Pollen spore wall breaking machine

A wall breaking machine and pollen technology, which is applied in application, food preparation, grain processing, etc., can solve the problems of complexity, cost, and unsatisfactory effects, and achieve the effects of improving taste, increasing sweetness, and reducing processing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] best practice

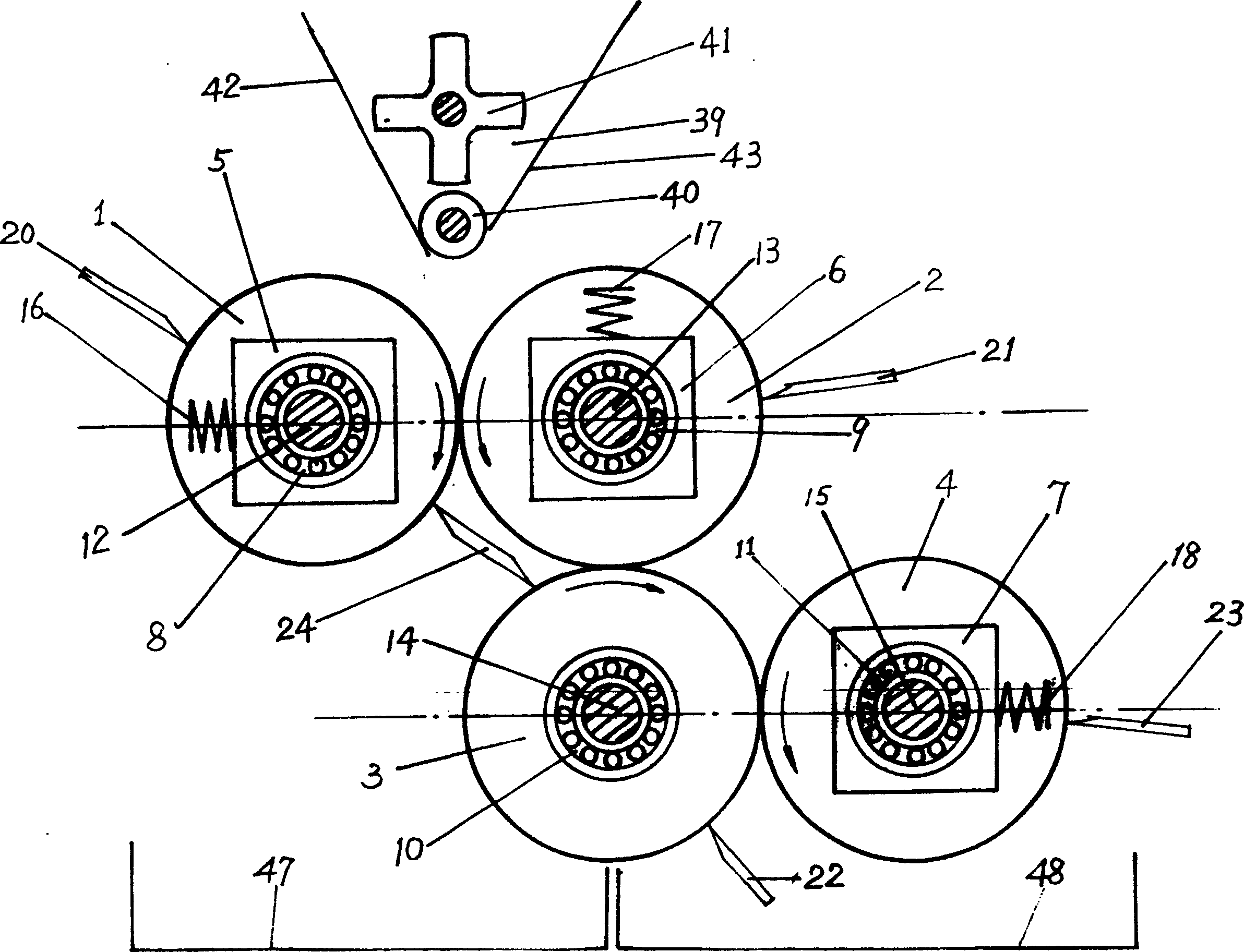

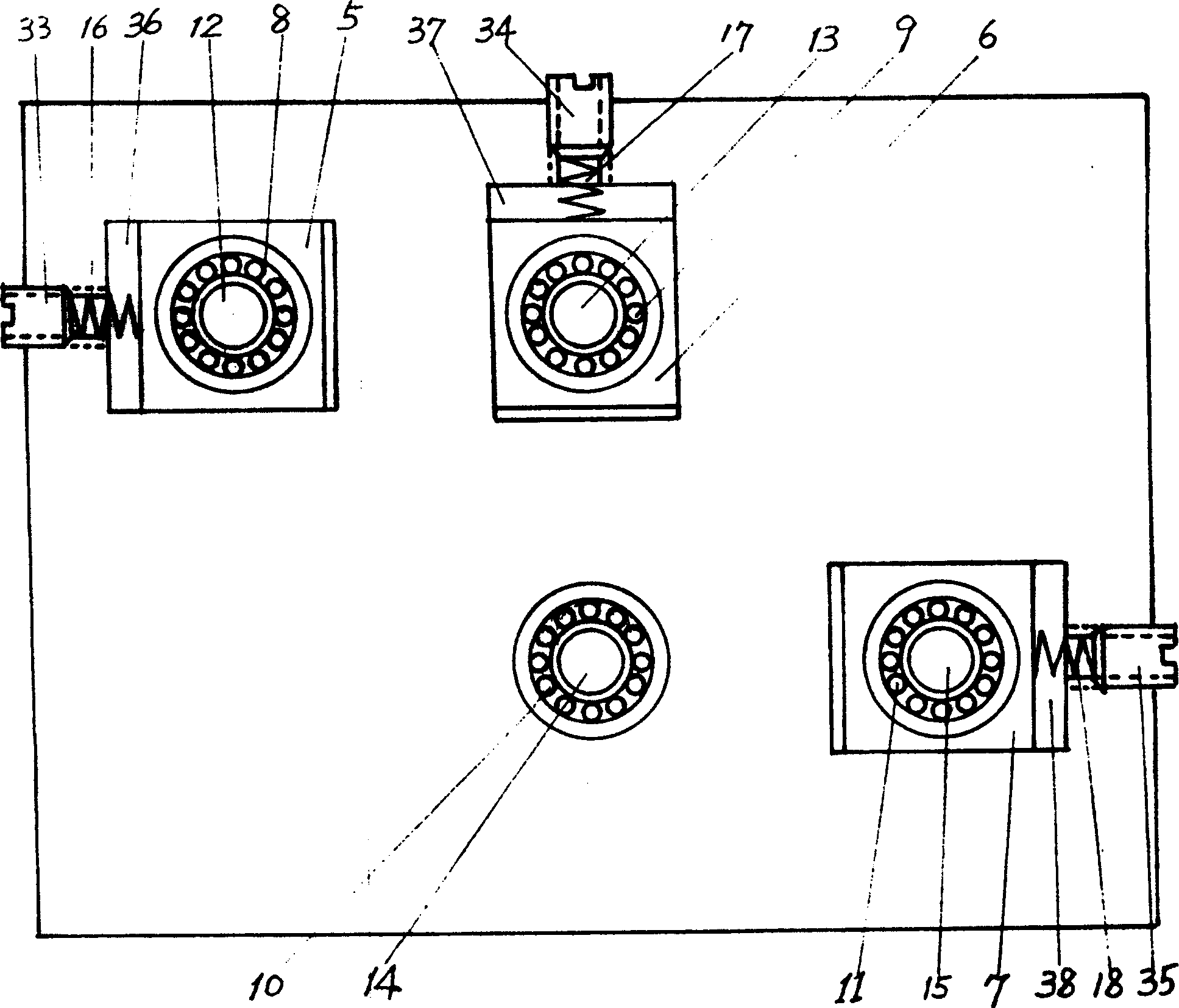

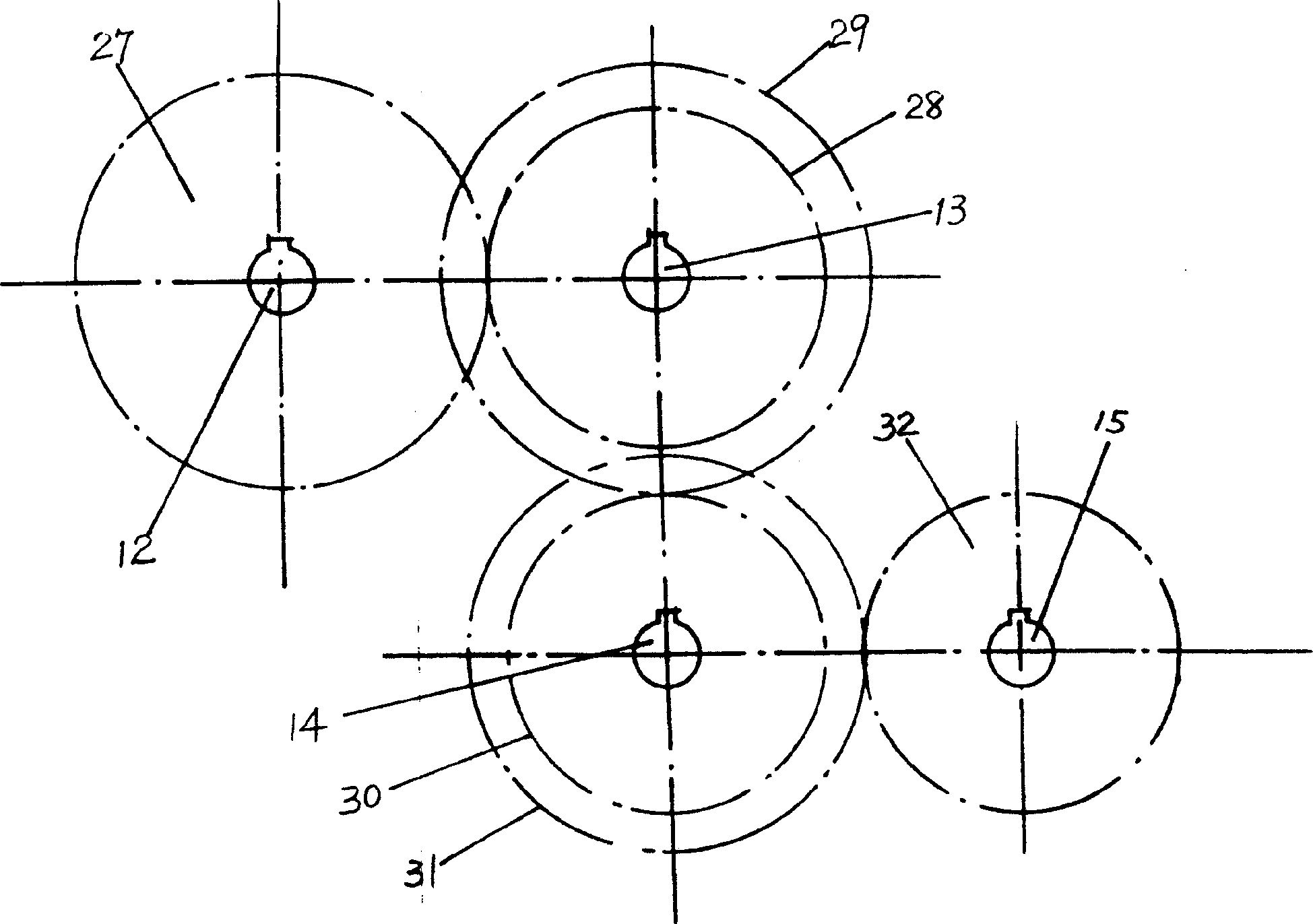

[0014] The preferred embodiment is described below with reference to illustrations. The four-roller wall breaking machine is mainly composed of rolls (1, 2, 3, 4), sliding bearing housings (5, 6, 7), springs (16, 17, 18, 19), front support plates (25), rear support Plate (26), gear (27,28,29,30,31,32), double-edged scraper (24), single-edged scraper (20,21,22,23) and waterfall type lower hopper (39) form.

[0015] The parts mounted on the front support plate (25) in the present embodiment comprise sliding bearing housings, springs, adjustment screws, ball bearings and the like parts mounted on the rear support plate (26) are paired. Because except adjusting screw, these parts that are contained on the rear support plate all do not draw, therefore also include the corresponding parts on the rear support plate (26) whenever referring to these parts in the following description. The present embodiment is described below by system.

[0016] Roll system. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com