Radiation fin array cooler

A heat sink cooling and heat sink technology, applied in cooling/ventilation/heating renovation, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of complex mechanical process, reduction of heat sinks, and reduction of the number of heat sinks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the following detailed description and in the several figures of the drawings, like parts bear the same reference numerals.

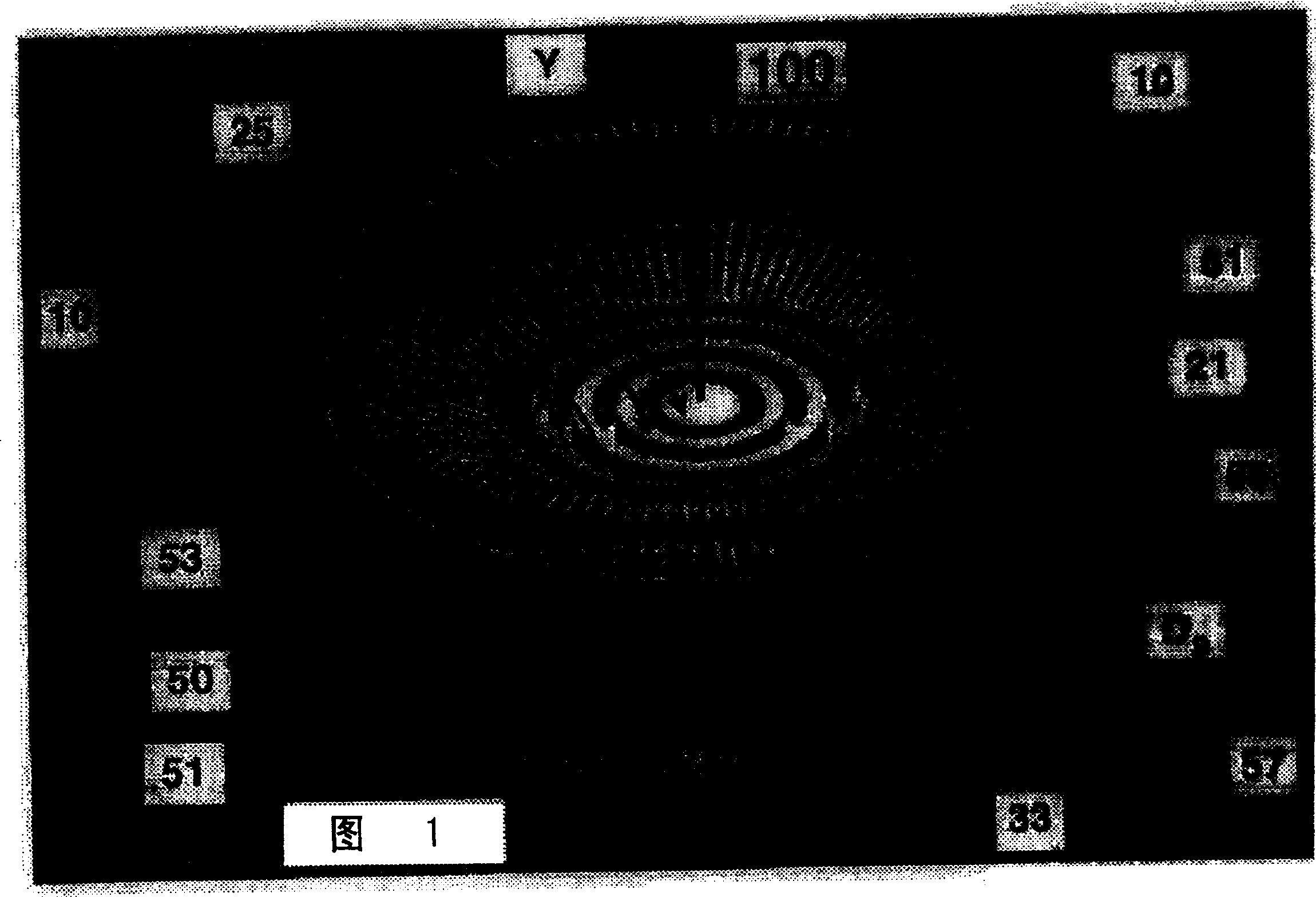

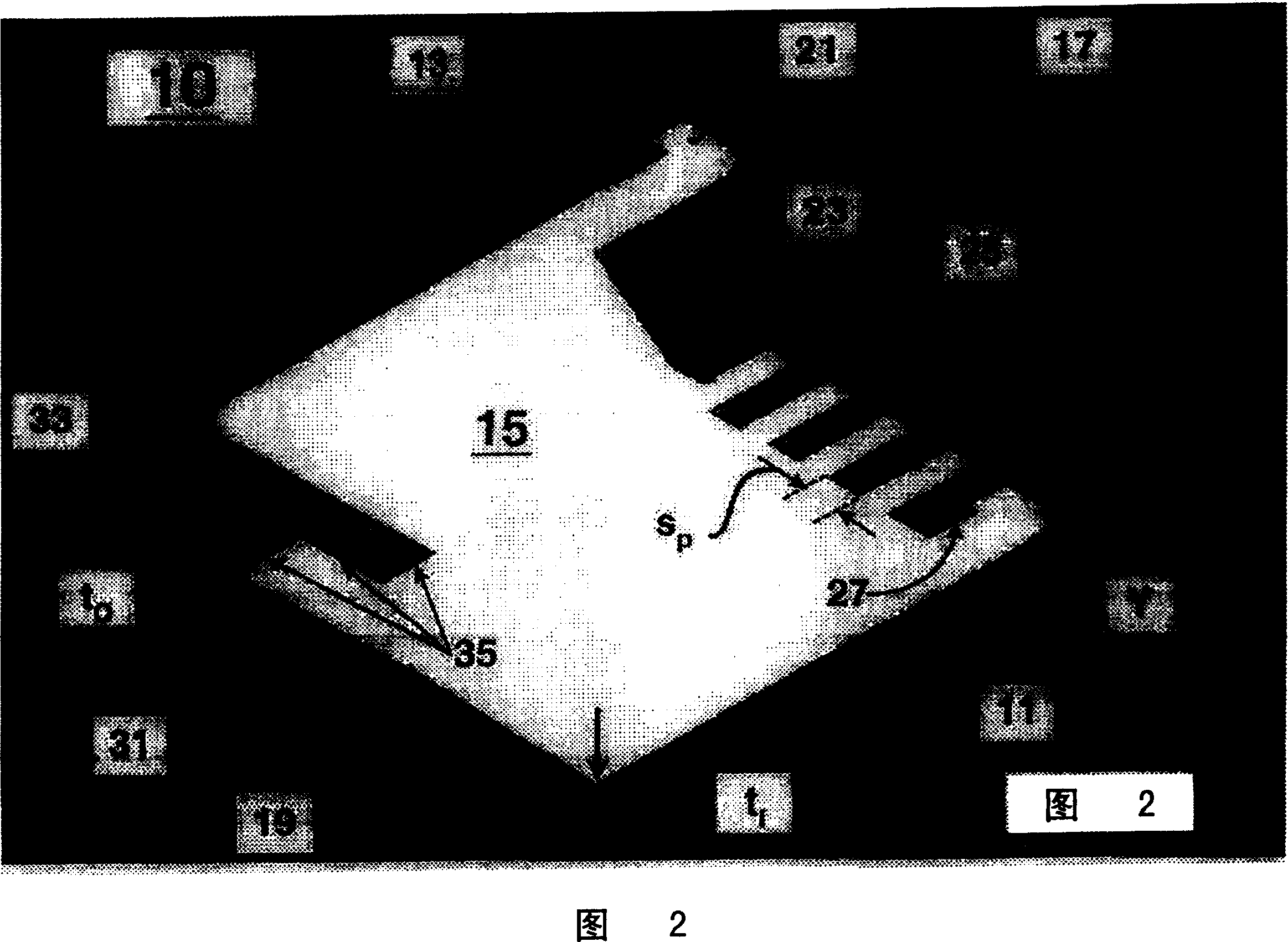

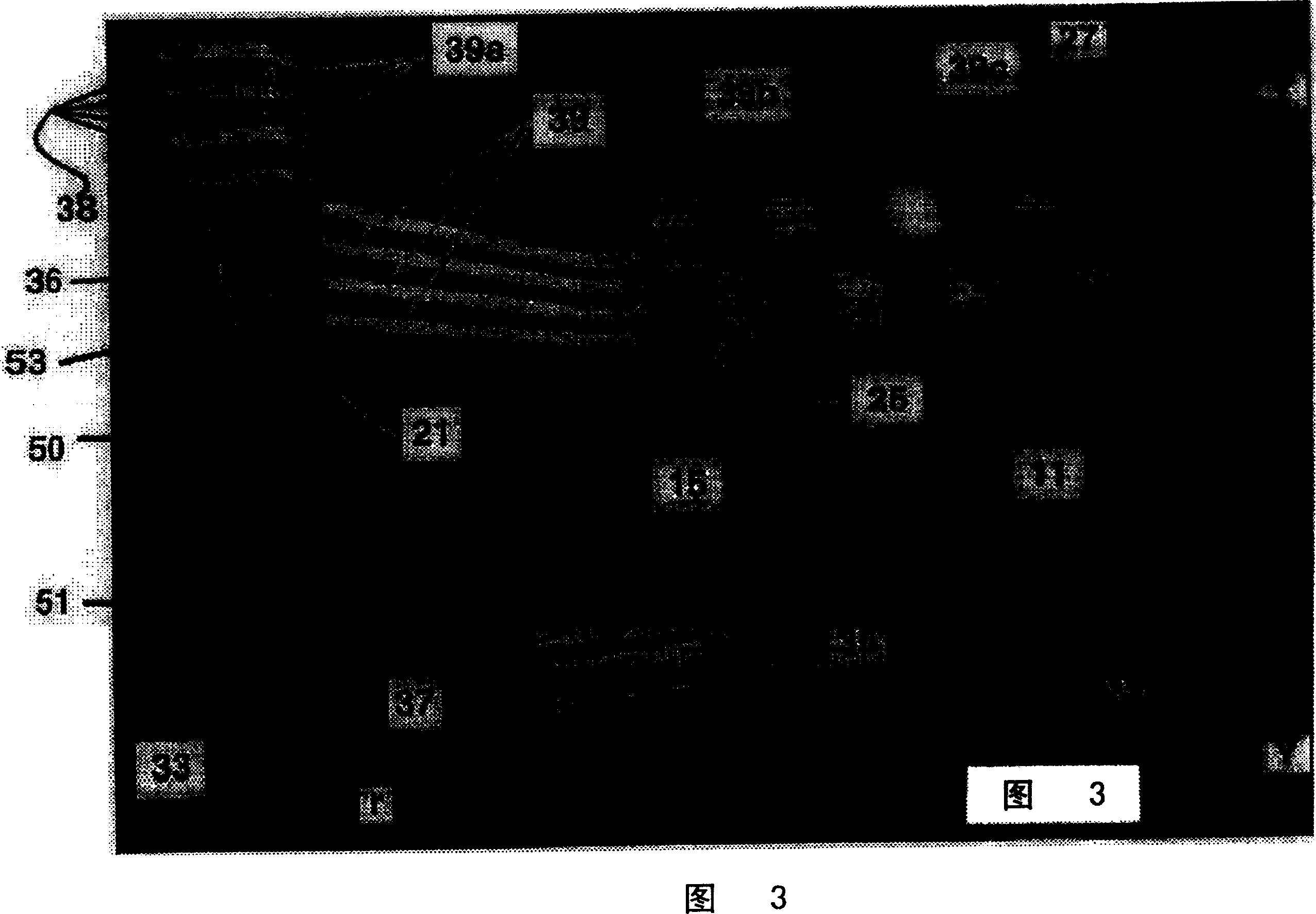

[0034] For purposes of illustration, and as shown, the present invention relates to a discrete fin array cooling system for dissipating heat from a component. The fin array cooling system includes a plurality of separate cooling fins. That is to say, the array cooling system includes a plurality of independent cooling fins, and these cooling fins are combined to form the array cooling system.

[0035] Each separate cooling fin includes an inner edge, an outer edge, and cooling surfaces disposed opposite each other and spaced apart by a gradually decreasing distance from the outer edge to the inner edge. Each cooling fin also includes a leading edge and a trailing edge. The cooling fins are mounted in a radial array, the fins are connected to one another along their respective portions of the cooling surface, and their inner edges are dispose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com