Nitride fluorescent powder as well as preparation method and application thereof

A nitride phosphor, phosphor technology, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve problems such as deterioration, and achieve the effects of high reliability and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

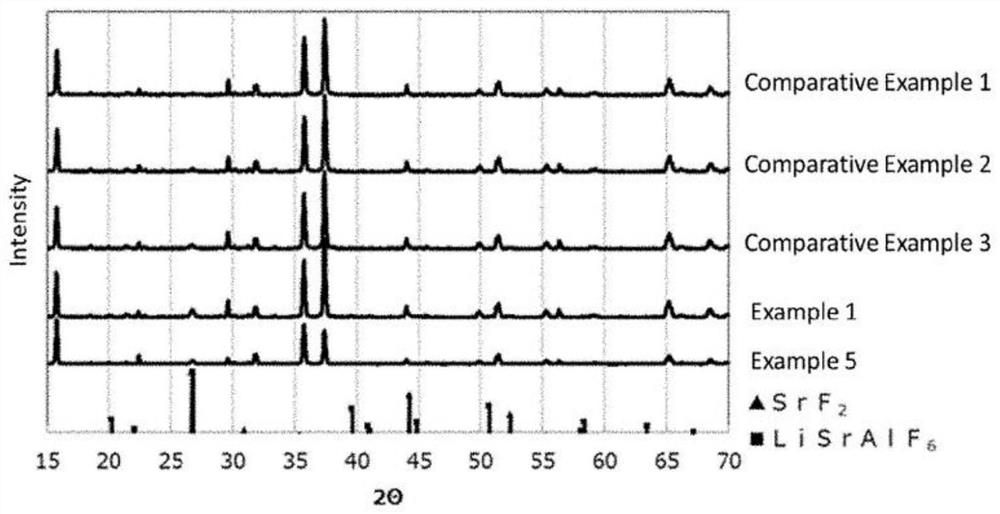

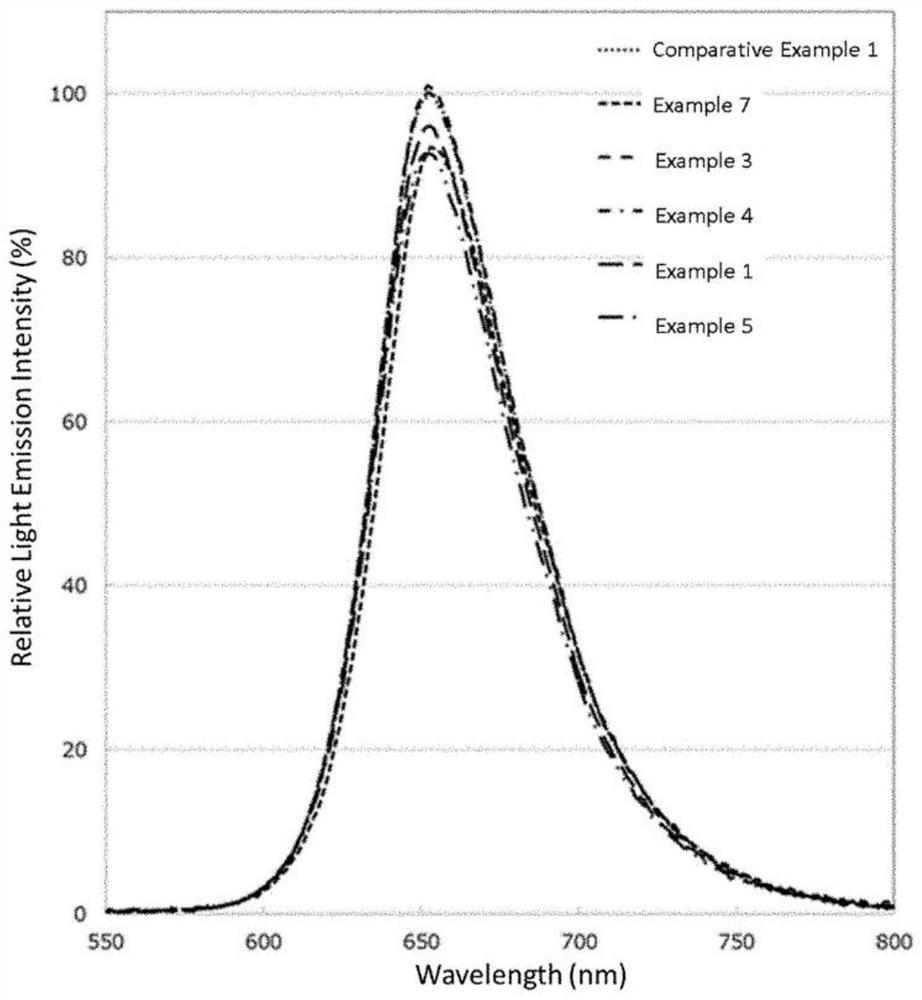

[0025] The preparation method includes the steps of preparing a calcined product having the molecular formula AvBwCxAl3-ySiyNz, contacting the calcined product with a fluorine-containing substance and heat-treating the calcined product at a temperature of 200°C or higher and 500°C or lower.

[0026] The parameter v is preferably 0.90 or higher, 1.00 or lower, preferably 0.90 or higher, 1.00 or lower, from the viewpoint of stability of the crystal structure. The parameter x represents the activation amount of at least one element selected from the group consisting of Eu, Ce, Tb, and Mn, which can be properly selected to achieve the target characteristics. The parameter x preferably satisfies 0.001<x≦0.020, preferably satisfies 0.002≦x≦0.015.

[0027] The core part of the fluorescent material is a mixture fired in a nitrogen atmosphere. For example, firing can be performed using a gas pressurized electric furnace. The firing temperature may be 1,000°C or above and 1,400°C or b...

Embodiment 1

[0053] A fluorescent material containing strontium, lithium, europium, aluminum and N was prepared. Specifically, for a fluorescent material composed of the formula AvBwCxAl3-ySiyNz, where A is Sr, B is Li, C is Eu, SrNu (where u corresponds to 2 / 3, is Sr 2 mixture of N and SrN), using SrF 2 ,, LiAlH 4 , AlN and EuF 3 as material. In this example, the parameter y in the formula is 0. The materials were weighed so that the molar ratio of Sr / Li / Eu / Al was 0.9925 / 1.2000 / 0.0075 / 3.0000, and then mixed in a glove box in an inert atmosphere to obtain a material mixture. SrNu and SrF 2 The mass ratio is 94 / 6. Since Li (lithium) has a tendency to fly during the baking process, the amount of Li (lithium) is greater than the theoretical value. The material mixture was charged in a crucible and heat-treated in a nitrogen atmosphere at a gas pressure of 0.92 MPa gauge (1.02 MPa absolute) at a temperature of 1100 °C for 3 hours to provide a calcined product of material composition Sr ...

Embodiment 2

[0057] A nitride fluorescent material in powder form was prepared in the same manner as in Example 1, except that the temperature was changed to 250°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com