Processing photographic materials and processing system therefor

A photographic material and system technology, applied in silver salt photosensitive material technology, photosensitive material, nuclear engineering, etc., can solve the problems of reducing stains, stain-removing agents are not very soluble in developing solutions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

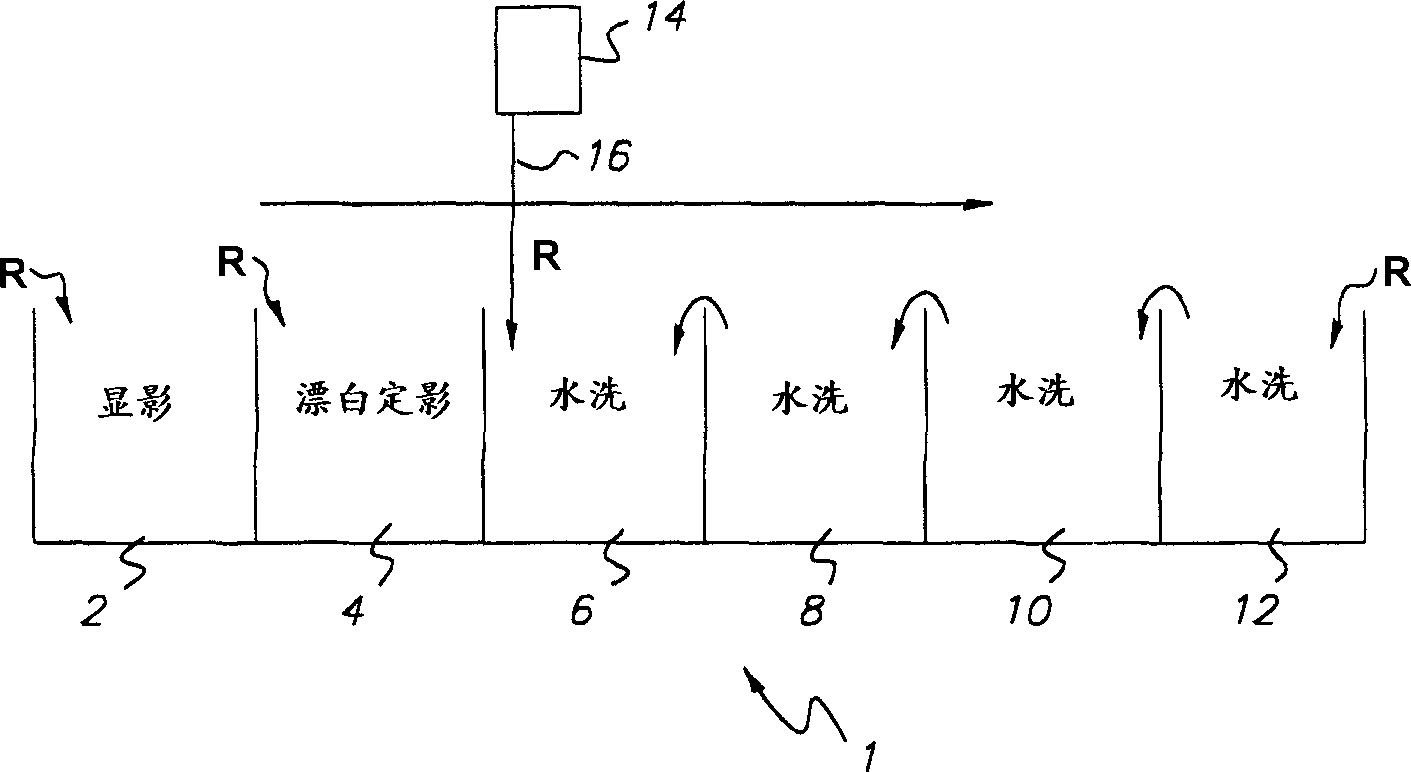

[0027] Table 1

[0028] Short processing cycle (seconds) temperature (°C)

[0029] Develop 15 40

[0030] Bleach-fix 15 40

[0031] Washing for the first time 5~20 37

[0032] Main wash 15 37

[0033] The developer used is Kodak (registered trademark) Ekta Color SM (registered trademark) developer, and Kodak Ekta Color SM bleach solution (pH 6.3) for bleaching and fixing. The photo paper used is Ekta Color Edge7. The first water wash included 2g / l and 8g / l water check solution and Phorwite REU solution. Phorwite REU is an optical brightener. The reference machining cycle is shown in Table 2.

[0034] Table 2

[0035] Long processing cycle (seconds) temperature (°C)

[0036] Development 45 37.8

[0037] Bleaching-fixing 45 37.8

[0038] Washed 90 35

[0039] The developer used is Kodak (registered trademark) RA-12 developer, bleach-fixing Kodak RA-12 bleach solution. This process gave reference values for CIELAB smear measurements for Koda...

Embodiment 2

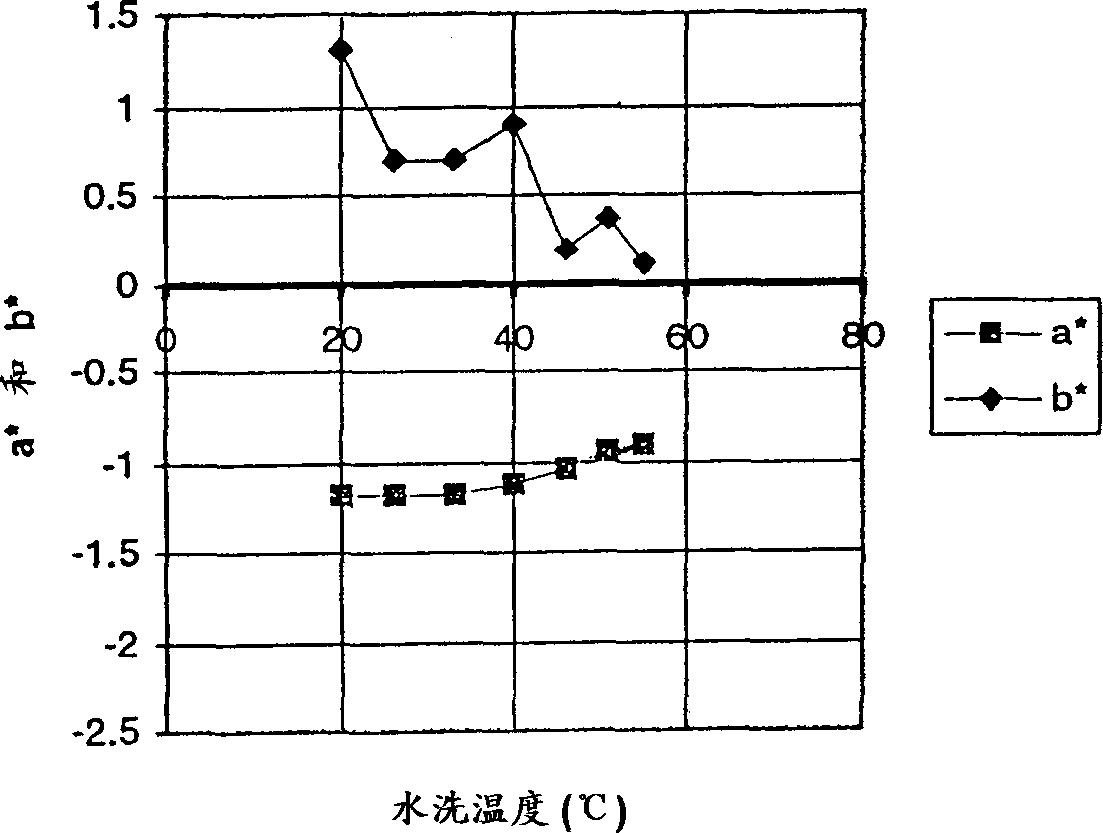

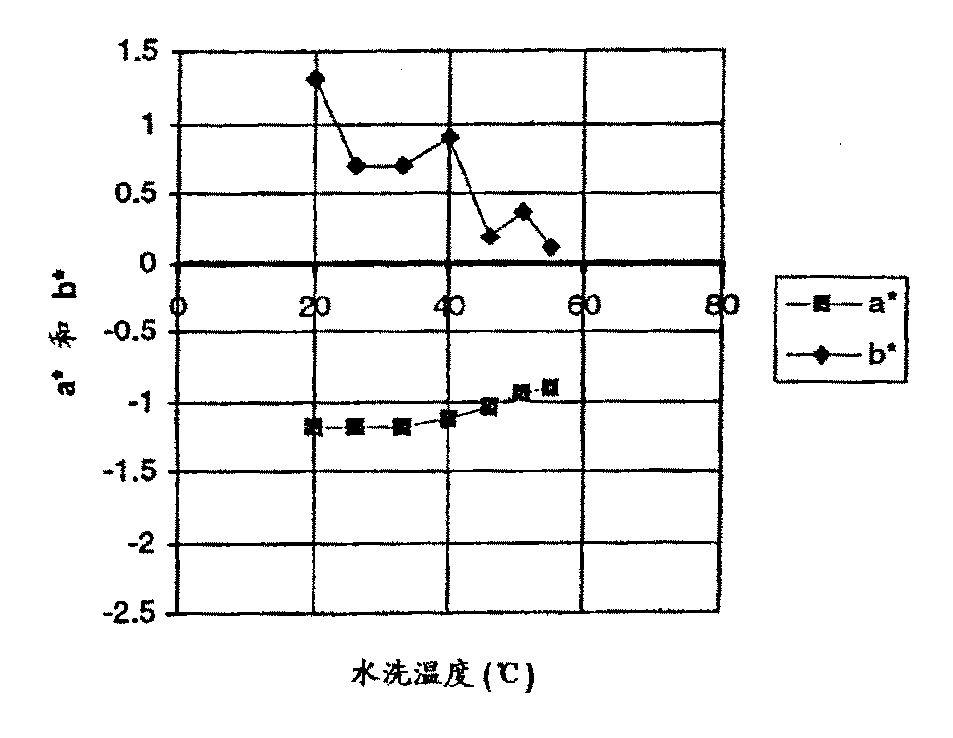

[0053] This example demonstrates the benefit of washing with water at higher temperatures.

[0054] In this example, harsher wash conditions were deliberately used to check the effect of wash water temperature on the amount of stain in color paper. The processing cycles used are shown in Table 5.

[0055] table 5

[0056] Short processing cycle (seconds) temperature (°C)

[0057] Develop 15 40

[0058] Bleaching-fixing (PH5.4) 15 40

[0059] Washing 30 21~55

[0060] The developer used was Kodak Exta Color SM Developer, and the bleach-fix was Kodak Exta Color SM Bleach-Fix (PH 5.4). This condition had a lower pH in the bleach-fix solution than Example 1, which, in combination with the 30 second water wash, resulted in a worse stain profile than the reference. The photo paper used is Ekta Color Edge7.

[0061] Depend on figure 1 It can be seen that as the temperature increases from 22°C to 55°C, b * The average drop was over 1 unit...

Embodiment 3

[0062] Embodiment 3 according to the present invention

[0063] In this example, Phorwite REU was in the first wash tank and the main wash was tested at two different temperatures with the cycle times shown in Table 6.

[0064] Table 6

[0065] Short processing cycle (seconds) temperature (°C)

[0066] Develop 15 40

[0067] Bleaching-fixing (PH5.4) 15 40

[0068] Washing for the first time 5~20 40

[0069] Main Wash 15 37 and 56

[0070] The results are listed in Table 7.

[0071] Table 7 Effect of Phorwite and Final Washing Temperature Samples First Washing Solution Washing Temperature First Washing Total Washing L a * b *

[0072] Time (seconds) Refer to Table 2 for time (seconds). 2g / l) 56 5 20 90.2493 0.149 -0.964147-15 REU (2g / l) 37 10 25 89.95 0.270 -0.512147-19 REU (2g / l) 56 10 25 90 .314 0.086 -0.712

[0073] The data in Table 7 shows that when the final wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com