Arm beam type flash raster optical modulator and array

A light modulator and cantilever beam type technology, applied in the field of beam modulation devices, can solve the problems of affecting the diffraction efficiency of gratings, unable to form an area array structure, reducing device contrast, etc., to increase the blazing area, easy area array, and large effective area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

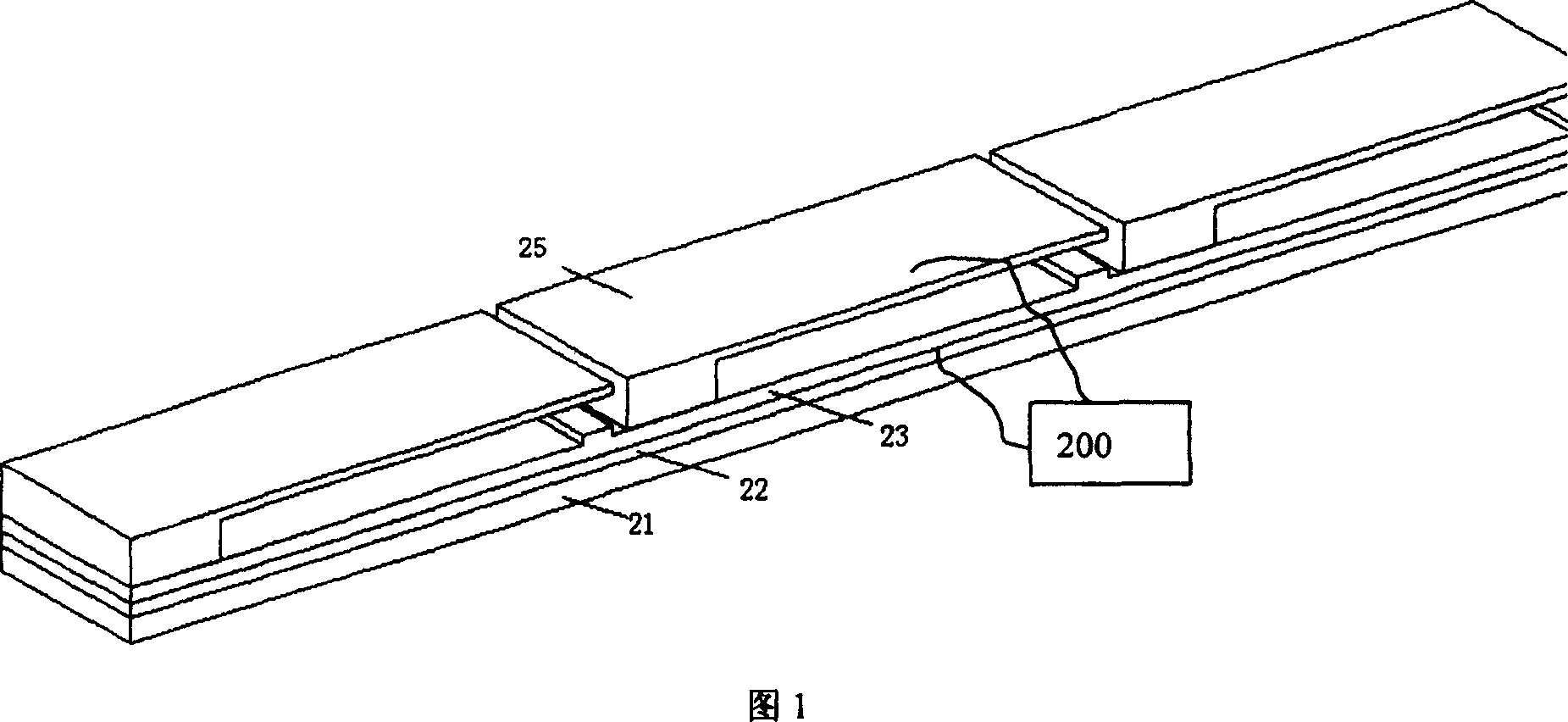

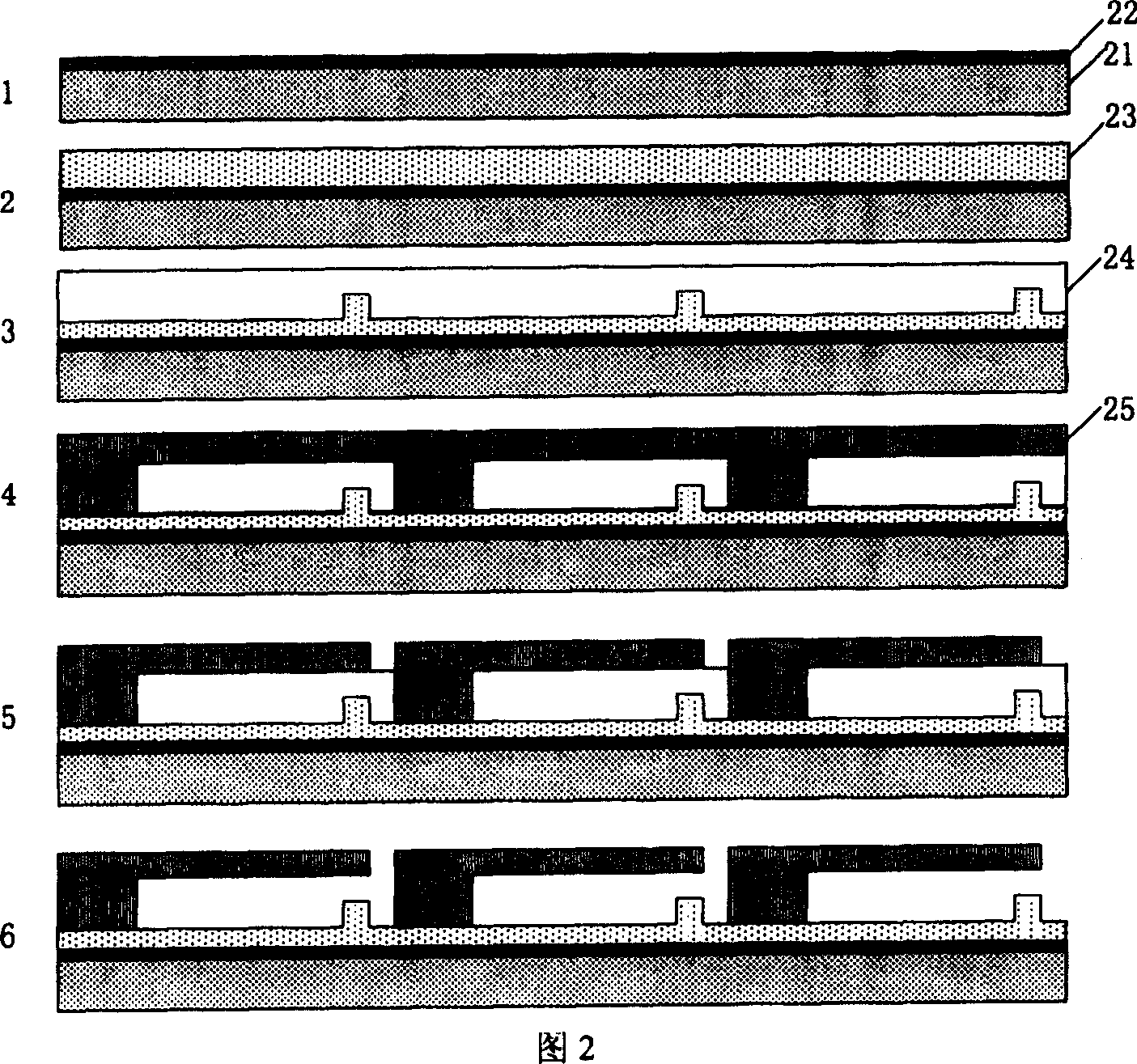

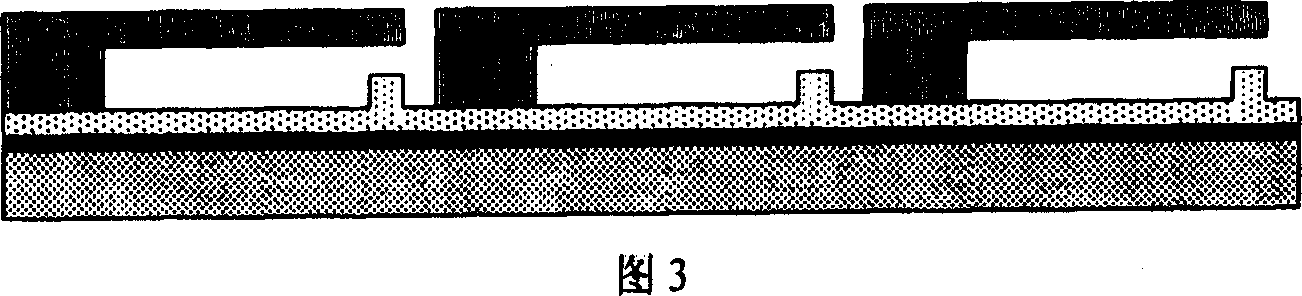

[0025] Referring to Figures 1 and 2, the cantilever beam blazed grating optical modulator has the following composition structure: a substrate 21 and an electric drive device 200, on which a lower electrode layer 22 and an insulating layer 23 are sequentially formed, and a multi-layer suspended above the insulating layer A strip 25 having a reflective surface with a cantilever beam structure, with a gap between the insulating layer 23 and the strip 25, these strips 25 are supported on the base by each end to form a cantilever beam structure . The driving circuit 200 is connected to the upper and lower electrodes through wires, and the driving circuit 200 adopts existing mature technology in the field, and mostly adopts voltage driving. According to different array requirements, use parallel or serial drive mode. At the same time, the electrode lead-out wires of the driving circuit can be obtained while making the structure. When the driving circuit 200 in FIG. 1 applies a pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com