Expanding metal material and bulged tube device for petroleum oil well

A technology of expanding alloy and expanding pipe, applied in the direction of pipe elements, wellbore/well parts, pipes/pipe joints/pipe fittings, etc., which can solve the problems of unstable expansion operation, insufficient external pressure strength, and difficult processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] The expansion tube device of the present invention is as Figure 4 As shown, it includes guide head 1, lower sealing cone 2, fixed nut 3, warhead piston 4, lower expansion tube 5, fixed ring 6, centralizer 7, shape memory joint 8, sealing ring 9, upper expansion tube 10, rubber Ring 11, positioning ring 12, positioning cylinder 13, hydraulic pipe 14, return spring 15, hydraulic anchor 16, load-bearing calipers 17 and heater 18 constitute.

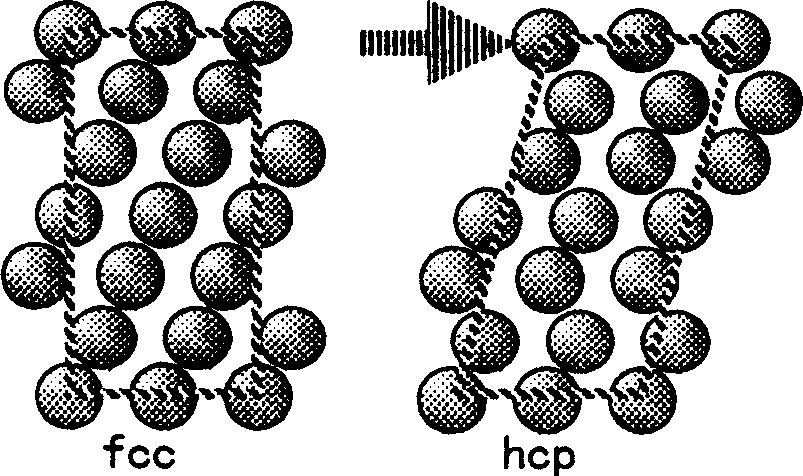

[0024] The expansion tube series is formed by connecting several expansion tubes, wherein between the lower expansion tube 5 and the adjacent upper expansion tube 10 or between other expansion tubes and the expansion tubes, shape memory joints (iron-based shape memory alloys, for example, chemical weight percent Composition: C 0.045, Mn 27.8, Cr 4.98, Si 5.21, P 0.02, S 0.02, balance is Fe)8 connection, see Figure 4 Enlarged view on the right. When the shape memory joint is connected, it is embedded in the annular groove formed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com