Flexible tactile sensor and method for detecting infomation of tactile sensation

A tactile sensor, sensor technology, applied in manipulators, manufacturing tools, etc., can solve the problems of large size, inflexibility, low spatial resolution, etc., to achieve reliable contact and grasping process, increase contact area, and avoid damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

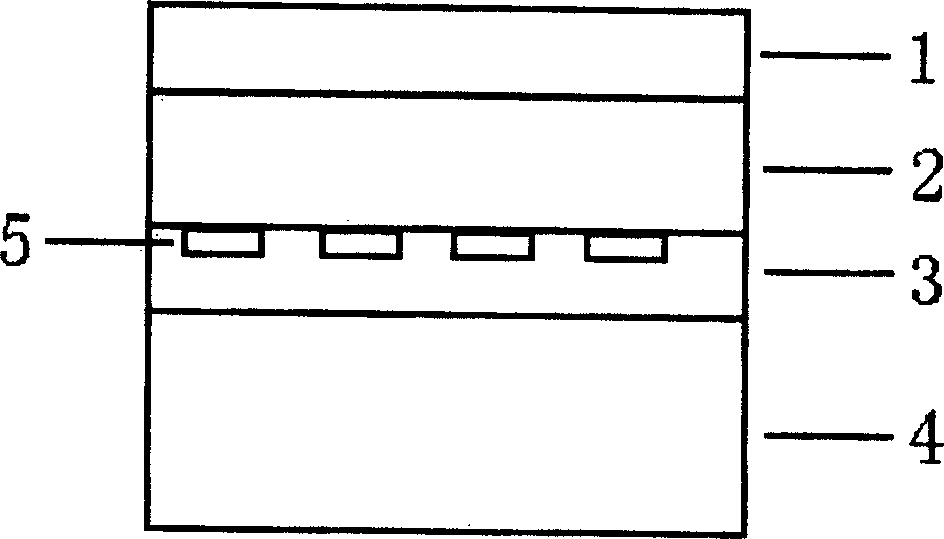

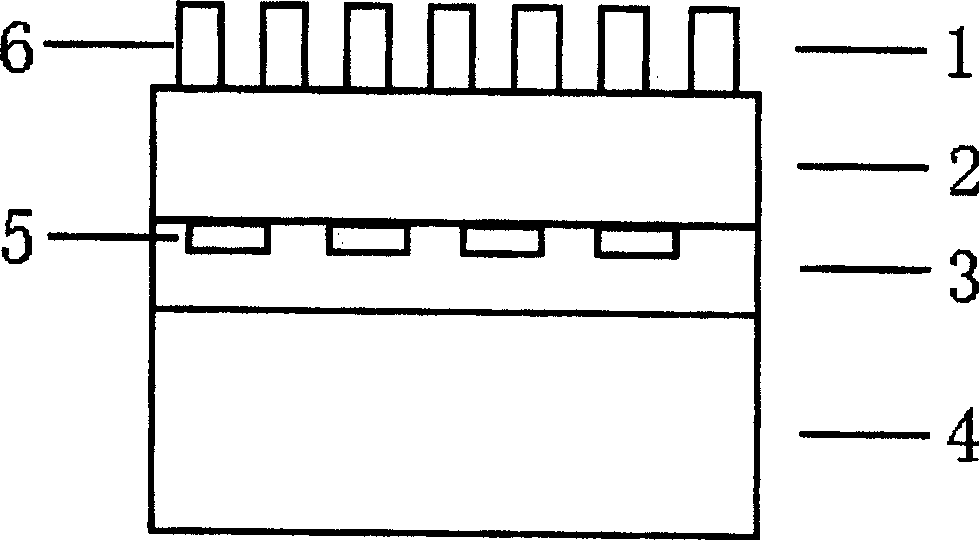

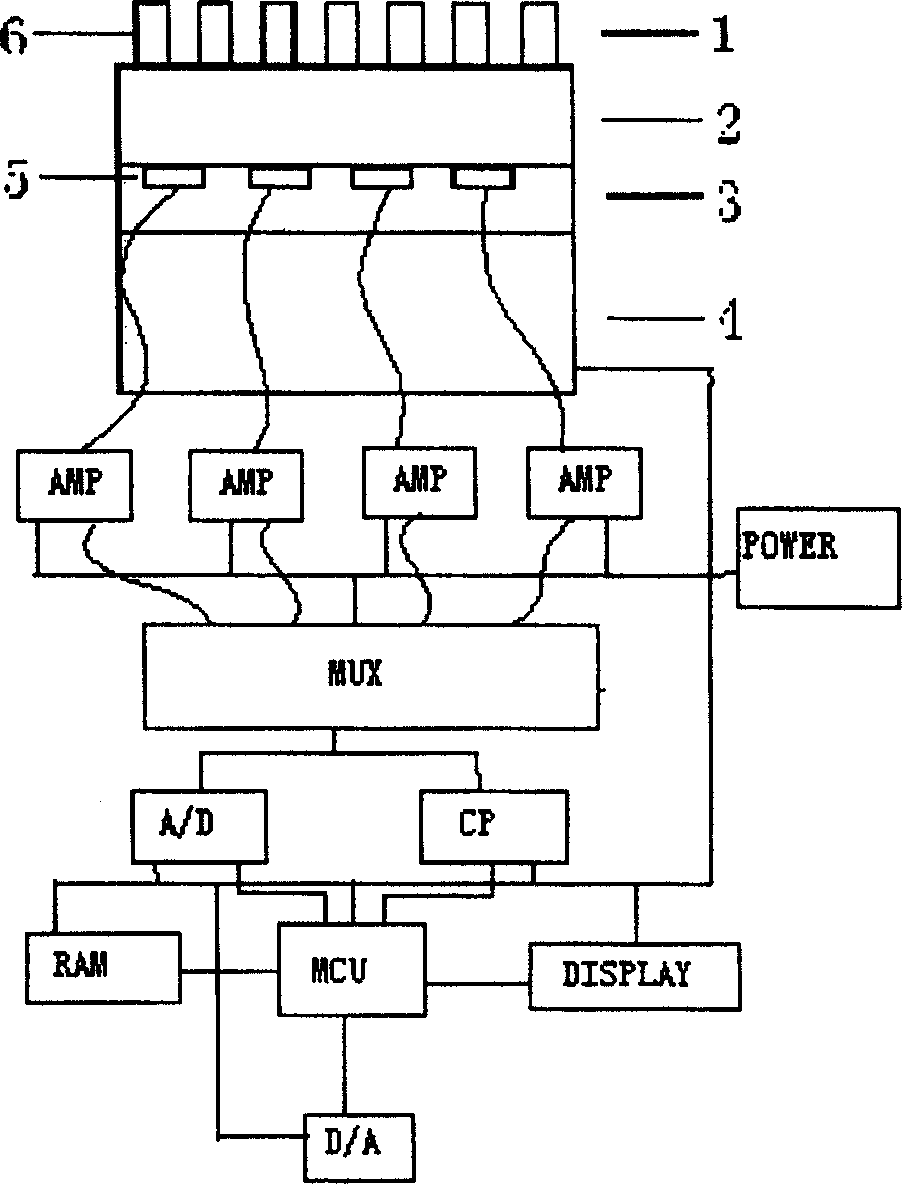

[0066] The flexible tactile sensor proposed by the present invention is composed of two parts: a sensor probe and a signal processing circuit. There are two structures of the sensor probe, which are shown in figure 1 and figure 2. Both sensor probes mainly include magnetic rubber 1 , elastic interlayer 2 , magnetic sensitive array 3 and glass substrate 4 . The magnetic rubber 1 is located on the outermost layer of the sensor probe, and it is directly in contact with the measured object as a working surface. There are no electronic devices and electrodes on the working surface of the magnetic rubber 1, so there will be no possible damage to electronic devices and their circuits due to contacting and grabbing the target object, so the reliability is better. Below the magnetic rubber 1 is an elastic interlayer 2, which is a buffer layer between the magnetic rubber 1 and the magnetic sensitive array 3. Both the magnetic rubber 1 and the elastic interlayer 2 are flexible mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com