One division cam mechanism with cambered surface

A cam mechanism and cambered cam technology, which is applied to rotary printing presses, printing presses, labeling machines, etc., can solve the problems of limitation of output accuracy improvement, accumulation of structural errors, and difficulties in processing and manufacturing of plane cam indexing mechanisms. The effect of good rigidity, high precision and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Accompanying drawing is the specific embodiment of the present invention;

[0020] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are described in further detail:

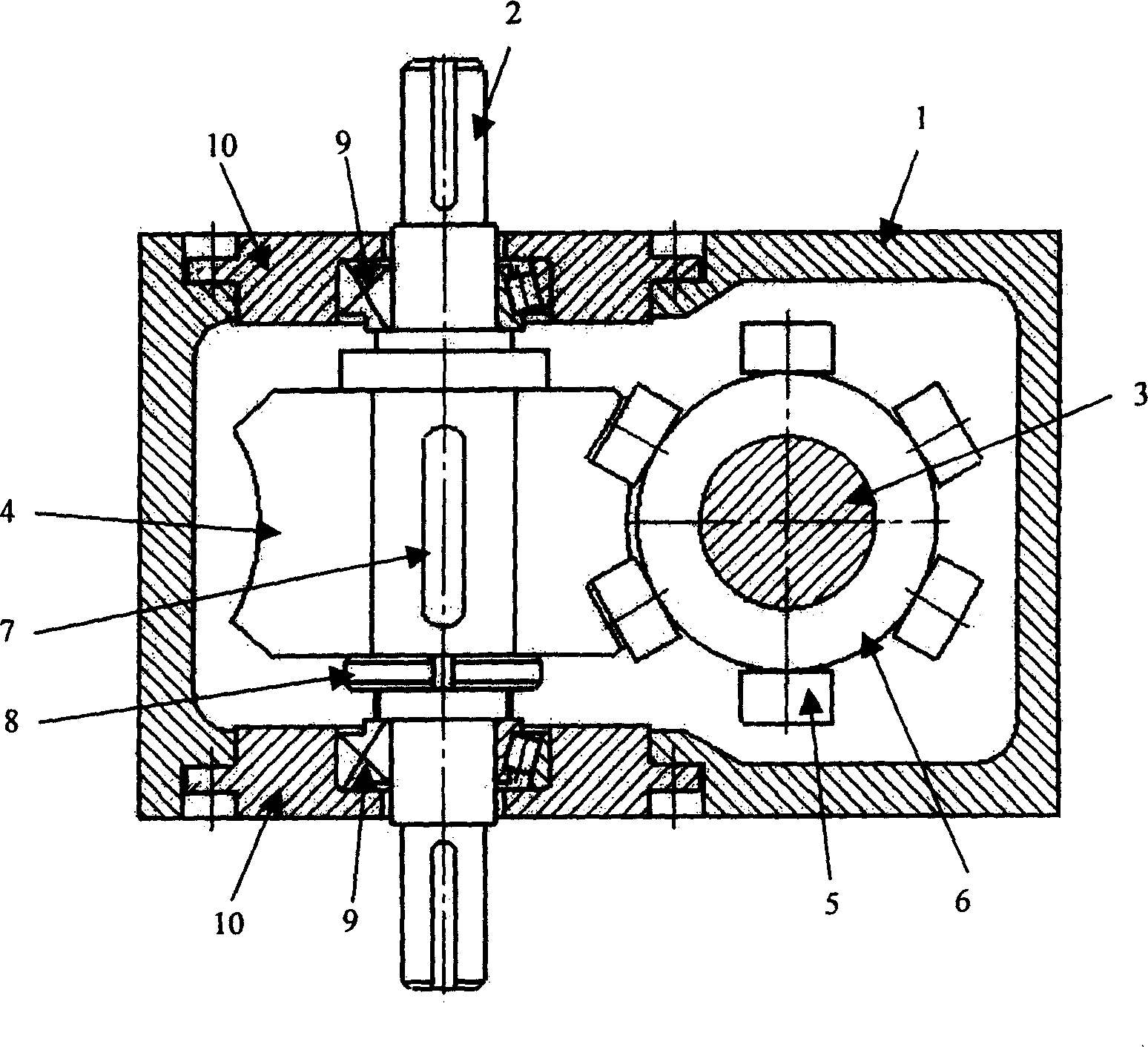

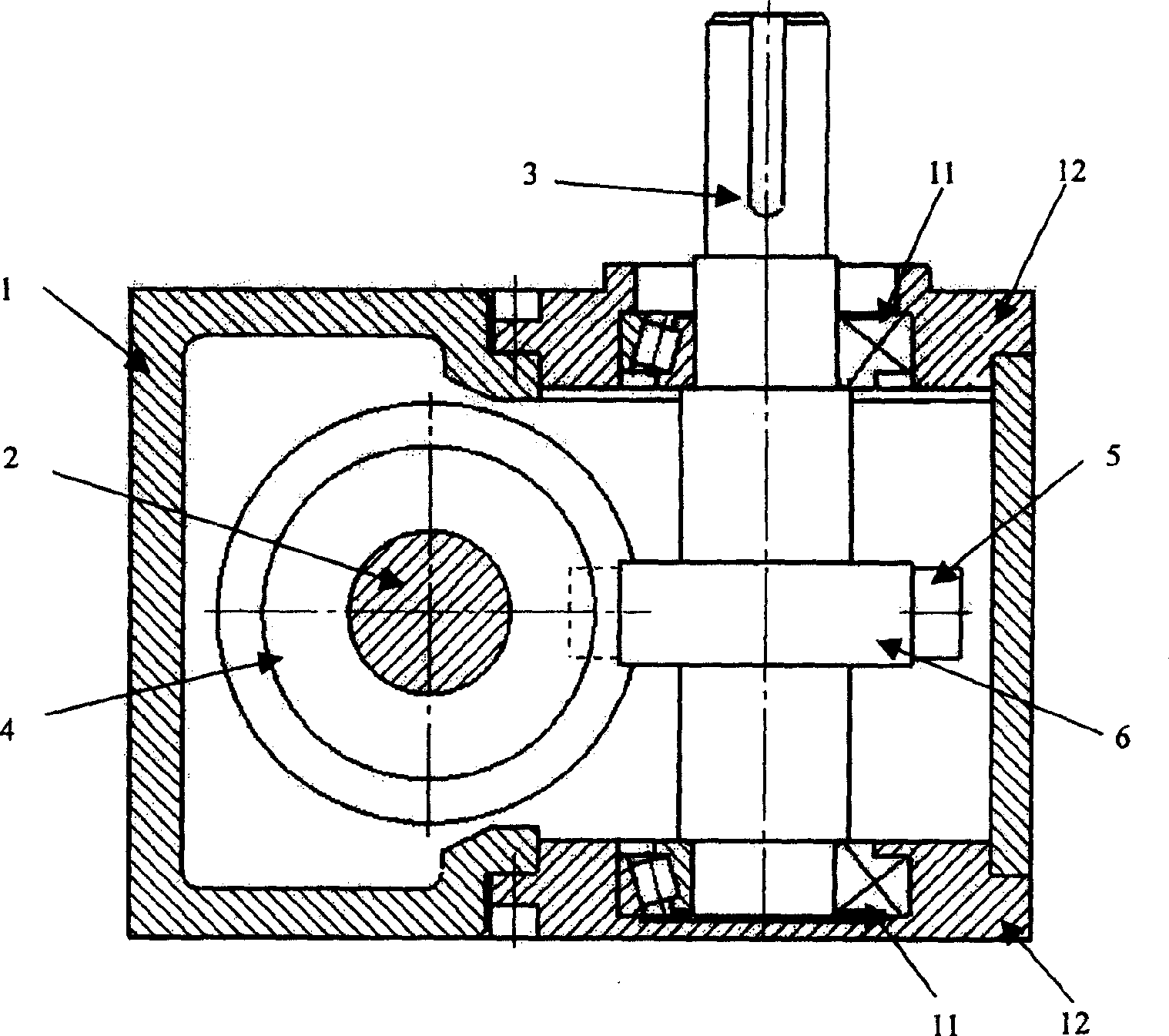

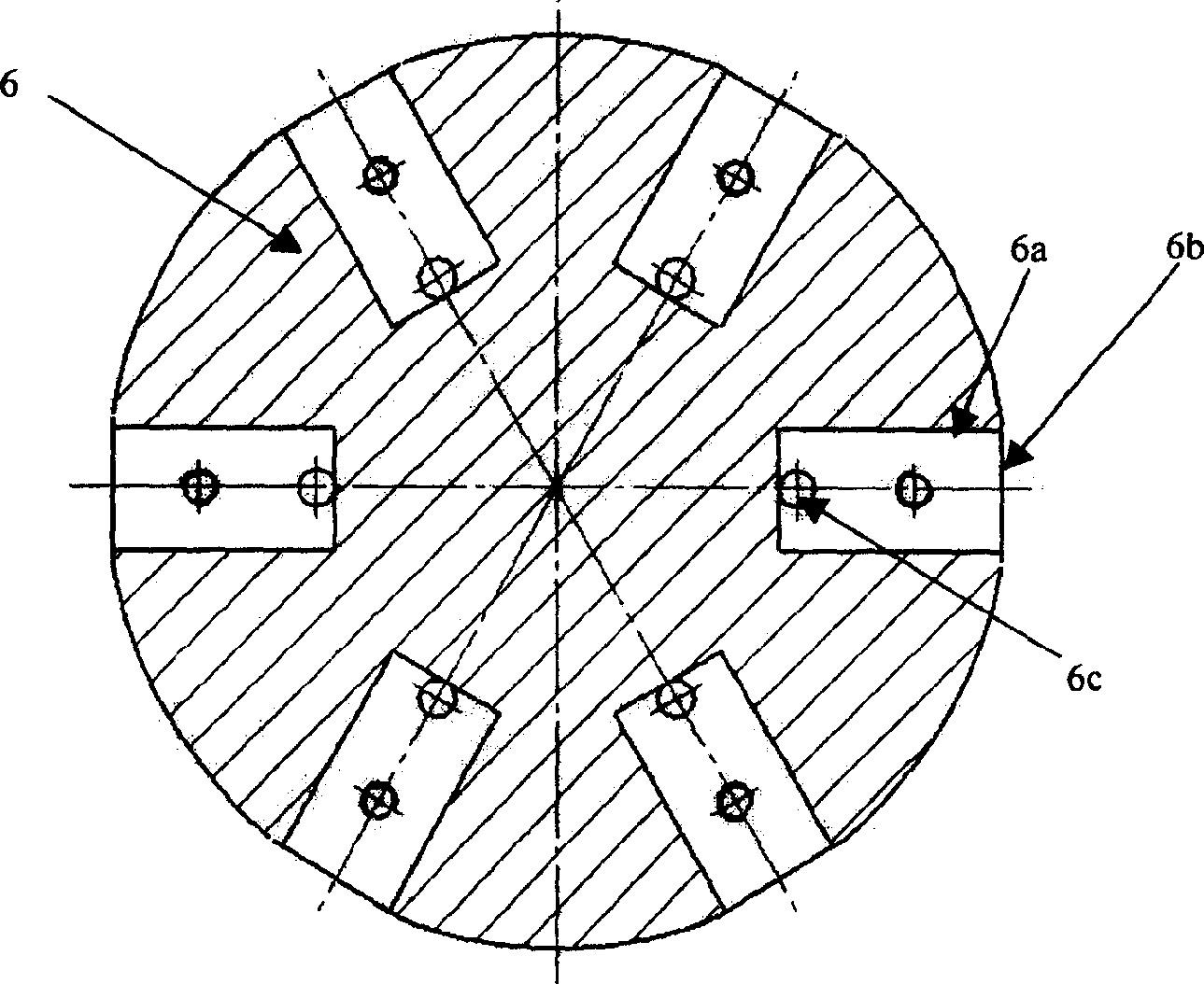

[0021] refer to figure 1 , figure 2 As shown, the present invention includes a base 1 with a rectangular box shape, on which an input shaft 2 and an output shaft 3 are installed, and input and output bearing end covers 10, 12 are respectively arranged on both sides of the base 1, and its characteristics The input shaft 2 has two input ends, the input shaft 2 is fixed with an arcuate cam 4 with six ridges 4a-4f, the arcuate cam 4 is connected to the input shaft 2 by a key 7, and one end of the arcuate cam 4 It is fixed with the shaft shoulder of the input shaft 2, and the other end is locked by the fastener 8. The output shaft 3 is fixed with a driven disc 6, and the driven disc 6 is radially and equally divided and installed to engage wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com