Method for making ferrite stainless steel seamless pipes and cold working process thereof

A manufacturing method, a stainless steel technology, is applied in the manufacture of ferritic stainless steel pipes and small-diameter ferritic stainless steel seamless pipes. The effect of technological progress, avoiding intergranular corrosion problems, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] Below in conjunction with preferred embodiments, the specific implementation, features and effects provided by the present invention are described in detail as follows; for the purpose of simplicity and clarity, the description of known technologies is appropriately omitted below to avoid unnecessary details Affect the description of this technical solution.

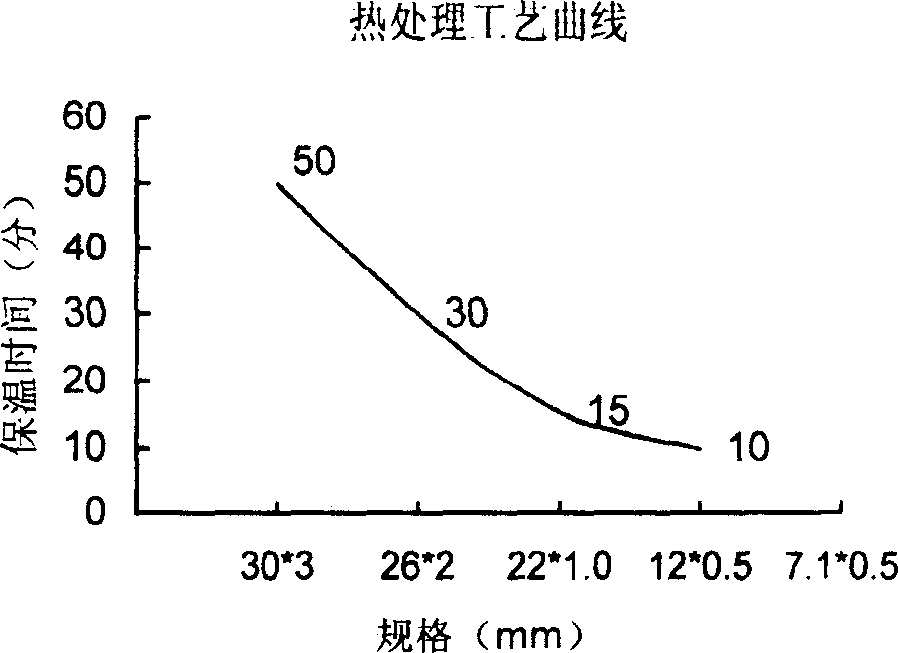

[0086] Manufacture an AISI446 ferritic stainless steel seamless pipe, the specification is Φ6.3×0.3mm, the outer diameter is ±0.1mm, the wall thickness is 0.3-0.35mm, and the length is 58.5±0.1mm; performance requirements: HV<200 during deep processing Cracks are not allowed, and the extension after processing is consistent.

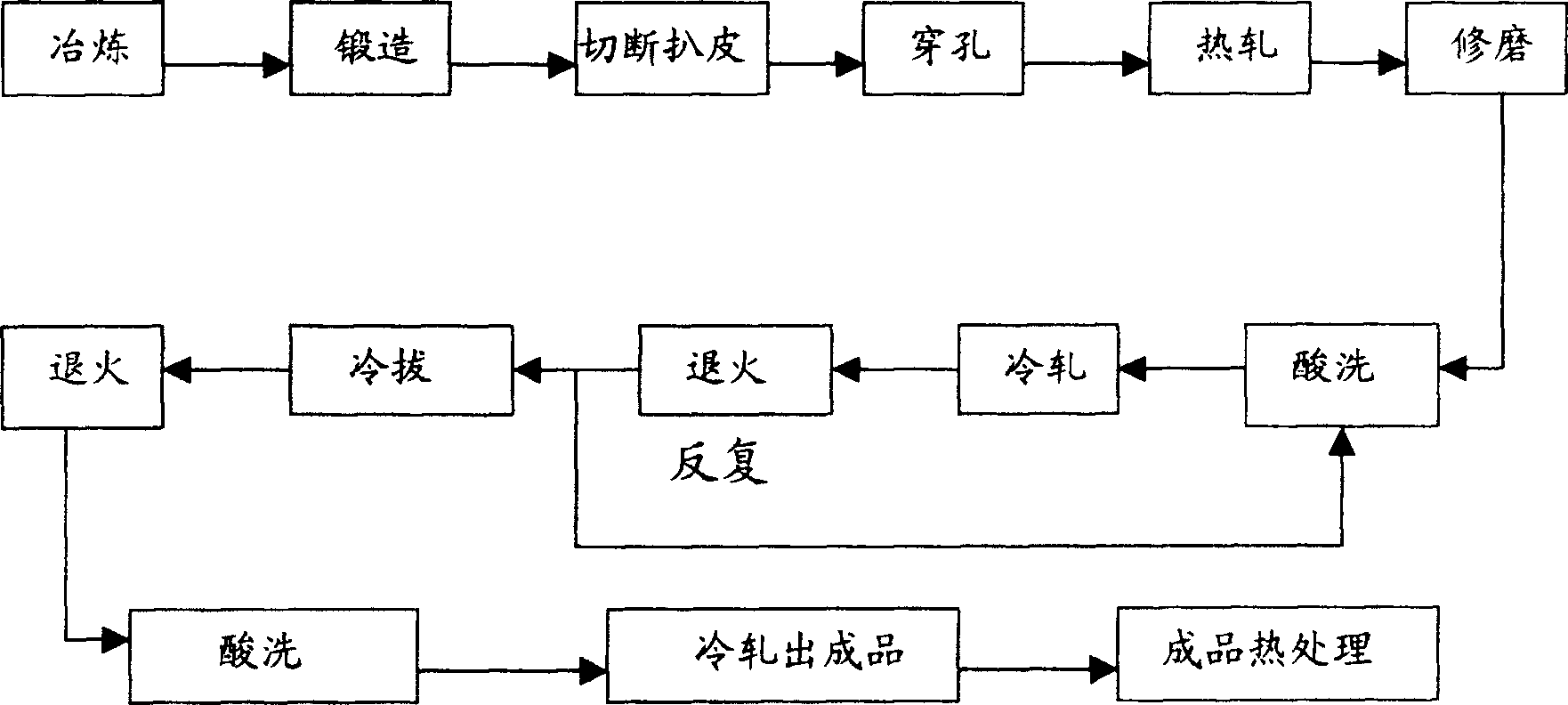

[0087] A method for manufacturing a ferritic stainless steel seamless pipe, comprising the following steps:

[0088] I. The smelting process adopts a vacuum induction furnace with a vacuum degree of 10 -3 Torr, steel ingots can be smelted, and can also be smelted by VOD method;

[0089] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com