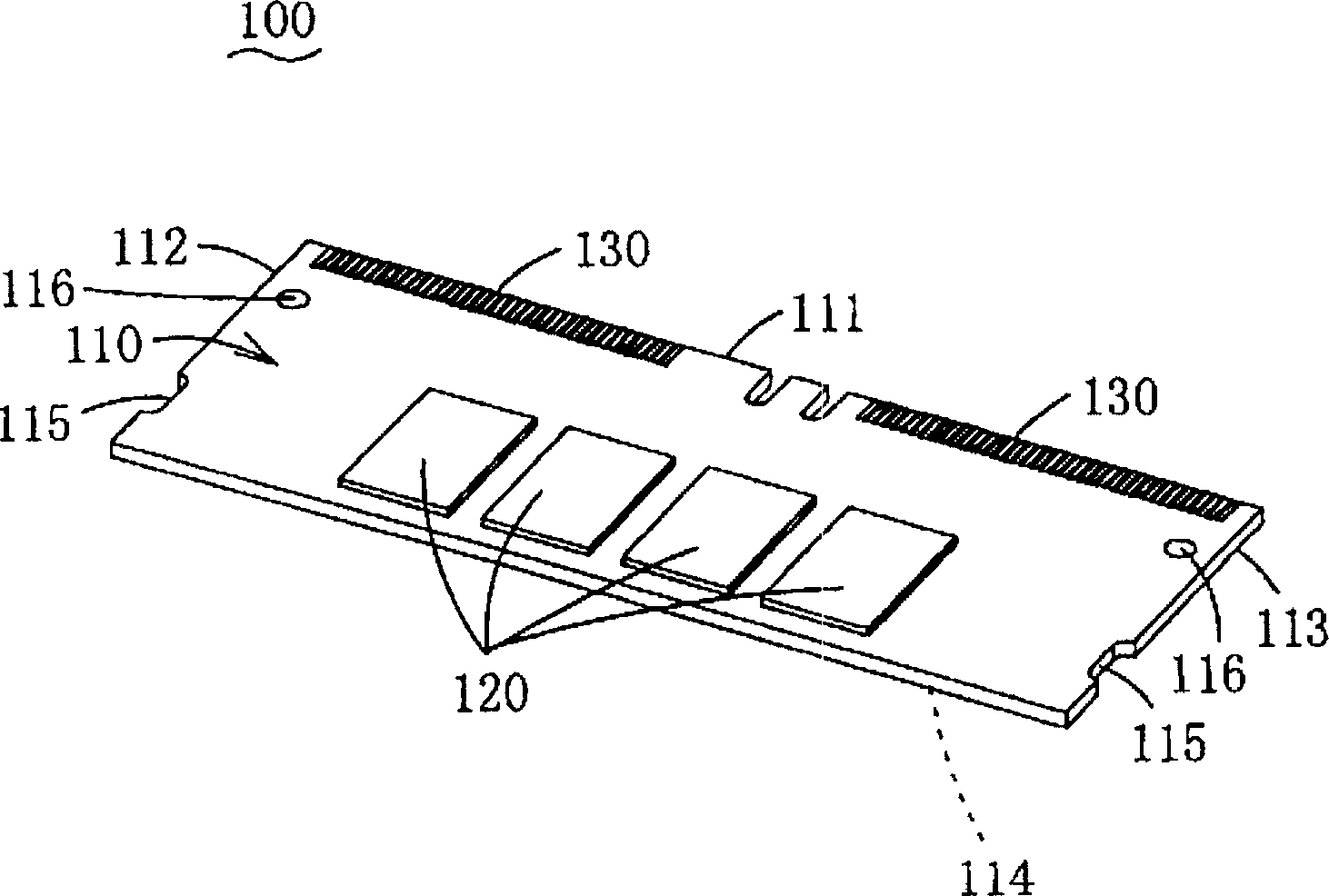

[0076] 35 to 37B show the seventh embodiment. In the seventh embodiment, there is no movable part that slides on the support part 213 as in the sixth embodiment, and there is no part in the support part 213 that is interlocked with the raising and lowering of the rear end of the metal cover 220 . Furthermore, the metal cover 220 is not hingedly coupled to the access portion 211 , and is designed to be freely attachable to and detachable from the connector body 210 . In the support piece 228 hanging down from the left end side and the right end side of the metal cover 220, an inverted L-shaped guide groove 228a is formed at the lower end. In addition, the conne...

Embodiment 7

[0079] In Embodiment 7, the metal cover 220 is not hingedly combined with the access portion 211. In the embodiment in which the connector body 210 is set to be freely detachable, regardless of the application of the present invention, the same result as in Embodiment 1 can be obtained. role and effect. In addition, when the metal cover 22 is removed, the contacts 212a and 212b are exposed and can be easily recognized by the eyes, so that the insertion operation of the substrate 110 is facilitated.

[0080] FIG. 38 shows Embodiment 8. FIG. In Example 8, with figure 1 In the same embodiment, the metal cover 220 is hingedly combined with the access portion 211 . Furthermore, the metal cover 220 is detachably attached to the connector body 210 by separating this hinge structure. On the left and right sides of the insertion portion 211, there are provided contact walls 260 protruding upward. Here, the receiving wall 260 is provided with a receiving hole 261 penetrating in the ...

Embodiment 8

[0082] In Embodiment 8, the metal cover 220 is not hingedly combined with the access portion 211. In the embodiment in which the connector body 210 is set to be freely removable, regardless of the application of the present invention, the same result as in Embodiment 1 can be obtained. role and effect. In addition, removing the metal cover 220 exposes the contacts 212a and 212b and makes them easy to recognize with the eyes, so that the insertion operation of the substrate 110 is facilitated.

[0083] The present invention includes embodiments combining the features of the above embodiments.

[0084] Through the description of these embodiments, the first module connector mentioned in the outline of the present invention has been fully disclosed. Moreover, the connectors for the second and third modules described below have been fully described by the description of these embodiments.

[0085] That is, in the connector for the second module, in the connector for the first mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com