Fire-retardant polymer composition

A technology of polymer and composition, applied in the direction of aluminum compounds, cables, insulated conductors, etc., can solve the problems of insufficient mechanical properties of the mixture, large amount of addition, difficulty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The specific surface area is about 3m 2 A filter cake of finely crystallized aluminum hydroxide per g and a residual moisture of about 50% by weight was introduced to the milling and drying unit with conventional conveying equipment. The amount of solid matter introduced was 200 kg / h. The hot air is introduced, and the inlet temperature of the hot air is 270-290°C. The air input volume is 5000Bm 3 / h. The peripheral speed of the drum was 80 m / s. The dried product is separated by a filter of sufficient size and taken out through a rotary valve.

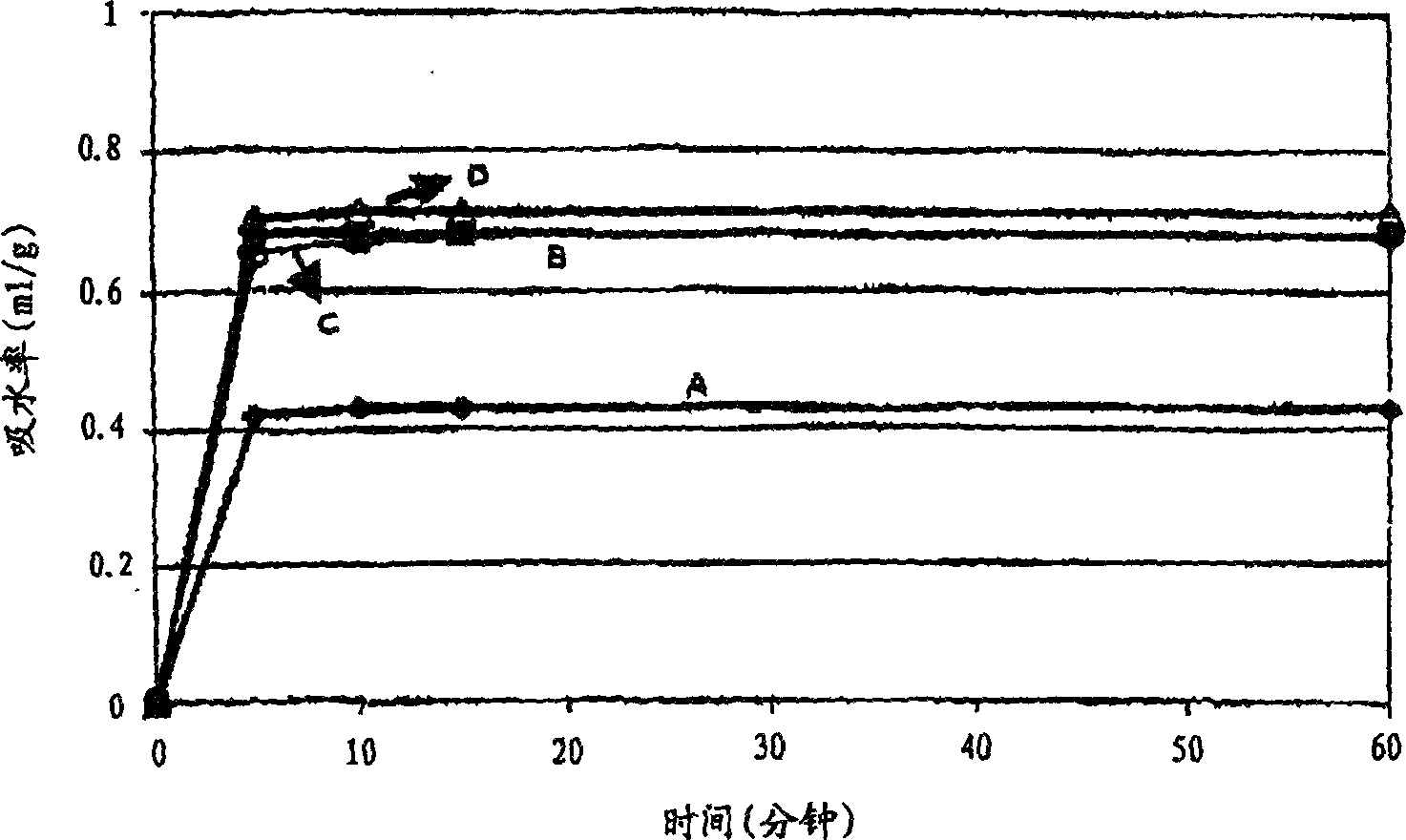

[0063] Table 1) summarizes the most important properties of the powders obtained as above and compares them with three commercially available flame retardants based on ultrafine aluminum hydroxide. Comparative product B was based on the same leach-wet ultrafine hydroxide as product A of the invention. As can be seen from the data in Table 1, the ratio of the BET of the product A of the present invention to the BET of the c...

Embodiment 2

[0071] The specific surface area is about 5m 2 A finely crystalline aluminum hydroxide filter cake with a residual moisture of about 53% by weight and a residual moisture of about 53% by weight was introduced into the grinding drying unit with conventional conveying equipment. The amount of solids introduced was 200 kg / h. Inlet hot air, the inlet temperature of hot air is 250-280℃, and the air input volume is 5000Bm 3 / h. Rotary drum speed is 2000-3000rpm. The dried product is separated by a filter of adequate size and discharged through a rotary valve.

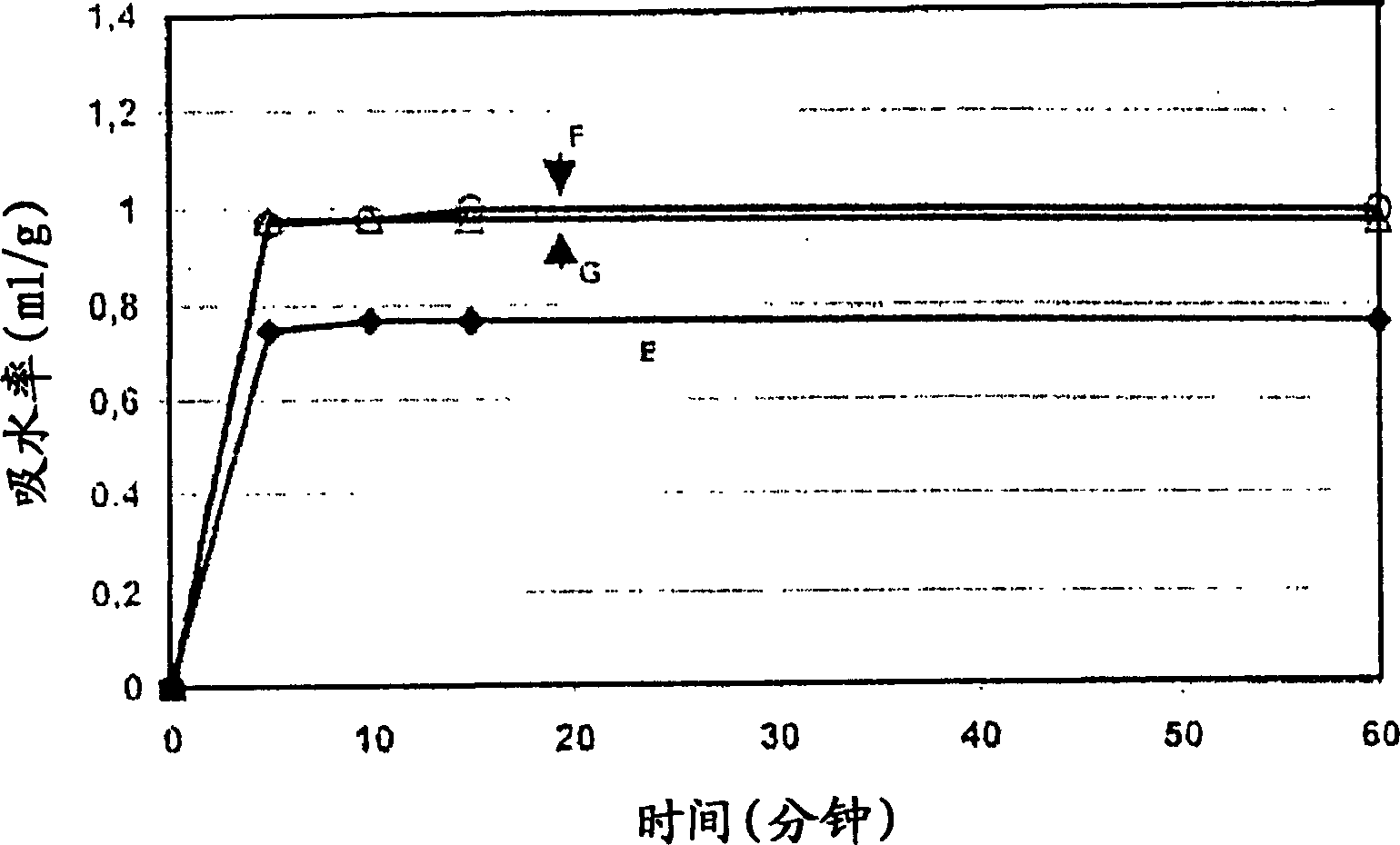

[0072] Table 2) summarizes the most important properties of the powder E obtained as above and compares it with the commercially available product F. At the same time, Table 2) also includes data for Product G based on the same leached-moist ultrafine hydroxide as used for the preparation of Product E according to the invention, but prepared according to a process based on commercially available Product F of.

[0073] A...

Embodiment 3

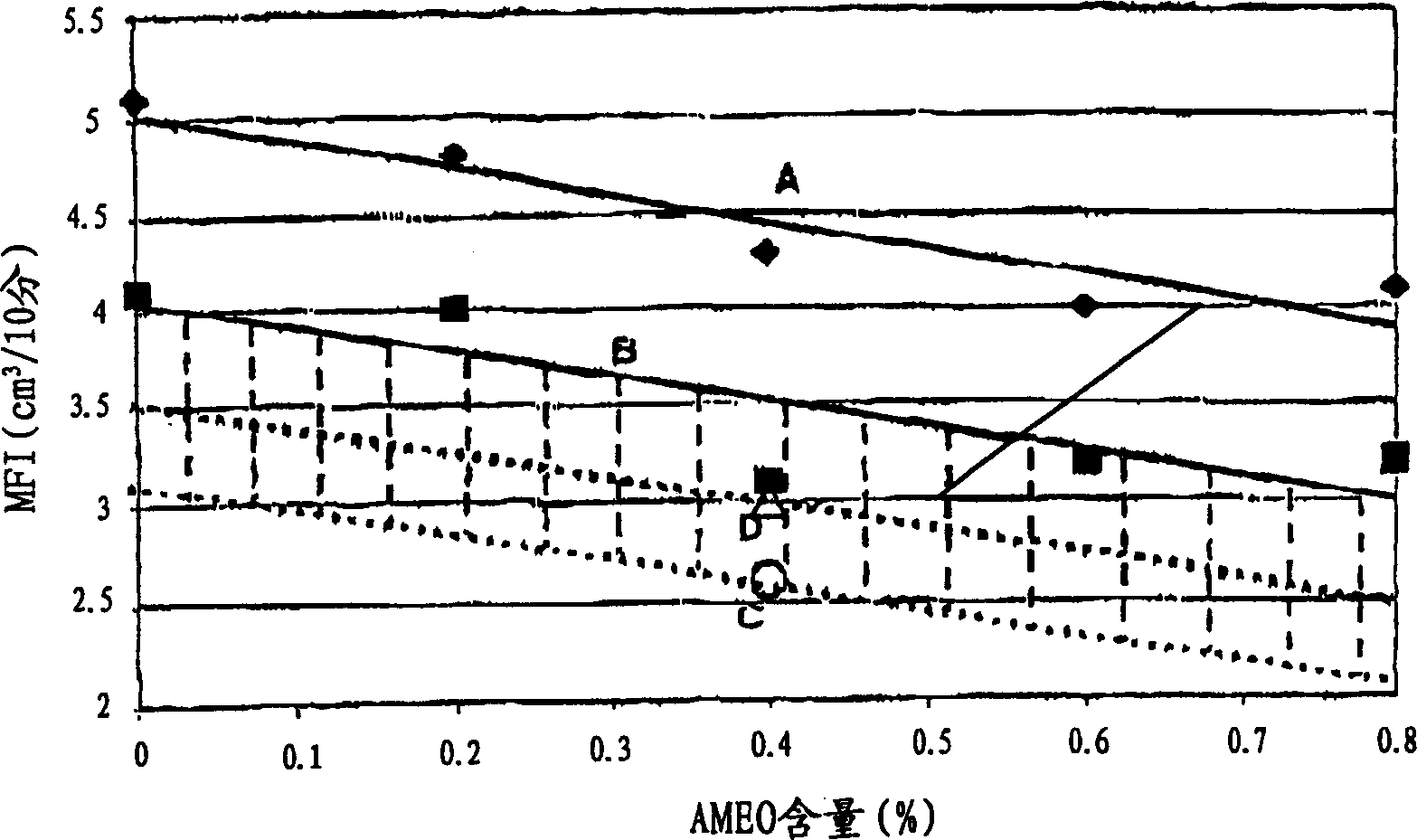

[0076] Product A of the present invention and comparative products B, C and D were all mixed with an unsaturated polyester resin Palapreg P17 (manufactured by BASF AG). The filler was added with a mixer type IKA-RE166. The same amount of Palapreg P17 resin and filler was added within 3 minutes at 3500 rpm, followed by a further 2 minutes of stirring at 5500 rpm, resulting in a finely divided mixture with a filler content of 50% by weight. The obtained filled resin was kept at 22° C. for 2 hours, and then the viscosity was measured with a Brookfield RVT viscometer at a rotation speed of 20 rpm (using a No. 6 spindle). The results are compared in Table 3).

[0077] flame retardant

[0078] Viscosity is lowest when product A is used. When using products B and C, the viscosity is three times that of product A. When using product D, because the viscosity is too high, the instrument used cannot be measured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com