Air foil configuration for wind turbine

A wind turbine and airfoil technology, applied in the field of airfoil structure, can solve the problem of non-optimization of the composite airfoil and achieve good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0106] As above, using the formula:

[0107] (Formula 16)

[0108] to derive the maximum aerodynamic criterion for the optimal airfoil.

[0109] where Equation 16 can be used to calculate the rotor size for a 15% load reduction. For example, taking Tackes' TW1.5s turbine with a 70.5m rotor and a 1500KW rated power, it can be determined that the load will be reduced by 15% when the blade stiffness is halved. The rotor can then be scaled up according to the following formulas, derived from Equation 16:

[0110] (M 额定 ) 较大的,可变的 =(M 额定 ) 基准,可变的 (R 较大的 / R 基准 ) 5 / 3 =.85(M 额定 ) 基准 (R 较大的 / R 基准 ) 5 / 3 =(M 额定 ) 基准 (Formula 17)

[0111] And, in order to find the diameter of the new rotor, we can get:

[0112] R 较大的 / R 基准 =(1 / .85) / 6=1.10 (Equation 18)

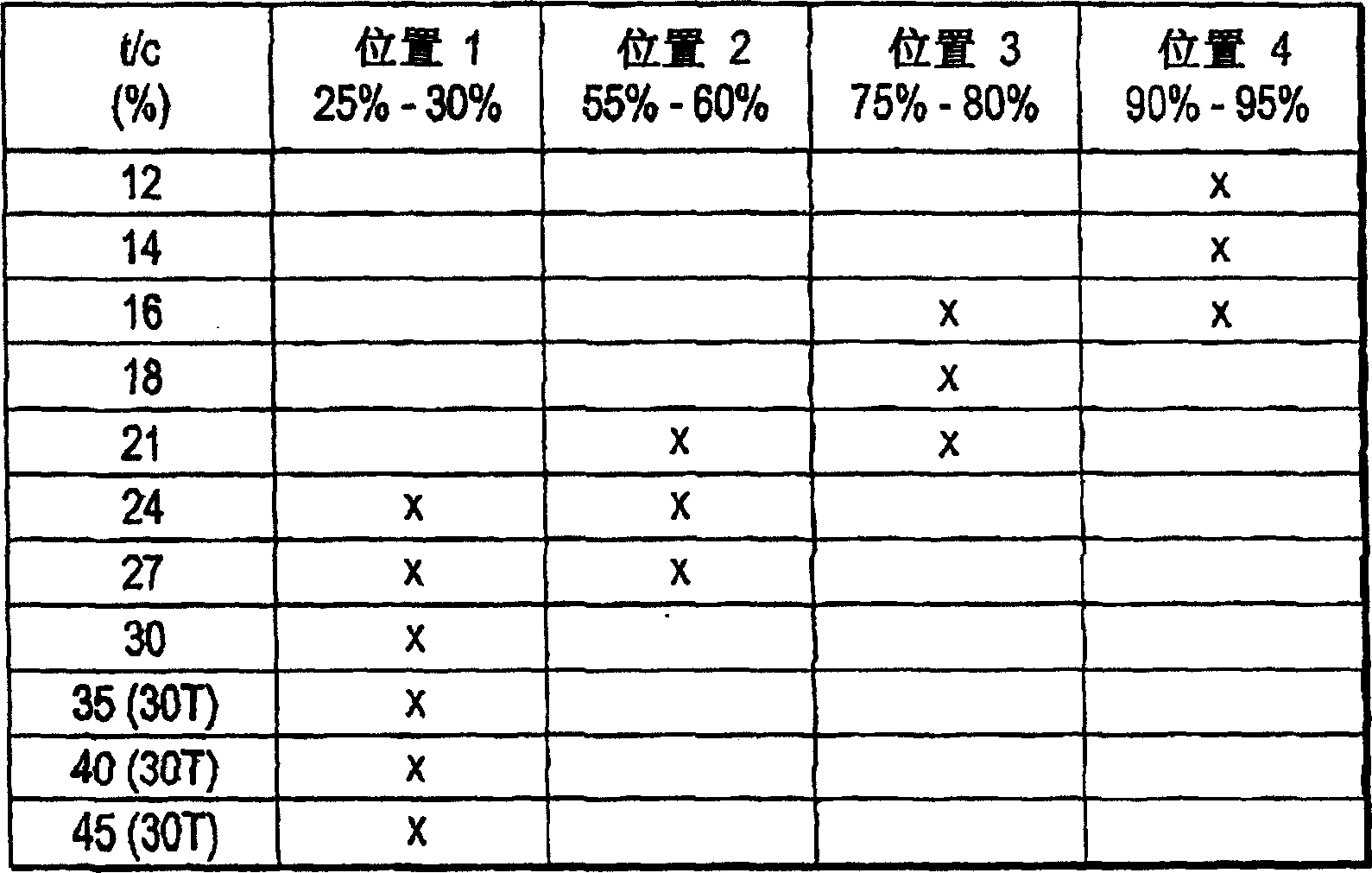

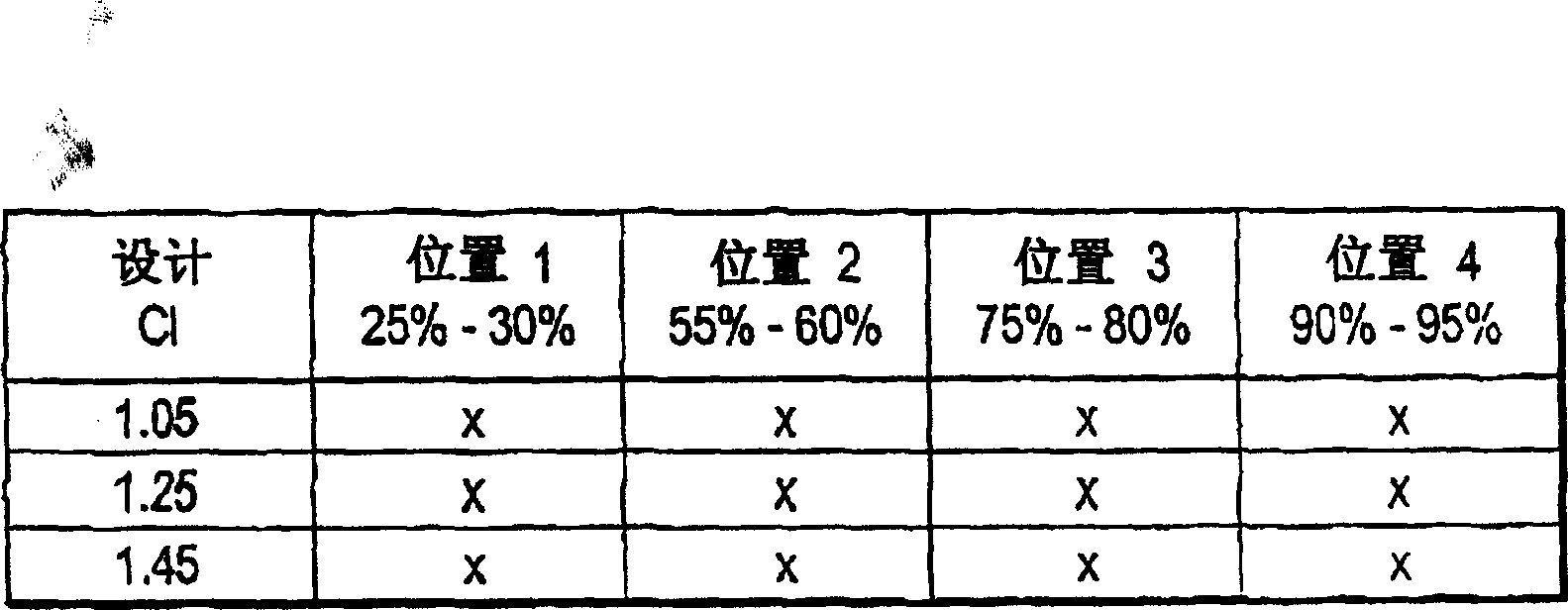

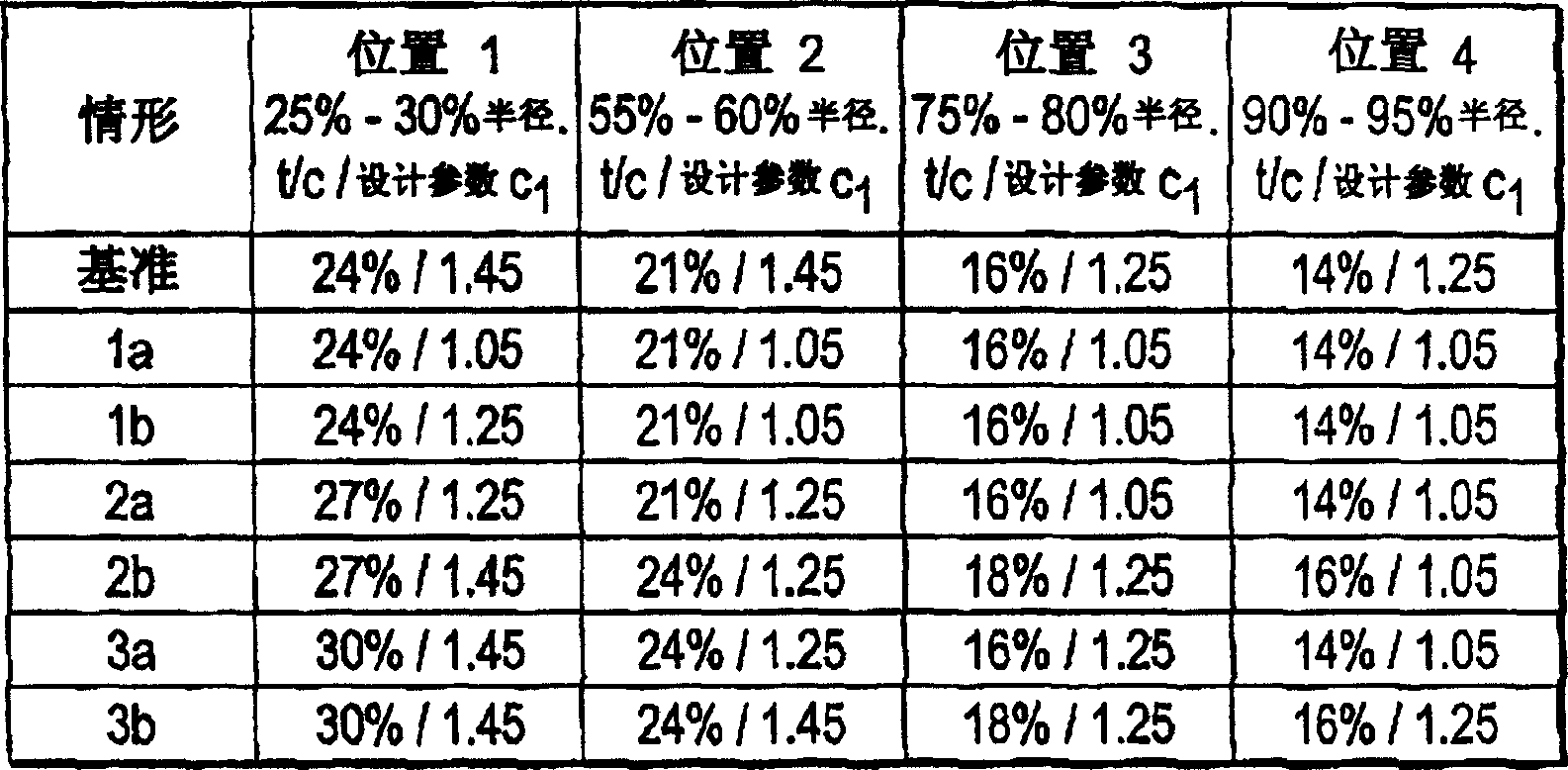

[0113] Once completed, the example Figure 1-13 Modifications to the design are made based on the graph information collected in identifying the structural features to modify the opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com