Optical membrane and LCD using same

A technology of optical film and liquid crystal layer, which is applied in the field of optical film and can solve problems such as size change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

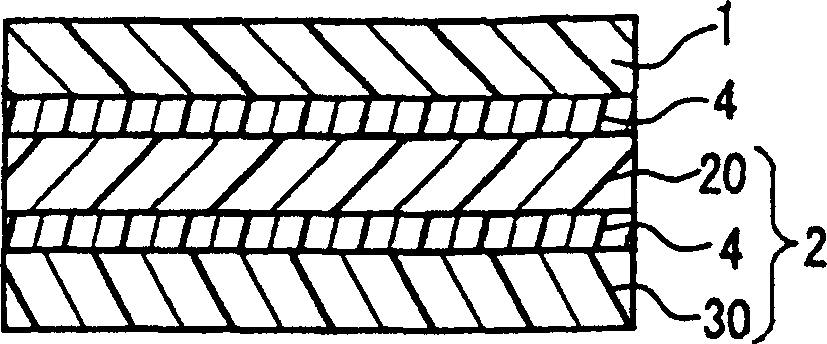

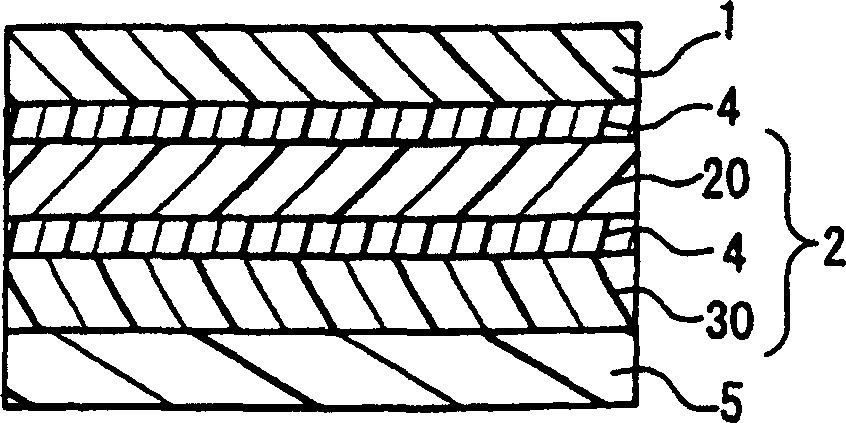

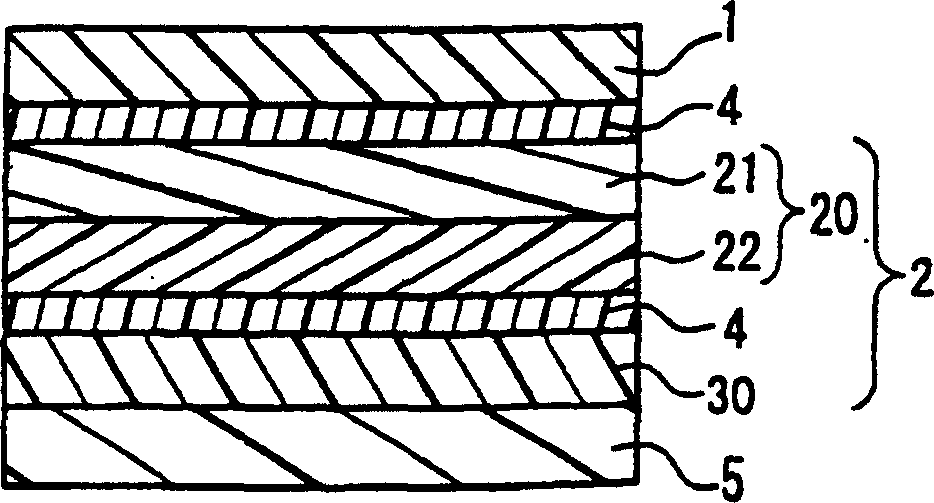

Image

Examples

Embodiment

[0114] The present invention will be further described below by way of examples and comparative examples, and the following examples will not limit the scope of the present invention.

[0115] Embodiment A and comparative example A

Embodiment A-1

[0117] First, a PVA film containing iodine and having a thickness of 30 μm was made into a polarizing plate. A TAC film with a thickness of 40 μm was bonded on both surfaces of the polarizing plate as a transparent protective film with a PVA-based adhesive, and the total thickness of the obtained polarizing plate was 110 μm.

[0118] Thereafter, a brightness enhancement film comprising a circularly polarized light separation layer and a λ / 4 plate was manufactured as follows. First, a cholesteric liquid crystal polymer (prepared according to the method of JP8(1996)-239496A) represented by the following molecular formula (1) was mixed with cyclohexanone to prepare a liquid crystal polymer solution with a concentration of 30% by weight. In formula (1), n:m=80:20, and the molecular weight is about 10000. The polymer solution was coated on an oriented substrate (TAC film) with a thickness of 40 μm, and dried at 160° C. for 2 minutes to form a circularly polarized light separation ...

Embodiment A-2

[0126] A cellulose diacetate film (manufactured by Nitto Denko Corporation) having a thickness of 100 μm and Δnd(450 nm) / Δnd(550 nm)=0.96 was uniaxially stretched to 1.4 times the original length as a λ / 4 plate having a thickness of 80 μm. An optical film with a thickness of 300 μm was produced in a similar manner to Example A-1 except that the λ / 4 plate was changed. The Δnd(450nm) / Δnd(550nm) of gained λ / 4 film and λ / 4 plate are all 0.96, and the photoelastic coefficient of λ / 4 film is 18.4×10 -12 m 2 / N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| photoelasticity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| photoelasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com