Technique of accurate micropores film for filterning salt water in use for making alkali

A microporous and process technology, which is applied in the field of precision microporous thin-layer filtration technology, can solve the problems of deterioration of filtration performance, low average filtration rate, and increase in operating costs, and achieve the prolongation of the average filtration rate decline process, reduction of filtration resistance, Effect of Filtration Efficiency Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

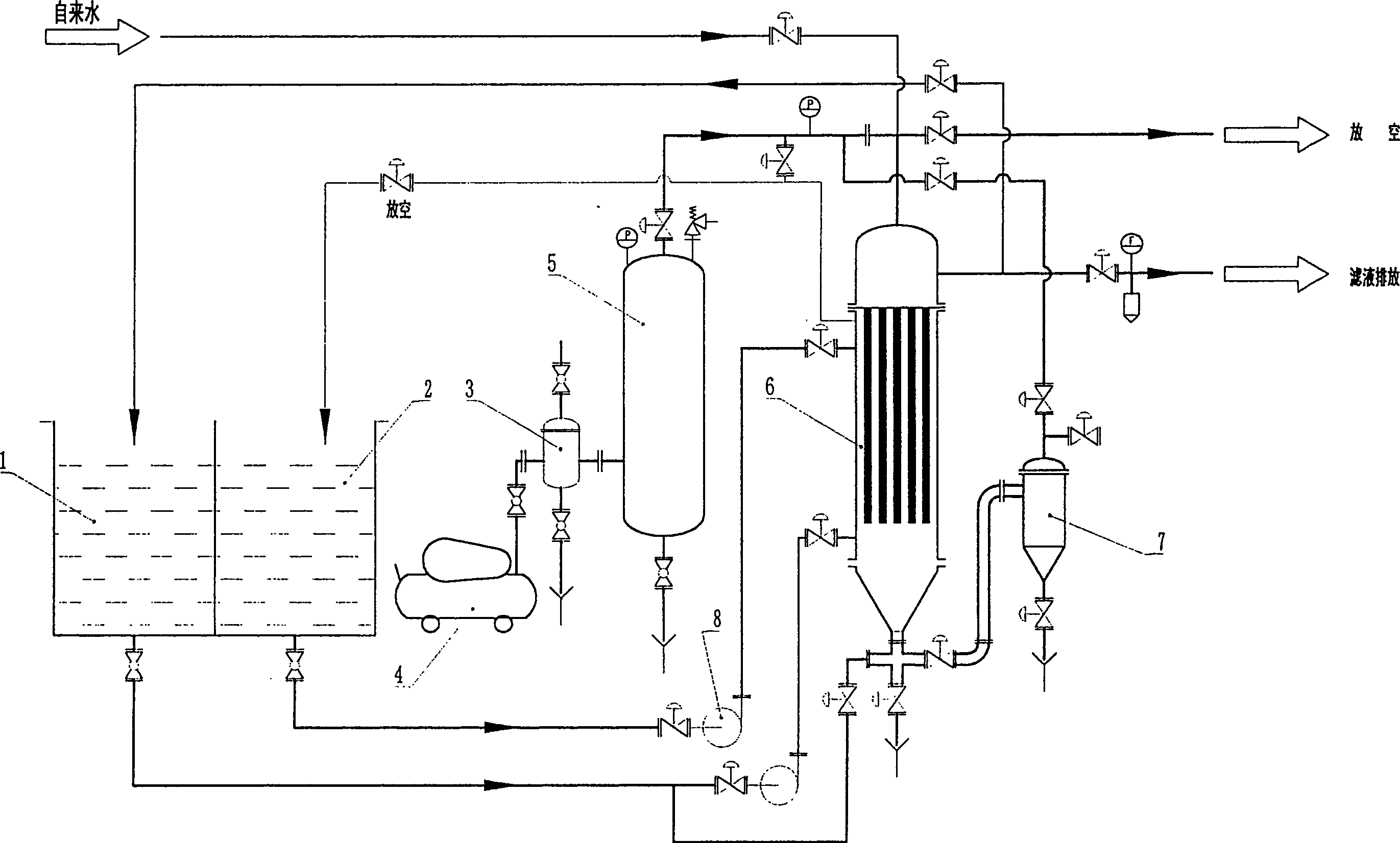

[0016] like figure 1 As shown, the precision microporous thin-layer filtration process of salt water used in alkali production in the embodiment of the present invention includes the following devices: regeneration liquid storage tank 1, brine stock solution storage tank 2, air filter 3, air compressor 4, compressed air storage tank 5 , Precision microporous filter 6, thickened filter residue storage tank 7, centrifugal pump 8, and PLC interlocking full automatic control device. The precision microporous filter 6 is the main equipment of this process. It consists of three parts. The upper part is a cylindrical shell with an elliptical arc-shaped head, which is used as an intermediate storage room for filtrate or compressed air; the middle part is a cylindrical shell. The upper and middle shells are connected by a pair of flanges, and a porous flower plate is sandwiched between the upper and lower flanges. The rigid sintered microporous filter tube is fixedly connected to the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com