Method for making titanium cathode roller member

A manufacturing method and cathode roller technology, applied in the direction of electrodes, electrolysis process, electroforming, etc., can solve the problems of ring rolling and spinning difficulties, high production cost, large-scale special equipment, etc., and achieve a wide range of applicable specifications, low cost, high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

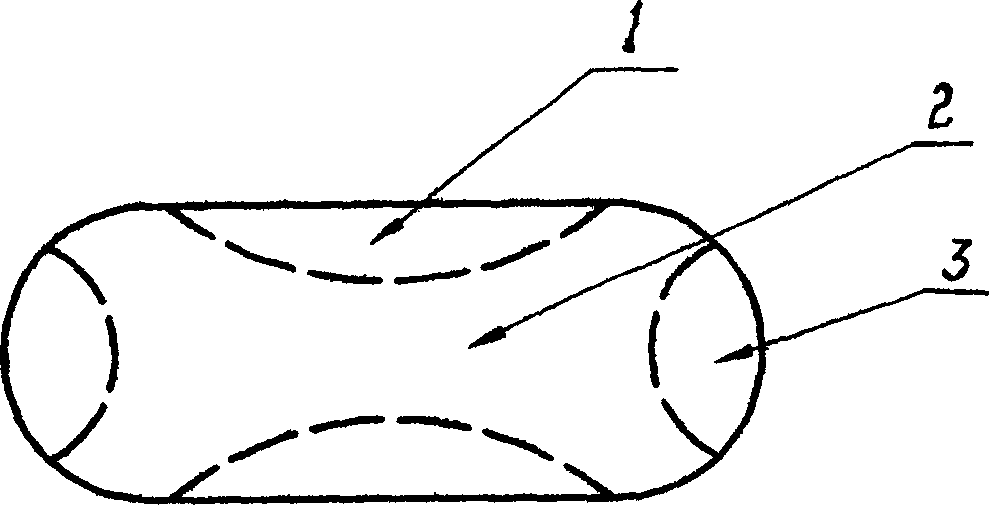

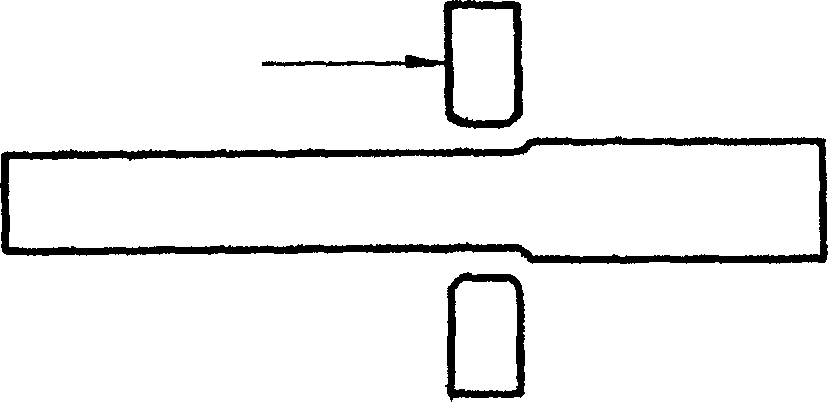

[0014] combined with figure 1 , 2 , 3 describe an embodiment of the present invention.

[0015] 1. First roll the titanium plate into a cylinder and weld the seams, and check the quality of the welds.

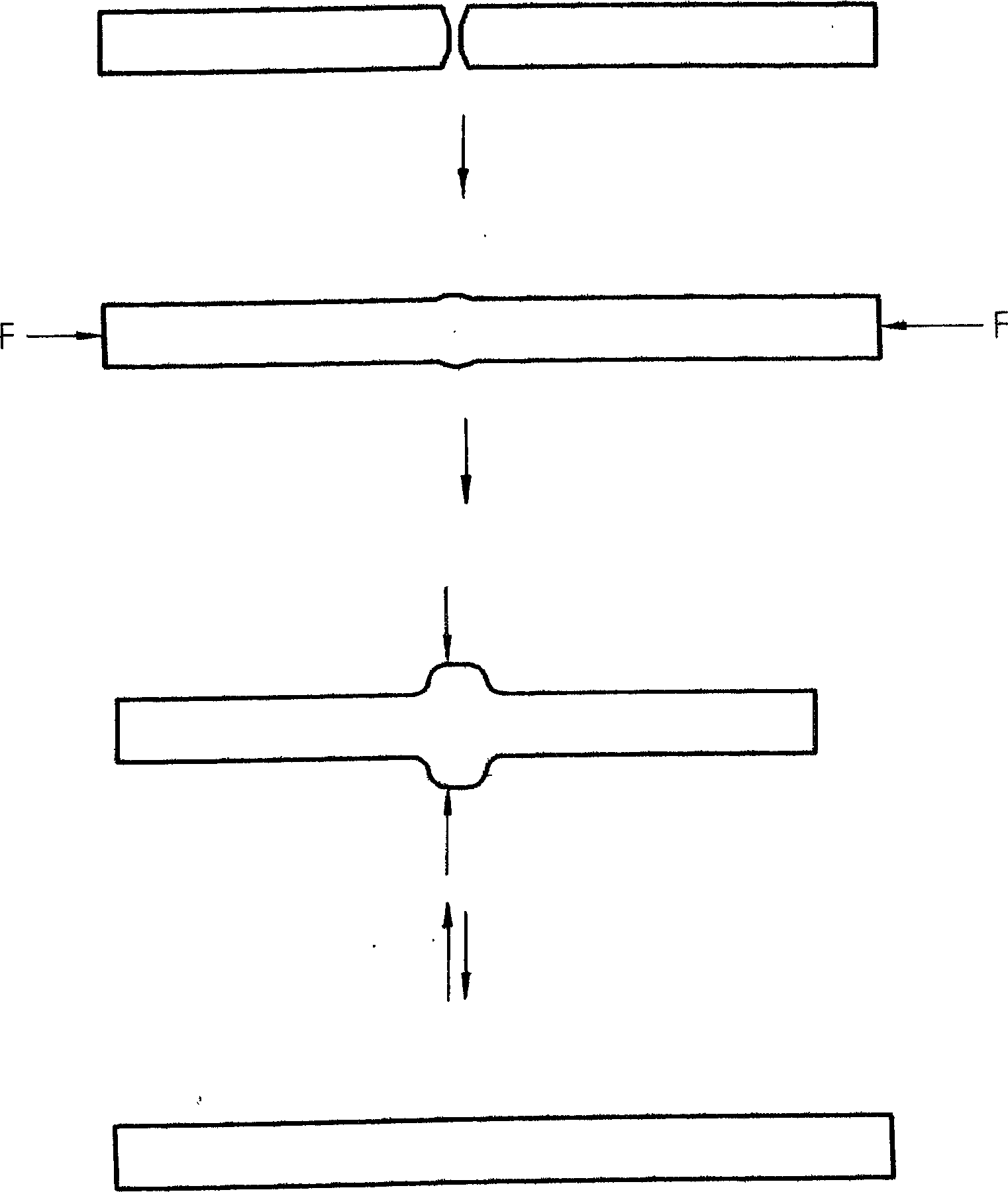

[0016] 2. For the first heating of the weld seam and the heat-affected zone, the temperature is controlled at about 900°C, and the non-deformable base material part should be cooled and protected to prevent the temperature of the non-deformable zone from exceeding 30°C under the phase transition point; Upsetting the welding seam, and then forging the upsetting part flat, and each time the deformation should be about 50%. The upsetting part is usually forged with a gradual deformation method, that is, a small feed is used, and each feed is controlled at Between 10 and 30mm.

[0017] 3. Carry out the second heating on the weld seam and the heat-affected zone, the temperature is controlled at about 850 °C, and the non-deformable base material part should be cooled and protected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com